Gear drive reliability assessment method based on Kriging model

A gear transmission and reliability technology, applied in CAD numerical modeling, special data processing applications, instruments, etc., can solve the problems of less research on reliability evaluation, and achieve the effect of reducing the number of tests and the amount of calculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to facilitate those skilled in the art to understand the technical content of the present invention, the content of the present invention will be further explained below in conjunction with the accompanying drawings.

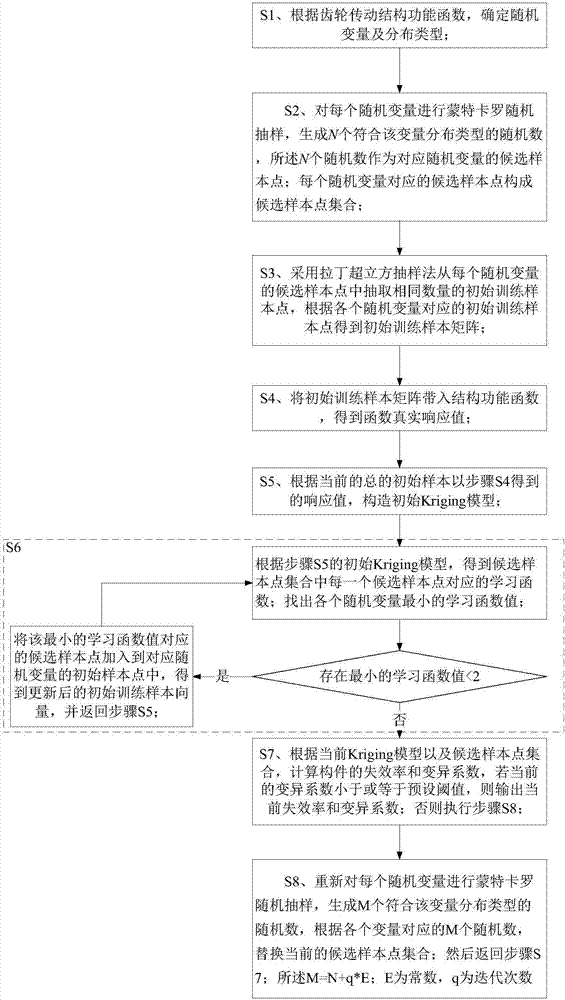

[0035] The technical scheme of the present invention is as figure 1 Shown; a gear transmission reliability assessment method based on the Kriging model, including the following steps:

[0036] S1: Establish the function function of the gear transmission structure, and determine the random variable S=[x in the function 1 ,x 2 ,...,x n ] T and distribution type.

[0037] The structure function function is:

[0038] G(x)=D 0 -D(x) (1)

[0039] Among them, D 0 Structural strength, D(x) structural stress; the structure function function here can also be approximated by the existing Kriging model to simplify the calculation.

[0040] The distribution types of each random variable are obtained through data collection and hypothesis testing.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com