Trowelling machine

A technology of troweling machine and gear motor, which is applied in the field of troweling machine, can solve the problems of machine overweight, cement failure, machine falling on wet cement, etc., and achieve the effect of saving time, improving work efficiency and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the technical means and creative features of the present invention simpler, clearer and easier to understand, the present invention is now further described by the following embodiments.

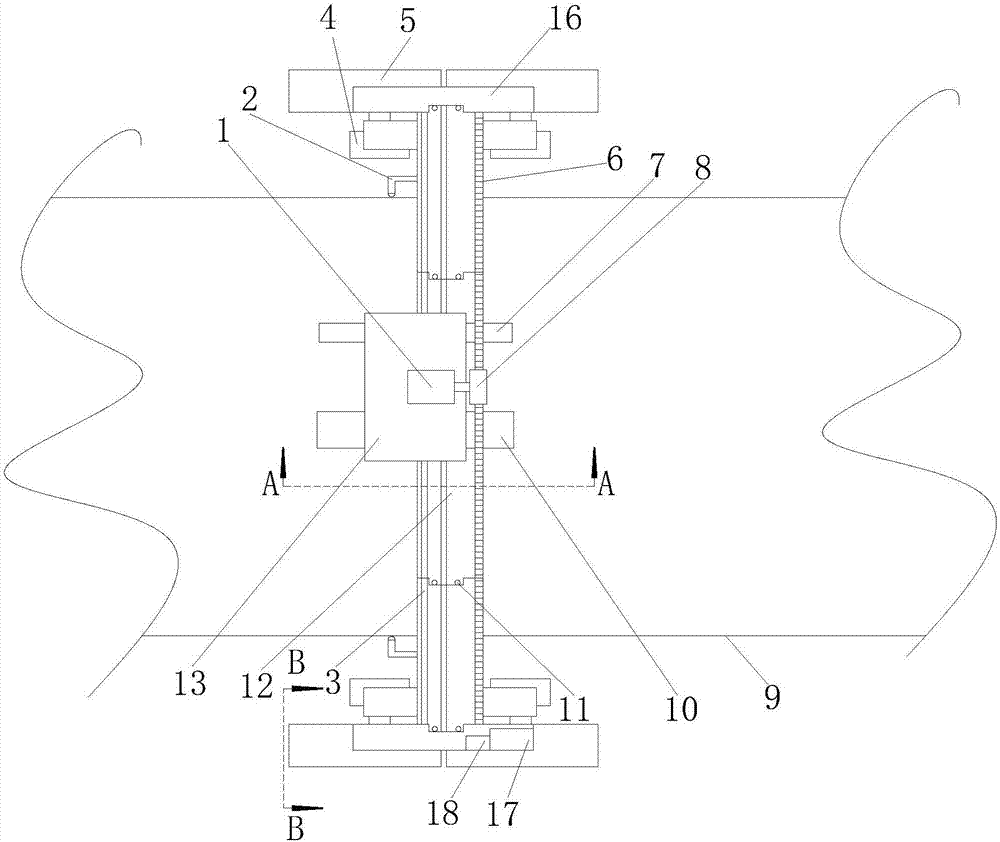

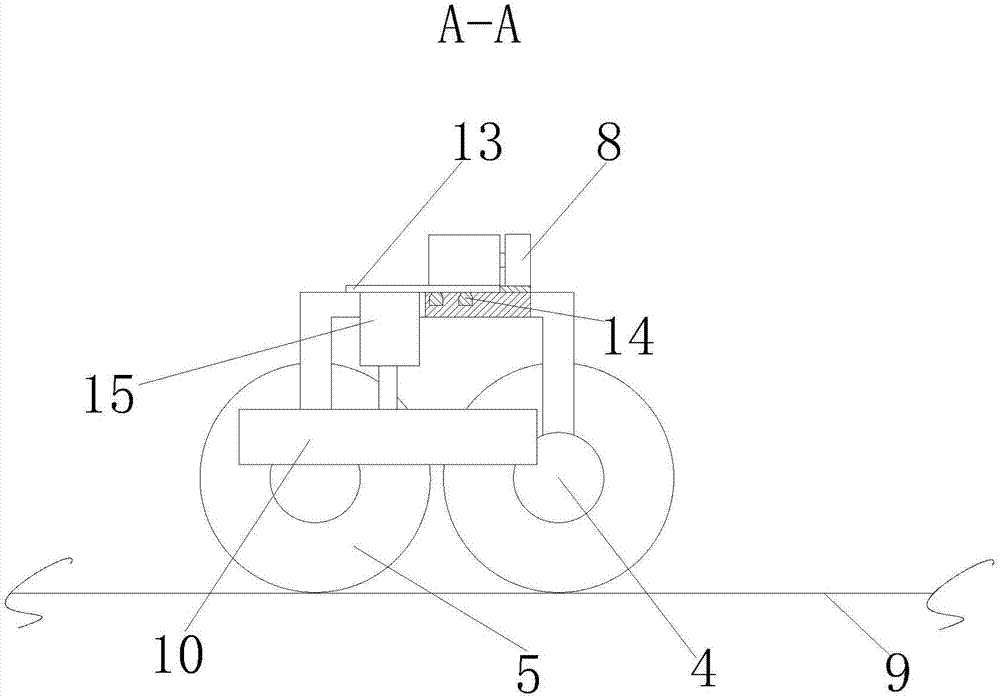

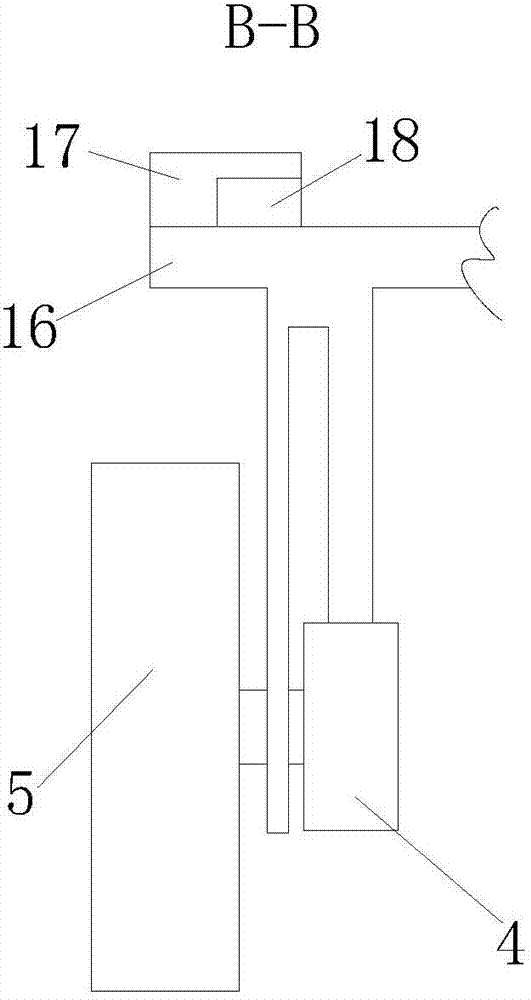

[0021] Such as Figure 1 to Figure 3 As shown, a troweling machine includes shelves 16 distributed on both sides of the road 9, rollers 5 under the shelves 16, and several connecting plates 12 that are spliced end to end and formed as tracks are connected between the two shelves 16. , a support platform 13 is slidably installed on the track, the upper end of the support platform 13 is connected with a traverse mechanism that drives the support platform 13 to slide on the track, and the lower end of the support platform 13 is connected with a smoothing mechanism, which also includes a mounting Any one shelf 16 in the two shelves 16 is used to limit the travel switch device of support table 13 movement range.

[0022] The traverse mechanism is at the upper end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com