feed feeding machine

A feeding machine and feed technology, applied in the field of aquaculture, can solve the problems of easy agglomeration, low efficiency and unevenness of the feed, and achieve the effects of rapid and large-scale feeding work, improving work efficiency and reducing equipment costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

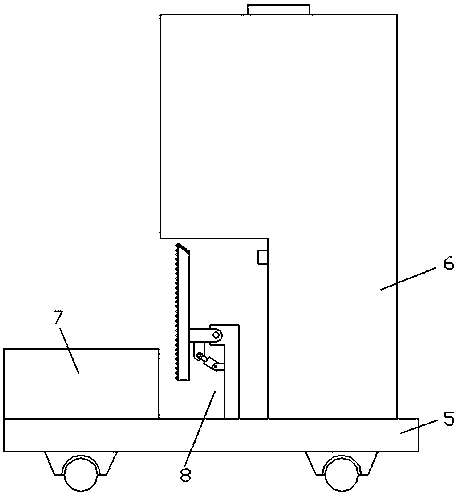

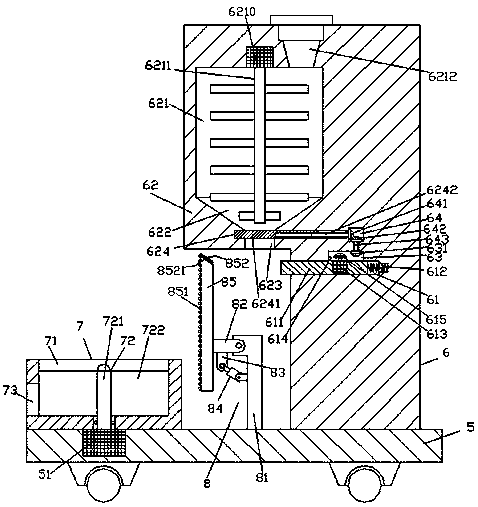

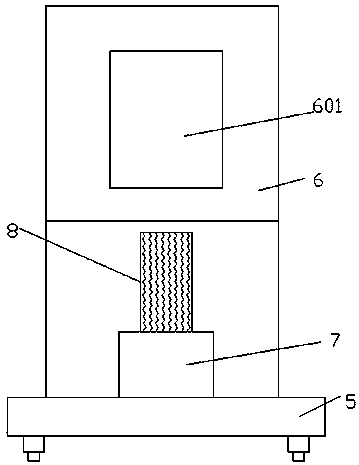

[0019] like Figure 1-Figure 5 As shown in the figure, a feed feeding machine of the present invention includes a base 5, a feeding cabinet 7 installed on the top of the base 5, and a proportioning mixing part 6, and the feeding cabinet 7 is proportional to the The top of the machine base 5 between the mixing parts 6 is provided with a conveying part 8 , and the top left side of the mixing part 6 is provided with a convex end wall 62 , and the convex end wall 62 is located above the conveying part 8 The convex end wall 62 is provided with a feed accommodating cavity 621, the bottom of the feed accommodating cavity 621 is provided with a conical cavity 622, and the bottom of the conical cavity 622 is provided with an outlet 623 extending downward, The bottom of the outlet 623 extends through the bottom end face of the convex end wall 62 , and a sliding groove 624 extending from left to right extends through the outlet 623 , and the left extending section of the sliding groove 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com