Screen for house construction

A sieve and house technology, applied in the field of sieves for house construction, can solve the problems of low labor efficiency, easily damaged screen, high cost, etc., and achieve the effects of not easy to damage the screen, good screening effect, and long screening distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

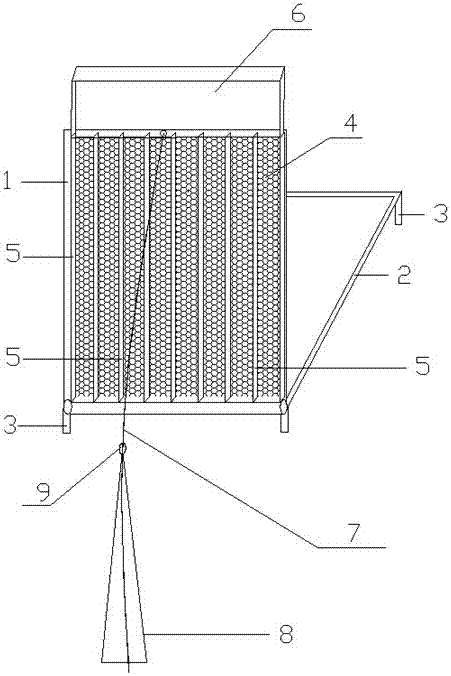

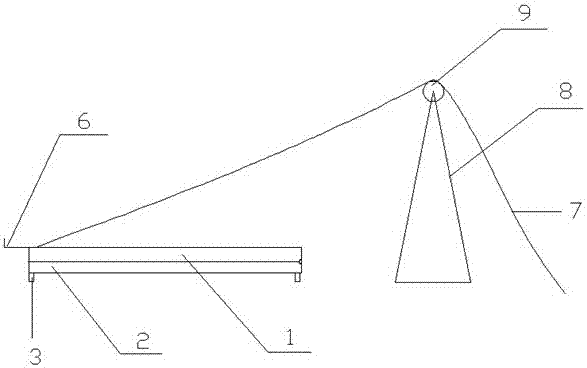

[0009] The present invention will be further described below in conjunction with the accompanying drawings, but not as a limitation of the present invention. This embodiment comprises an upper frame 1 and a lower frame 2, the upper frame 1 and the lower frame 2 are equal in size and are all rectangular, one end between the upper frame 1 and the lower frame 2 is connected by a rotating shaft, and the upper frame 1 can rotate around the rotating shaft. Four corners of the lower frame 2 are provided with pillars 3, and the height of the pillars 3 is 30cm. A screen 4 is provided on the upper frame 1, and a baffle 5 is provided on the left and right borders of the screen 4. A baffle 5 is arranged on the screen 4 every 20 cm. The length of the baffle 5 is equal to that of the screen 4, and the height of the baffle 5 is Be 10cm, these baffles 5 divide screen cloth 4 into a road, as figure 1 shown. The front end of the upper frame 1 is integrally connected with a sand container 6, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com