Preparation method of ready-to-eat nutrition-enhanced cyperus esculentus powder

A technology of nutrition enhancement and sesame bean powder is applied in the functions of food ingredients, food science, food ingredients, etc. to achieve the effects of good flavor, long fresh-keeping period and simple process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

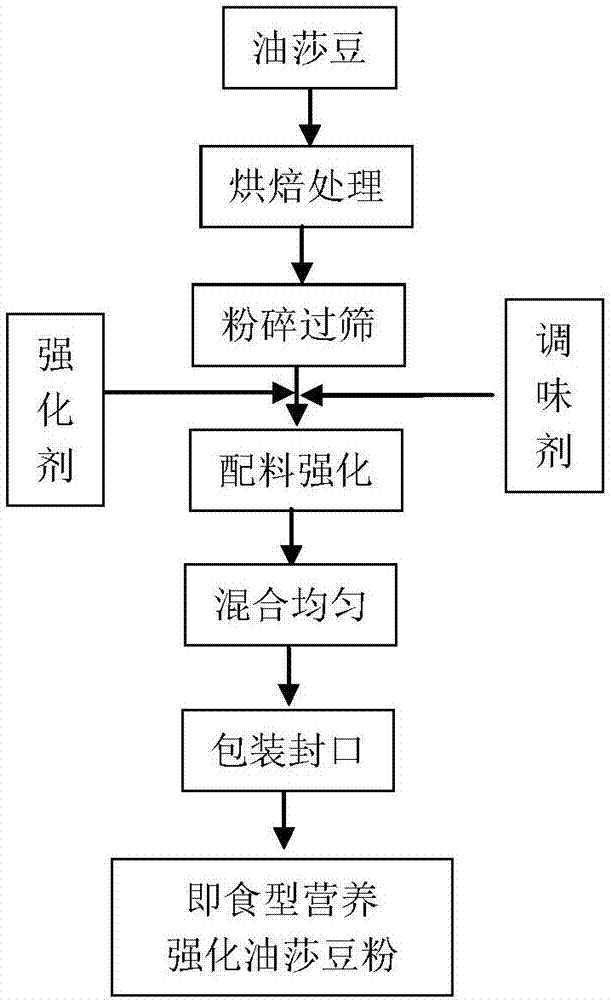

[0035] A kind of preparation method of ready-to-eat nutrition-fortified oily bean powder, its steps are:

[0036] ⑴Roasting treatment: Take 3kg of peeled oily beans, put them into the baking tray of the baking box, heat the baking box to 120°C, and keep it at 120°C, bake the oily beans for 1.5 hours, so that the oily beans are fully matured, take out , air-cooled to room temperature, 2.85kg of mature oily beans was obtained for subsequent use.

[0037] (2) Crush and sieve: Take the ripened oily soybeans, crush them with a stainless steel grinder and sieve through a 120-mesh standard sieve to obtain mature oily soybean powder for later use.

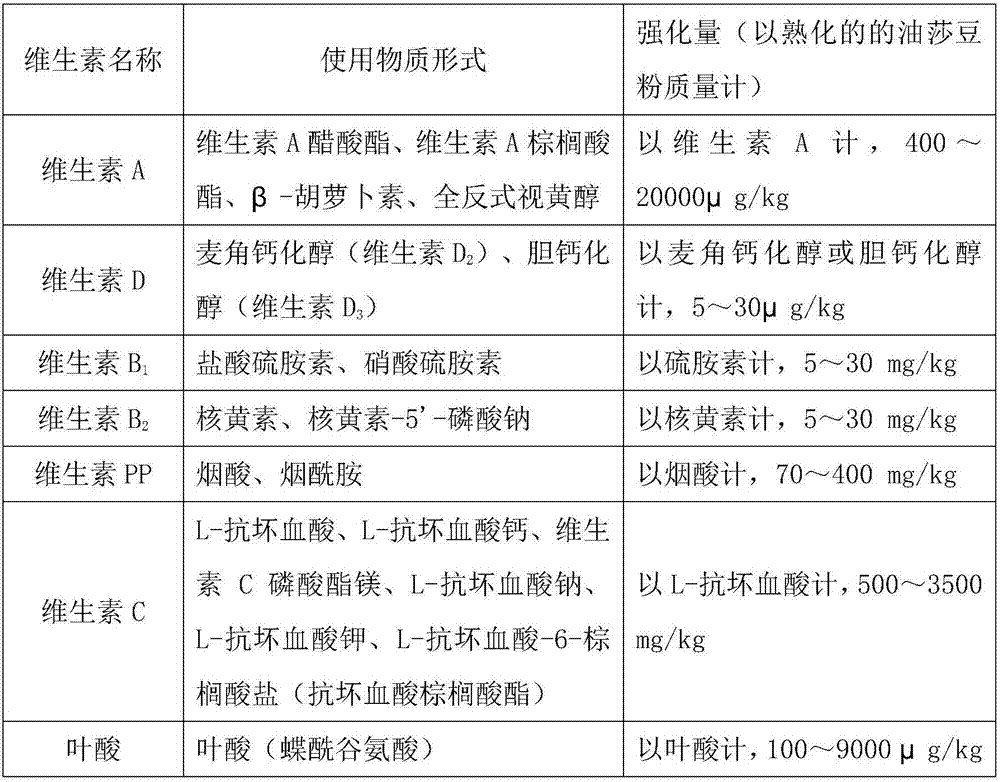

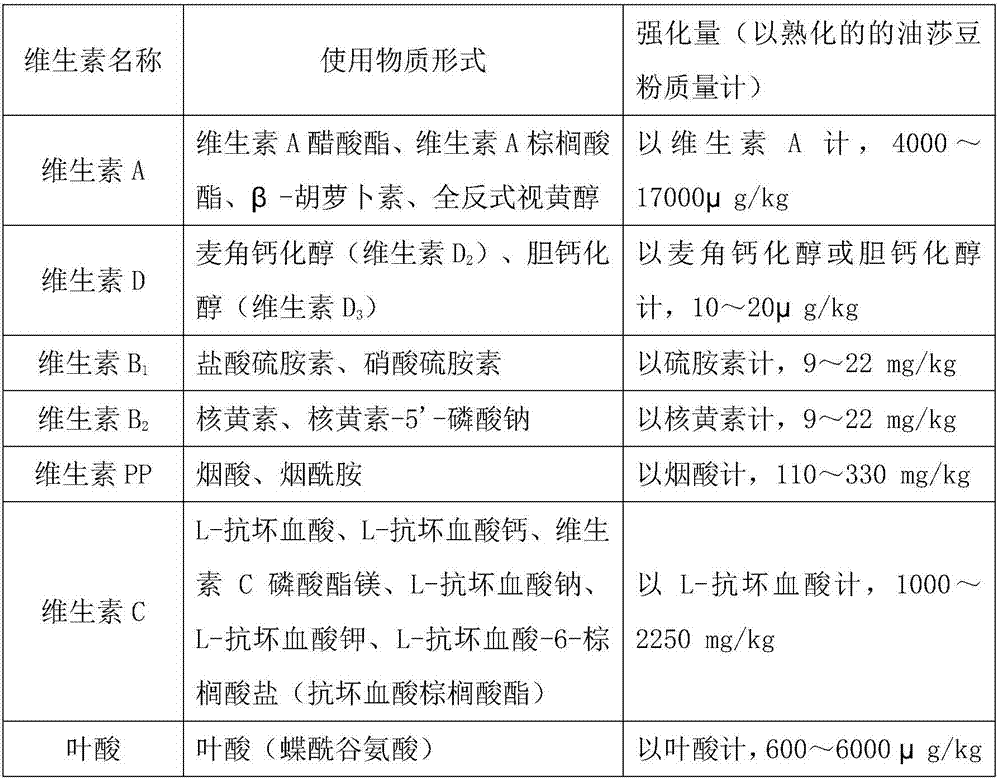

[0038] (3) Strengthening and mixing of ingredients: Take 2.85kg of matured soybean powder obtained in step (2) and put it in a powder mixer; grind the brown sugar and citric acid and sieve through a 120-mesh standard sieve for later use; weigh the corresponding Quality brown sugar powder, citric acid powder, and vitamin A, vitamin D, and ...

Embodiment 2

[0043] A kind of preparation method of ready-to-eat nutrition-fortified oily bean powder, its steps are:

[0044] (1) Baking treatment: Take 15.5kg of peeled oily beans, put them into the baking tray of the baking box, heat the oven to 115°C, and keep it at 115°C, bake the oily beans for 2.5 hours, so that the oily beans are fully matured, Take it out, air-cool to room temperature, and get 14.7kg of matured oily beans for later use.

[0045] (2) Crushing and sieving: Take the matured oily soybeans, crush them with a stainless steel grinder, and sieve through a 100-mesh standard sieve to obtain mature oily soybean powder for later use.

[0046] (3) Intensify and mix the ingredients evenly: take 14.7kg of the matured soybean powder obtained in step (2) and put it in a powder mixer; grind the white sugar, xylitol and malic acid and sieve them through a 100-mesh standard sieve for later use; Weigh white granulated sugar, xylitol and malic acid powder of corresponding quality and ...

Embodiment 3

[0051] A kind of preparation method of ready-to-eat nutrition-fortified oily bean powder, its steps are:

[0052] (1) Baking treatment: Take 9.6kg of peeled oily beans, put them into the baking tray of the baking box, heat the baking box to 120°C, and keep it at 125°C, bake the oily beans for 1 hour, so that the oily beans are fully matured, Take it out, cool it to room temperature by air, and get 9.12 kg of mature oily beans for later use.

[0053] (2) Crush and sieve: Take the ripened oily soybeans, crush them with a stainless steel grinder and sieve through a 200-mesh standard sieve to obtain mature oily soybean powder for later use.

[0054] (3) Strengthening and mixing of ingredients: Take 9.12kg of the matured soybean powder obtained in step (2) and put it in a powder mixer; grind the white sugar, maltitol, citric acid and fumaric acid after crushing and sieving through a 200-mesh standard sieve for later use; Weigh the white granulated sugar, maltitol, citric acid and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com