A method to improve the reliability of engine cylinder head and silicon solid solution strengthened ferritic vermicular graphite cast iron

A technology for engine cylinders and vermicular graphite cast iron, which is applied to engine components, machines/engines, cylinder heads, etc., can solve problems such as increased hardness difference, poor casting performance, and reduced processing accuracy, and achieves low shrinkage tendency of molten iron and high processing performance. Excellent, guaranteeing the effect of machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

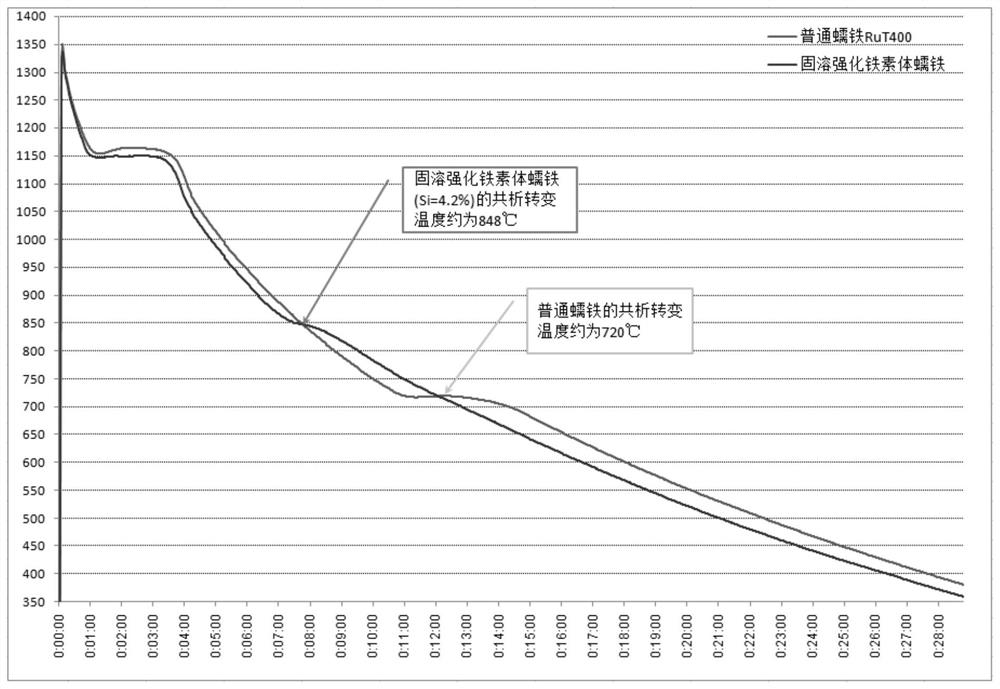

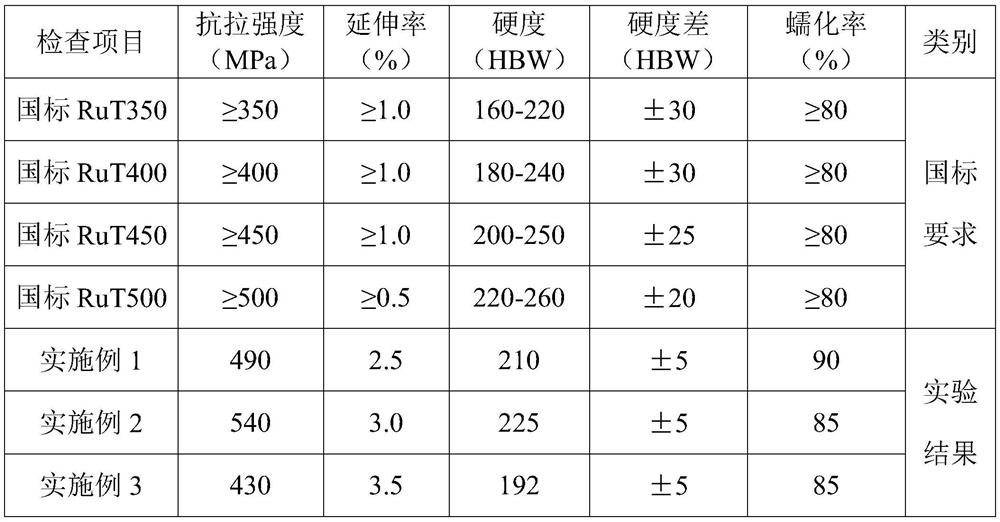

[0030] The matrix structure in silicon solid solution strengthened ferritic vermicular graphite cast iron includes ferrite and pearlite, the mass fraction of ferrite is 95%, and the mass fraction of pearlite is 5%. The cast iron contains the following chemical components in mass fractions: carbon 3.1%, silicon 4.2%, sulfur 0.011%, magnesium 0.012%, rare earth 0.028%, and the balance is iron and unavoidable trace elements; wherein, carbon equivalent = 4.5%, carbon Equivalent = mass percent of carbon + mass percent of silicon / 3. The carbon used in this embodiment includes vermicular graphite with a mass fraction of 85% and spherical graphite with a mass fraction of 15%. The vermicularity of the vermicular graphite cast iron in this embodiment is 90%, the tensile strength is 490MPa, the hardness is 210HBW, and the elongation is 2.5%.

Embodiment 2

[0032]The matrix structure in silicon solid solution strengthened ferritic vermicular graphite cast iron includes ferrite and pearlite, the mass fraction of ferrite is 96%, and the mass fraction of pearlite is 4%. The cast iron contains the following chemical components in mass fractions: 2.9% carbon, 4.8% silicon, 0.012% sulfur, 0.013% magnesium, 0.030% rare earth, and the balance is iron and unavoidable trace elements; wherein, carbon equivalent = 4.5%, so The above-mentioned carbon equivalent=mass percentage of carbon+mass percentage of silicon / 3. The carbon used in this embodiment includes vermicular graphite with a mass fraction of 87% and spherical graphite with a mass fraction of 13%. The vermicularity of the vermicular graphite cast iron in this embodiment is 85%, the tensile strength is 540MPa, the hardness is 225HBW, and the elongation is 3.0%.

Embodiment 3

[0034] The matrix structure in silicon solid solution strengthened ferritic vermicular graphite cast iron includes ferrite and pearlite, the mass fraction of ferrite is 96%, and the mass fraction of pearlite is 4%. The cast iron contains the following chemical components in mass fractions: 3.3% carbon, 4.0% silicon, 0.012% sulfur, 0.013% magnesium, 0.030% rare earth, and the balance is iron and unavoidable trace elements; wherein, carbon equivalent = 4.6%, so The above-mentioned carbon equivalent=mass percentage of carbon+mass percentage of silicon / 3. The carbon used in this embodiment includes vermicular graphite with a mass fraction of 95% and spherical graphite with a mass fraction of 5%. The vermicularity of the vermicular graphite cast iron in this embodiment is 85%, the tensile strength is 430MPa, the hardness is 192HBW, and the elongation is 3.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com