Metering valve state detection method and metering valve state detection system based on multi-signal fusion

A state detection and signal detection technology, applied in the direction of valve devices, engine components, mechanical equipment, etc., can solve problems such as failure to obtain fault information, failure to continue detection and judgment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

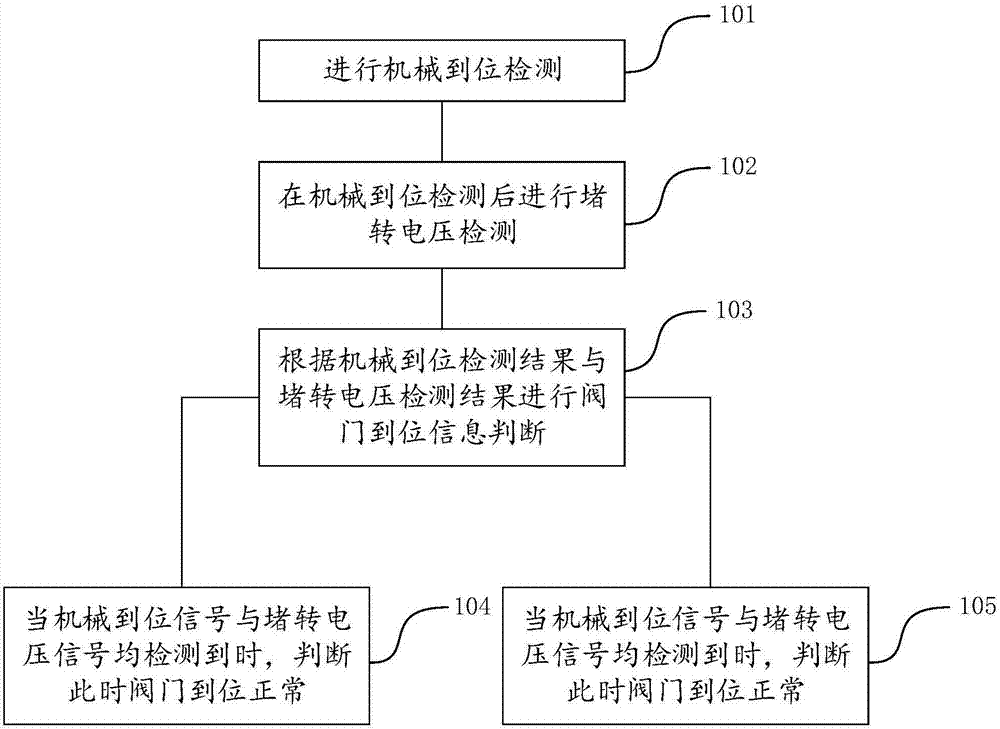

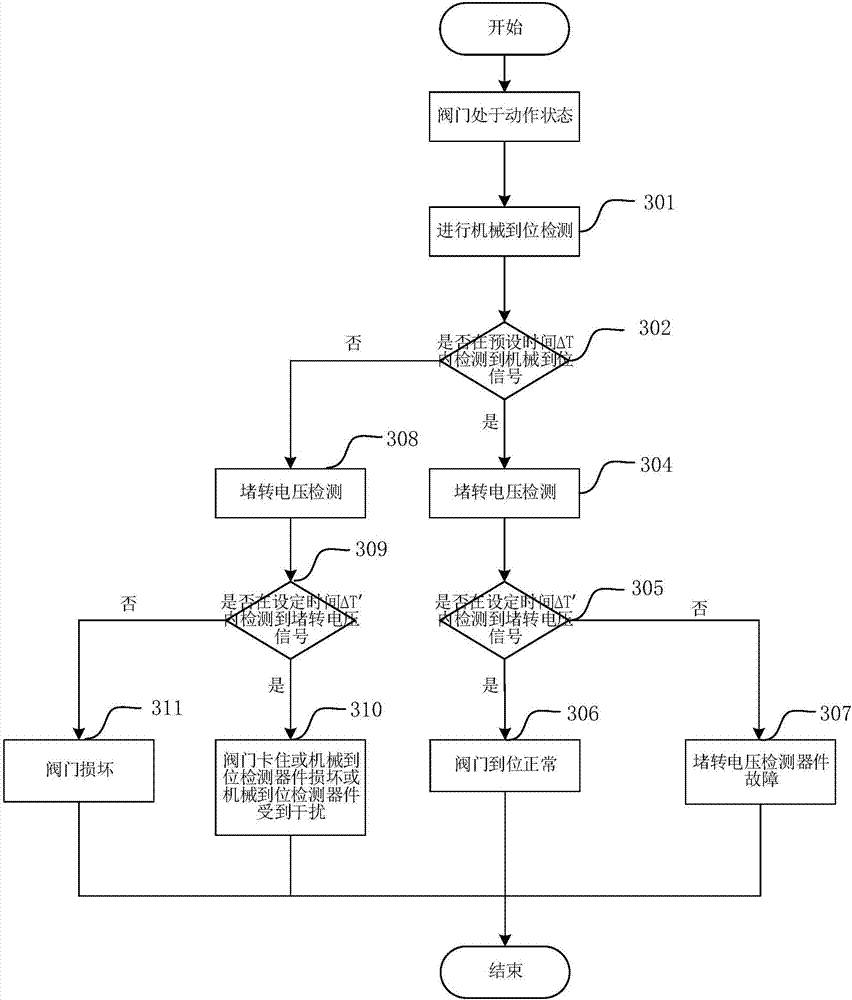

[0057] The present invention proposes a meter valve state detection method based on multi-signal fusion. When the valve is in the action state, it executes as figure 1 Steps shown:

[0058] Step 101: Perform mechanical in-position detection;

[0059] Step 102: Perform locked-rotor voltage detection after the mechanical in-position detection;

[0060] Step 103: Judging the valve in-position information according to the mechanical in-position detection result and the locked-rotor voltage detection result;

[0061] Step 104: When both the mechanical in-position signal and the locked-rotor voltage signal are detected, it is judged that the valve is in place at this time and is normal;

[0062] Step 105: When any one of the mechanical in-position signal and the locked-rotor voltage signal is not detected, judge the valve in-position fault information.

[0063] In the above-mentioned meter valve state detection method based on multi-signal fusion, the mechanical in-position detec...

Embodiment 2

[0097] The present invention proposes a meter valve state detection system based on multi-signal fusion, such as Figure 4 As shown, it includes the control unit, the mechanical in-position detection module for detecting the mechanical in-position detection module, the valve drive module for controlling the valve switch and the voltage in-position detection module for detecting the locked-rotor voltage. The control unit is connected with the mechanical in-position detection module to control The unit is connected with the voltage in-position detection module, and the control unit is connected with the valve driving module to control the valve driving module.

[0098] In the meter valve state detection system based on multi-signal fusion, the control unit can obtain the mechanical in-position detection result detected by the mechanical in-position detection module and the locked-rotor voltage detection result detected by the voltage in-position detection module, and then can acc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com