Tensioning device of embedded scraper conveyer

A technology of buried scraper conveyor and tensioning device, which is used in conveyors, transportation and packaging, etc., can solve the problems of difficult rotation of the tensioning screw, wear of the screw, complicated structure, etc. turn easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

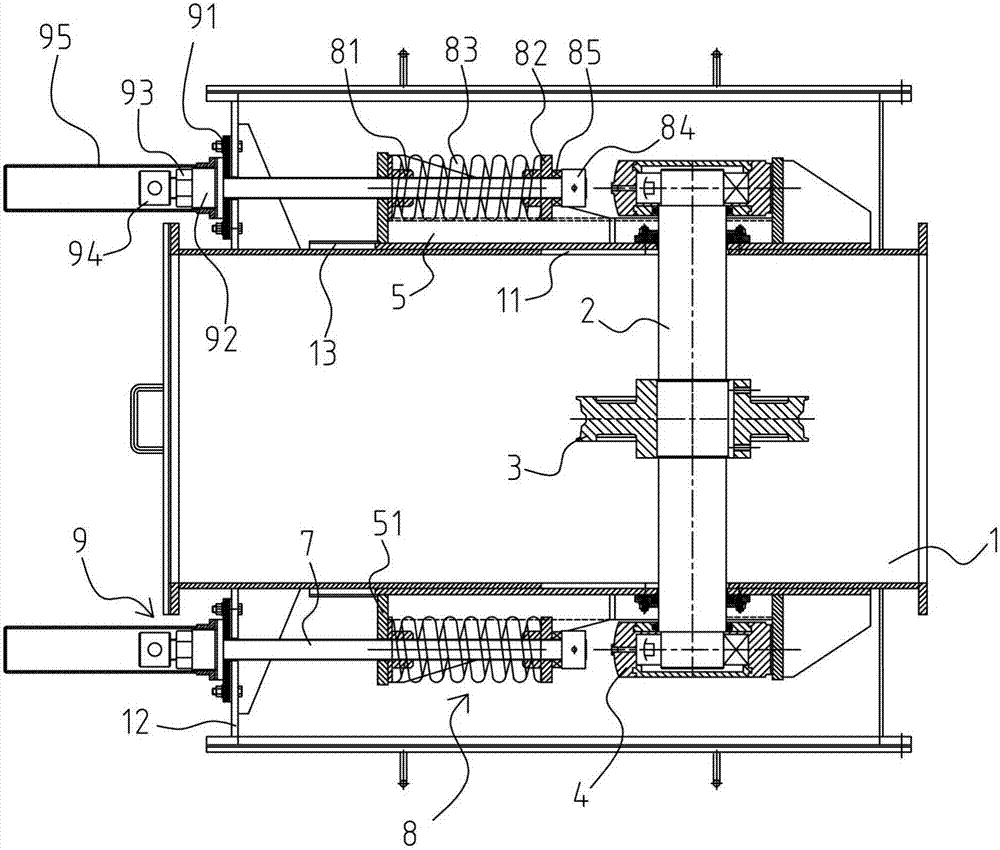

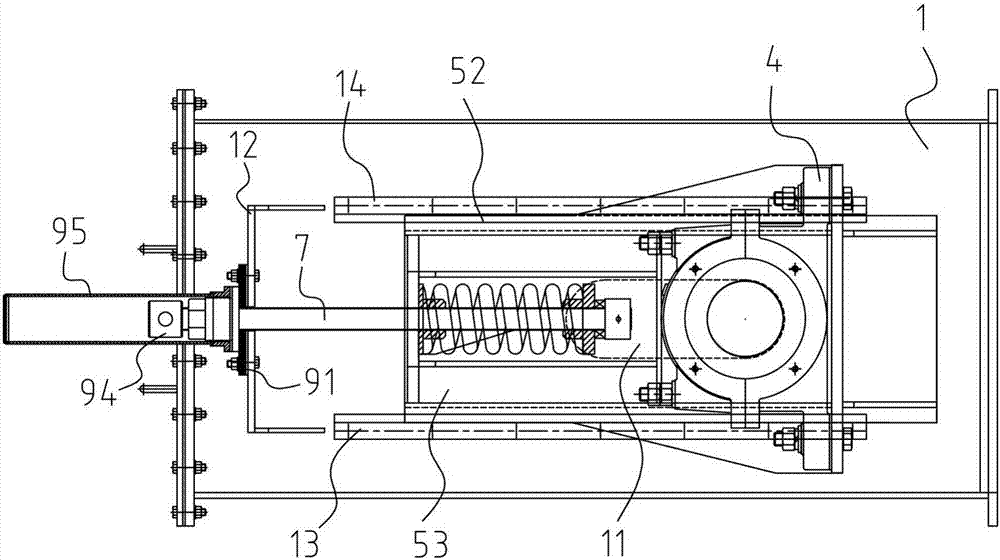

[0014] Such as figure 1 and 2 Shown: a tensioning device for a buried scraper conveyor, including two symmetrically opened waist-shaped holes 11 on two opposite outer walls of the casing 1, one is placed in the waist-shaped hole 11 and can be moved along the axis of the waist-shaped hole 11 The rotating shaft 2 moving linearly, a sprocket 3 installed in the middle of the rotating shaft 2, two shaft seats 4 respectively axially connected to the two ends of the rotating shaft 2, a sliding frame 5 fixedly connected to each shaft seat 4, two groups of symmetrically fixed The guide plate group on the two opposite outer walls of the casing 1 and the tensile assembly connected to the sliding frame 5 at one end;

[0015] The guide plate group includes an upper guide plate 14 and a lower guide plate 13 fixed on the outer wall of the casing 1 symmetrically with the axis of the waist row hole as the line of symmetry;

[0016] Sliding frame 5 comprises panel 53, is provided with guide r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com