Coupling hoist achieving automatic cable take-up and pay-off for unmanned ship

An automatic retractable and unmanned ship technology, which is applied in the direction of hoisting device and clockwork mechanism, can solve the problems of heavy installation workload, prolonging the pulling out time, hindering the pulling out of cables, etc., and reducing the equipment space Utilization rate, overcoming the difficulty of processing, and reducing the effect of installation difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to make those skilled in the art better understand the technical solutions of the present invention, the present invention will be further described in detail below with reference to specific embodiments. The embodiments described below are exemplary, only for explaining the present invention, and should not be construed as limiting the present invention. If no specific technique or condition is indicated in the examples, the technique or condition described in the literature in the field or the product specification is used.

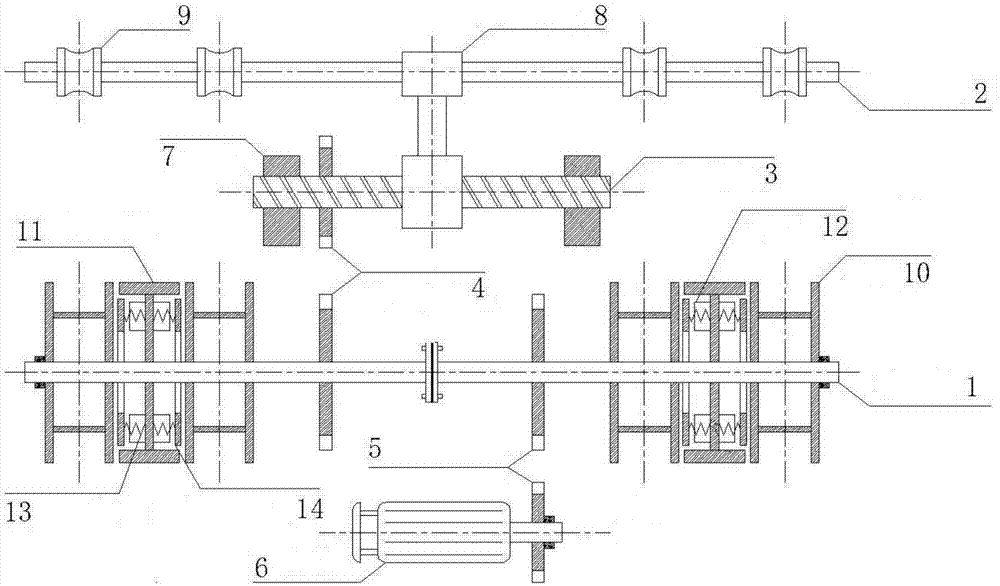

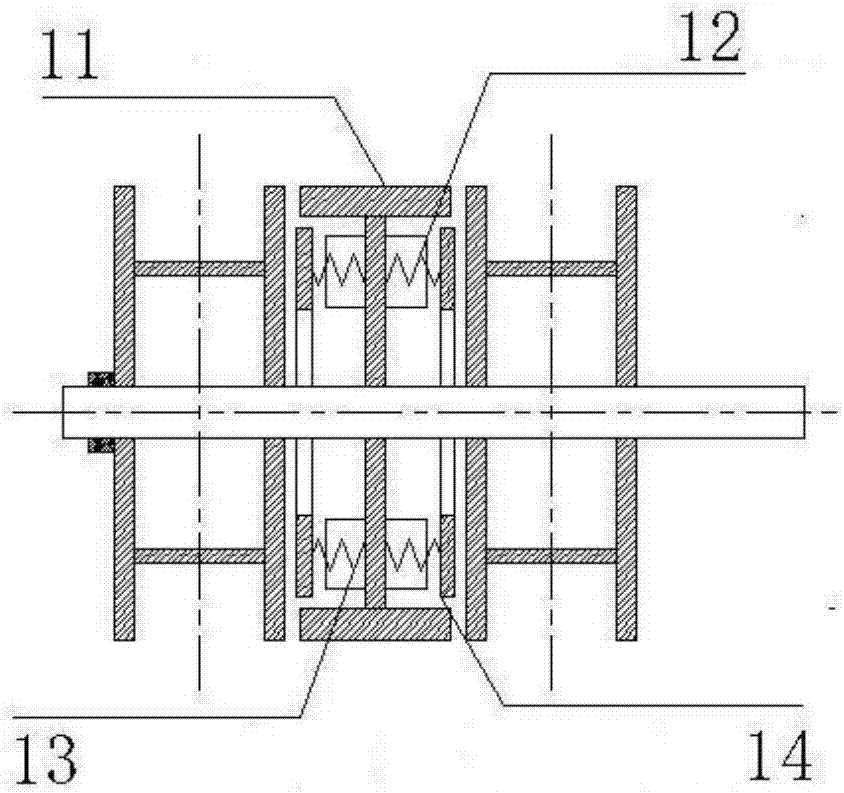

[0038]According to the embodiment of the present invention, the present invention provides a coupling hoist for automatically retracting and unwinding cables for unmanned ships, and designs a load power supply relay contact switch module and a reciprocating automatic cable pulley driven by a sprocket, which solves the problem of existing The hoist needs to pull out the power cord from the dragging cable for the use of the electrical equi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com