Batch process fault monitoring method based on multi-stage ICA-SVDD

An ICA-SVDD, fault monitoring technology, applied in electrical testing/monitoring, testing/monitoring control systems, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

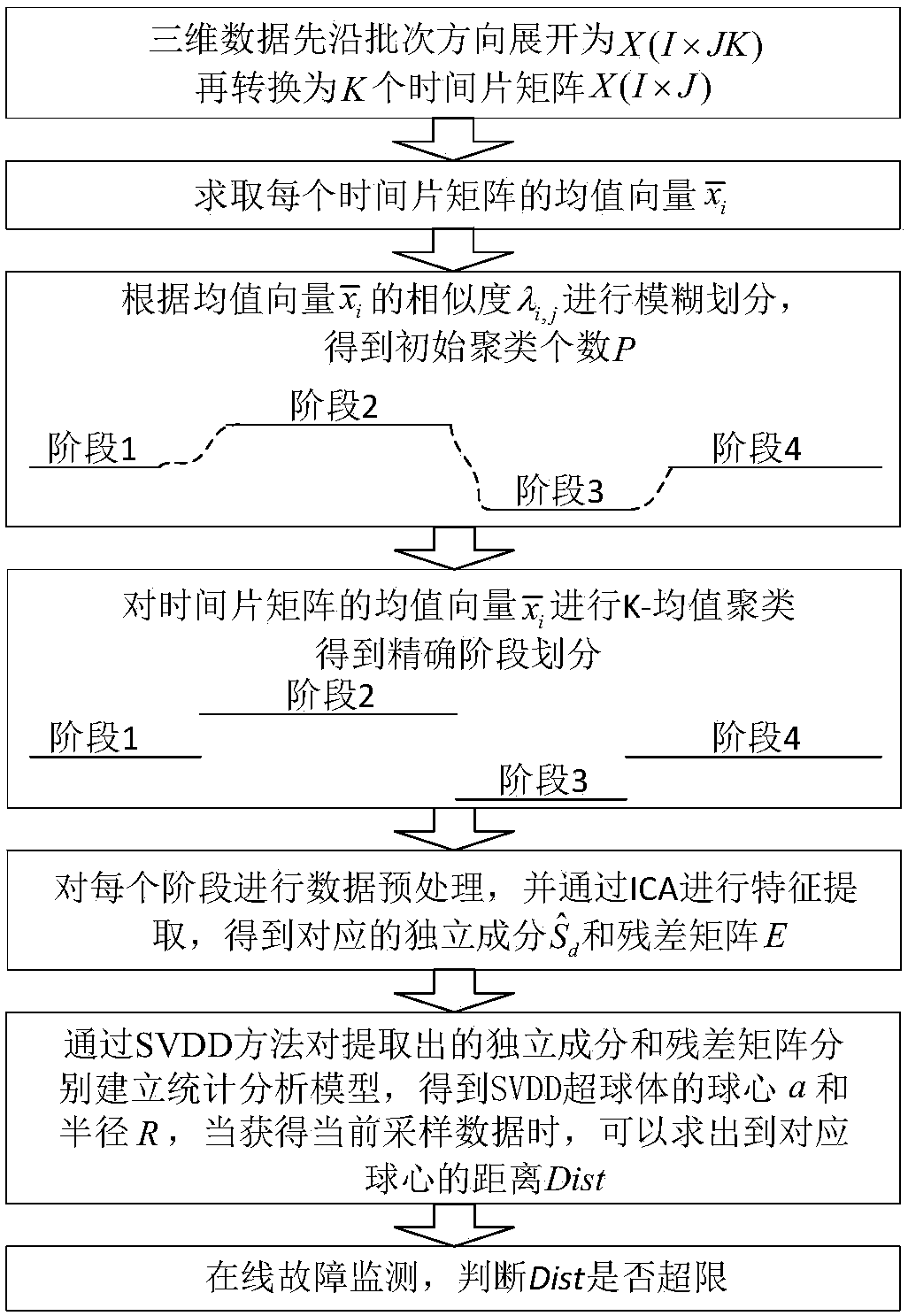

[0018] Combine below figure 1 Shown, the present invention is described in further detail:

[0019] The research data used is collected from an actual semiconductor etching process, and the fault monitoring is carried out on the normal data and fault data of semiconductor etching respectively.

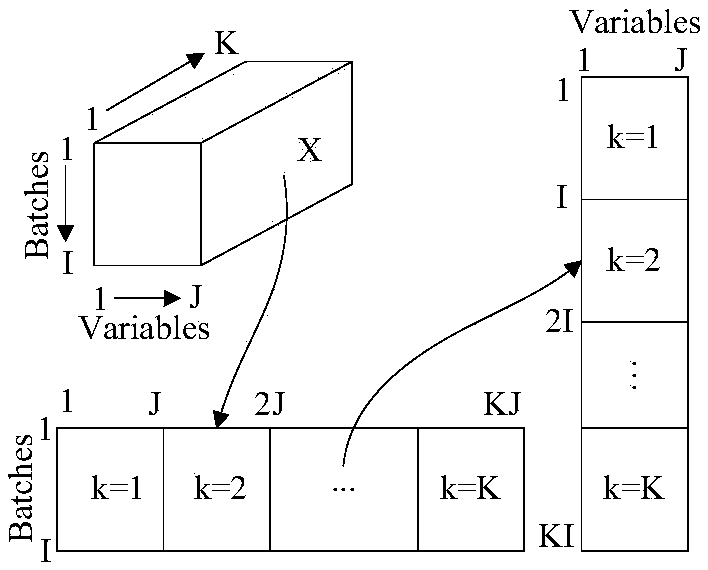

[0020] Step 1: Two-dimensional expansion of the three-dimensional data set X (I×J×K) of the batch process, where I represents the number of batches, J represents the number of variables, and K represents the number of sampling points. Using the data processing method that combines the batch direction and the variable direction, the three-dimensional data X (I×J×K) is first transformed into a two-dimensional matrix X(I×KJ) along the batch direction, and then the two-dimensional matrix; and then recombine according to the variable direction to form a new two-dimensional matrix X(KI×J). Two-step data expansion method such as figure 2 shown.

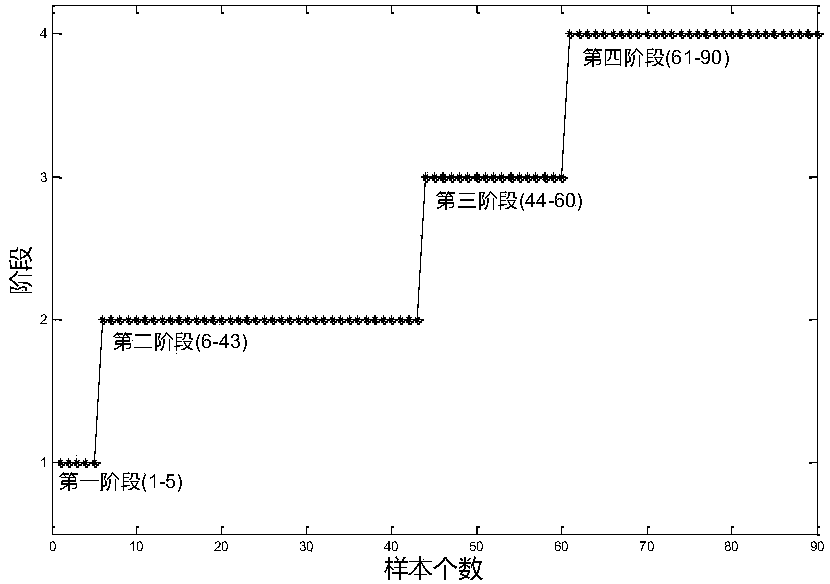

[0021] Step 2: Carry out reasonable stage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com