High-temperature dust removing device

A high-temperature dust removal and box technology, applied in transportation and packaging, dispersed particle filtration, gas treatment, etc., can solve the problems of unfavorable energy, high operating cost, shortened service life, etc., and achieve thermal fatigue resistance, porosity, dust removal and denitrification Integration, the effect of increasing dust removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

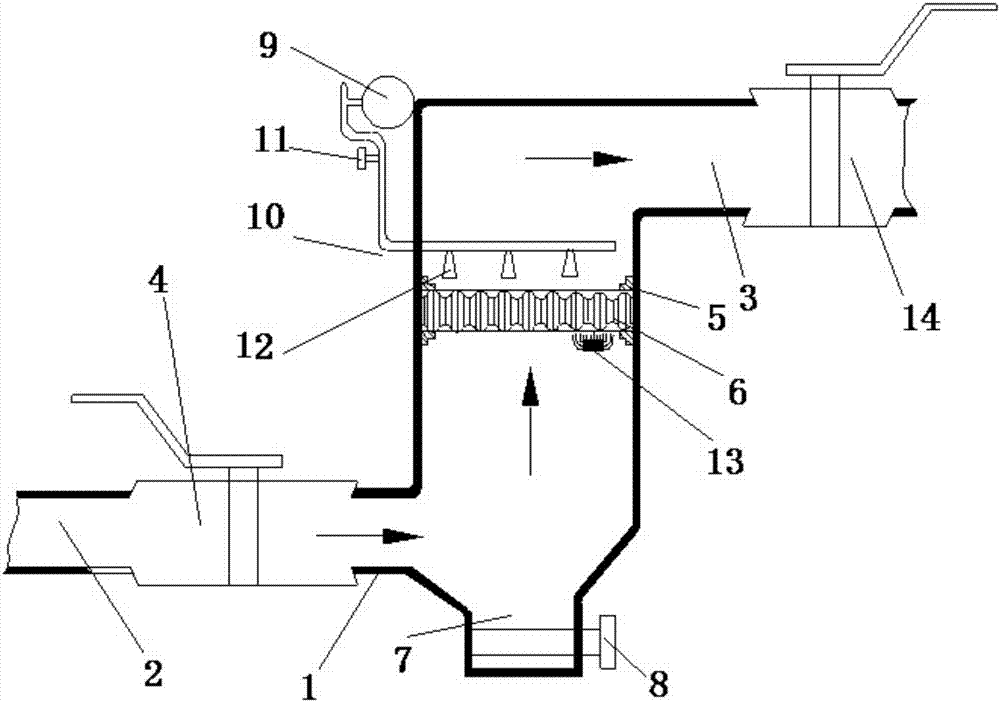

[0014] Preferred embodiment 2, this preferred embodiment discloses a high-temperature dust removal pipe, which is basically the same as the device described in the preferred embodiment 1, the difference is that: the box body 1 is also equipped with a back-blowing soot assembly, and the back-blowing soot The soot blowing assembly includes an air pump 9 arranged outside the box 1, a conduit 10 and a regulating valve 11 connected to the conduit 9. One end of the conduit 10 is connected to the air pump 9, and the other end is connected to the box 1. At the same time, the conduit 10 is provided with a blowing port 12. The blowing port 12 partially extends into the ceramic fiber filter plate. Use a small air pump to provide high-pressure gas, and the gas will lead to the ceramic fiber filter plate 6 through the blowing port 12 on the conduit 10, and the dust attached to the ceramic fiber filter plate 6 will be blown off to prevent excessive accumulation on the ceramic fiber filter pl...

Embodiment 3

[0015] Preferred embodiment 3, this preferred embodiment discloses a high-temperature dust removal pipe, which is basically the same as the device described in the preferred embodiment 2, the difference is that: the fixed seat 5 is also on the side close to the air inlet 2 A soot cleaner 13 is provided, and the soot remover 13 is a vibrating soot cleaner, a sonic soot cleaner, a steam soot remover or an electric brush soot remover, and the soot remover 13 can remove the dust attached to the ceramic fiber filter plate , to prevent the ceramic fiber filter plate from clogging due to excessive dust, and achieve the same effect as that of the preferred embodiment 2. A soot remover 13 can be set beside each ceramic fiber filter plate 6, or only a soot remover 13 is set on the ceramic fiber filter plate 6 closest to the air inlet 2. Preferably, the soot cleaner 13 is a vibrating soot cleaner, because the dust particles in the gas to be treated are very small, and the dust on the cer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com