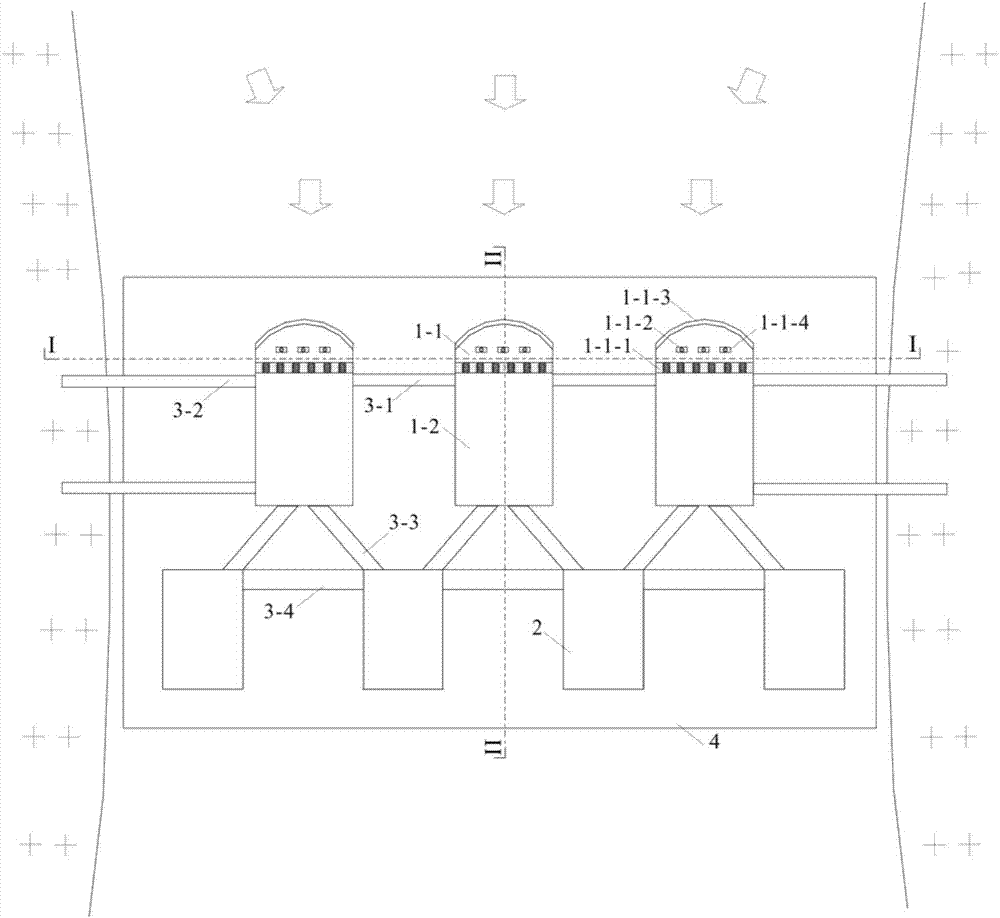

Especially-big high-altitude debris flow self-resetting energy-consuming blocking structure and implement method

A mudslide and self-resetting technology, which is applied in the direction of construction and protective equipment, can solve the problems of destroying downstream houses, blocking downstream rivers, hazards, etc., to reduce the damage of downstream sites, increase anti-collision reset capabilities, and have strong operability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

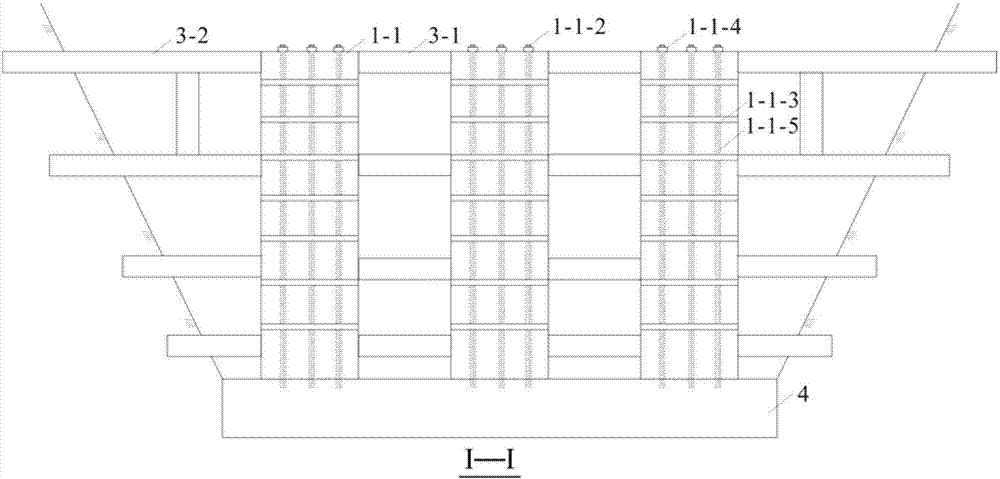

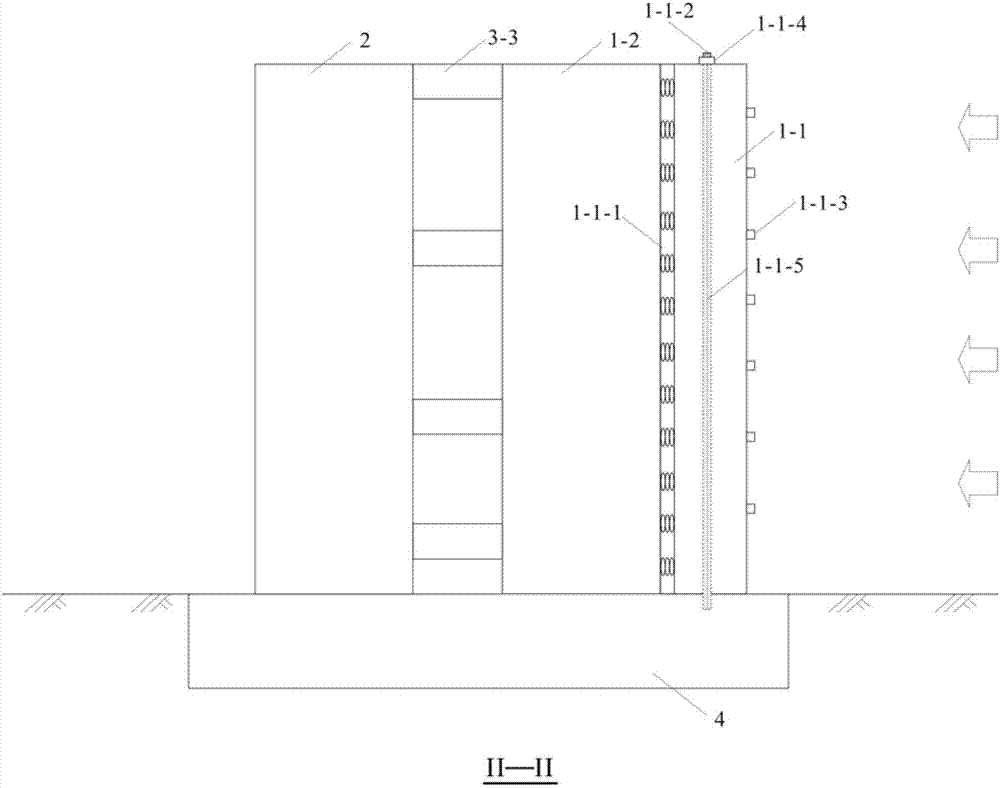

Method used

Image

Examples

Embodiment

[0035] Example: Conditions in the construction area: The height difference of the debris flow channel is 2.5km, and the channel is 6km long. There are a large number of geological disasters such as collapses and landslides on both sides of the river, and the flow rate has historically been as high as 2000m 3 / s, its solid sources are abundant, and the volume of block stones can reach up to 500m 3, The impact of the block stone is huge. The specific construction steps are as follows. The first step: measuring and positioning. According to the design requirements, the measurement and setting out are generally carried out at the bend and closing section of the trench to determine the position of the sheet raft foundation and piles; the second step: construction of the reinforced concrete sheet raft foundation. Excavate to the design depth, lay out the formwork, place the reinforcement cage, and pour the raft foundation; the third step: construct the reinforced concrete pile str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com