Full-automatic garbage classification treatment separation line and process

A graded processing, fully automatic technology, applied in chemical instruments and methods, solid waste removal, transportation and packaging, etc., can solve the problems of complex urban waste composition, abandonment of recyclables, waste of recyclable resources, etc., to achieve fast and effective The effect of comprehensive inspection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

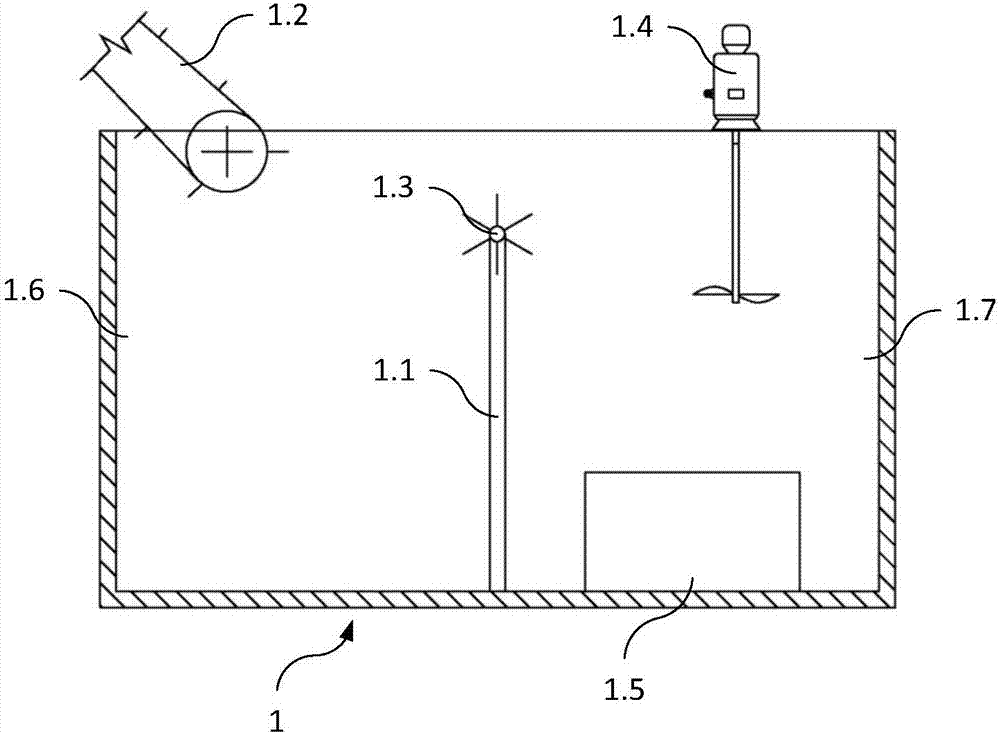

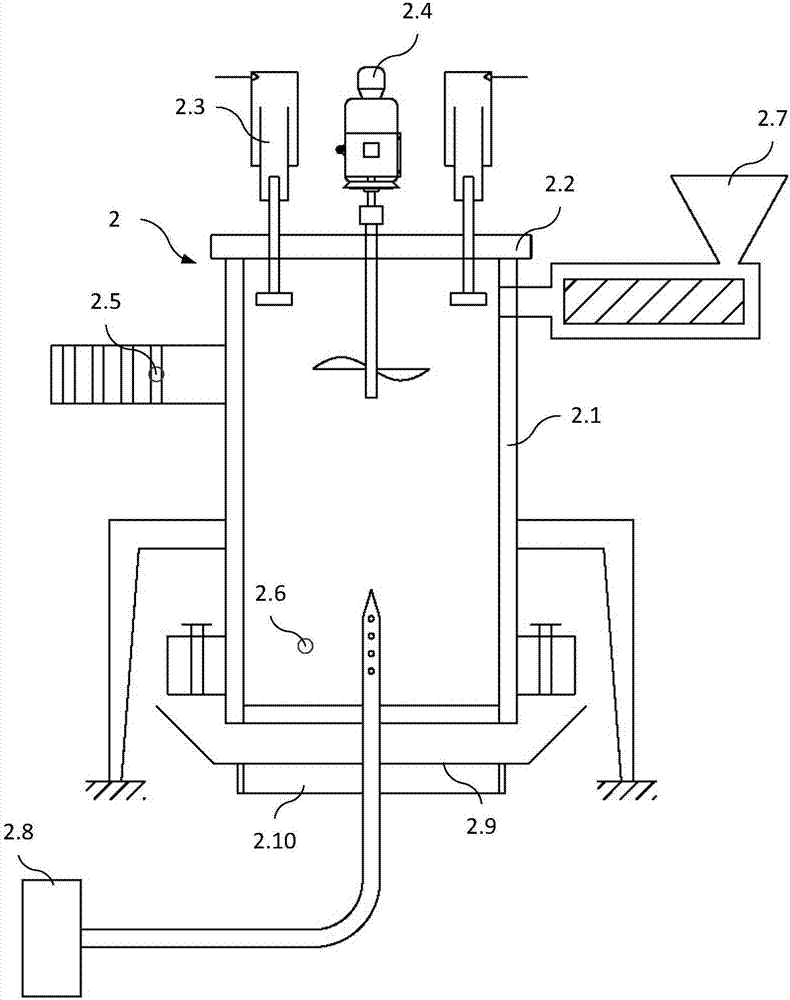

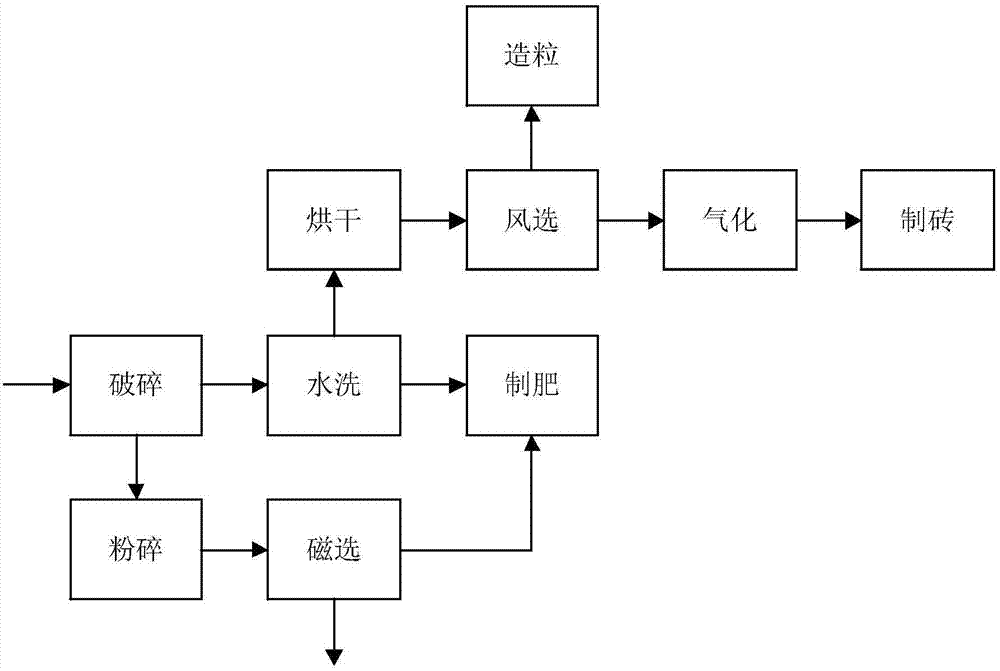

[0039] Such as Figures 1 to 3 As shown, a fully automatic garbage classification and sorting line, including: crusher, washing tank 1, dryer, pulverizer, magnetic separator, wind separator, gasifier 2, granulator, brick making machine and fertilizer machines.

[0040] The function of the crusher is to initially crush the garbage, forming larger materials (such as paper, plastic, fabric and other objects that are not easy to be physically broken) and smaller materials (such as metal objects, glass and other materials that are easily broken by physics) ), so the crusher has two outlets, one of which outputs materials with a smaller volume and is sequentially input into the pulverizer and magnet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com