Supporting and adjusting device for titanium sponge distillator

A technology of adjusting device and distillation tank, which is applied in the field of sponge titanium, can solve the problems of high frictional resistance, affecting production efficiency, shortening service life, etc., and achieves the goal of eliminating thermal expansion and contraction, reducing the time for distillation and improving service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

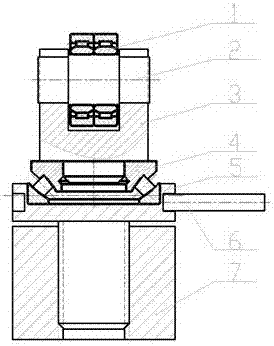

[0015] Three devices pre-adjusted to the predicted heights are distributed and installed on the lower surface of the flange of the retort, and the specific position must ensure that the retort is stable and cannot interfere with other components.

[0016] Adjust the rolling direction of the support bearing 1 to be consistent with the expansion and contraction direction of the connecting pipeline.

[0017] By adjusting the adjustment handle 6 to rotate the adjustment support 5, the adjustment of the height of the retort can be realized, which is convenient for the butt joint installation of the horizontal pipeline.

[0018] After the channels are aligned, the pipes are welded to complete the piping connection for the distillation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com