Self-learning automatic noise reduction system and method of kitchen ventilator

A noise reduction system and self-learning technology, applied in the fields of oil fume removal, heating method, household heating, etc., can solve the problems of complex model and algorithm, large difference in noise reduction effect, and poor effect, and achieve the effect of preventing interference.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

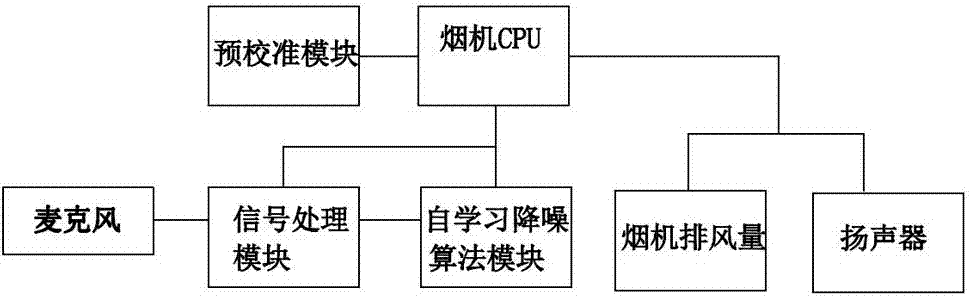

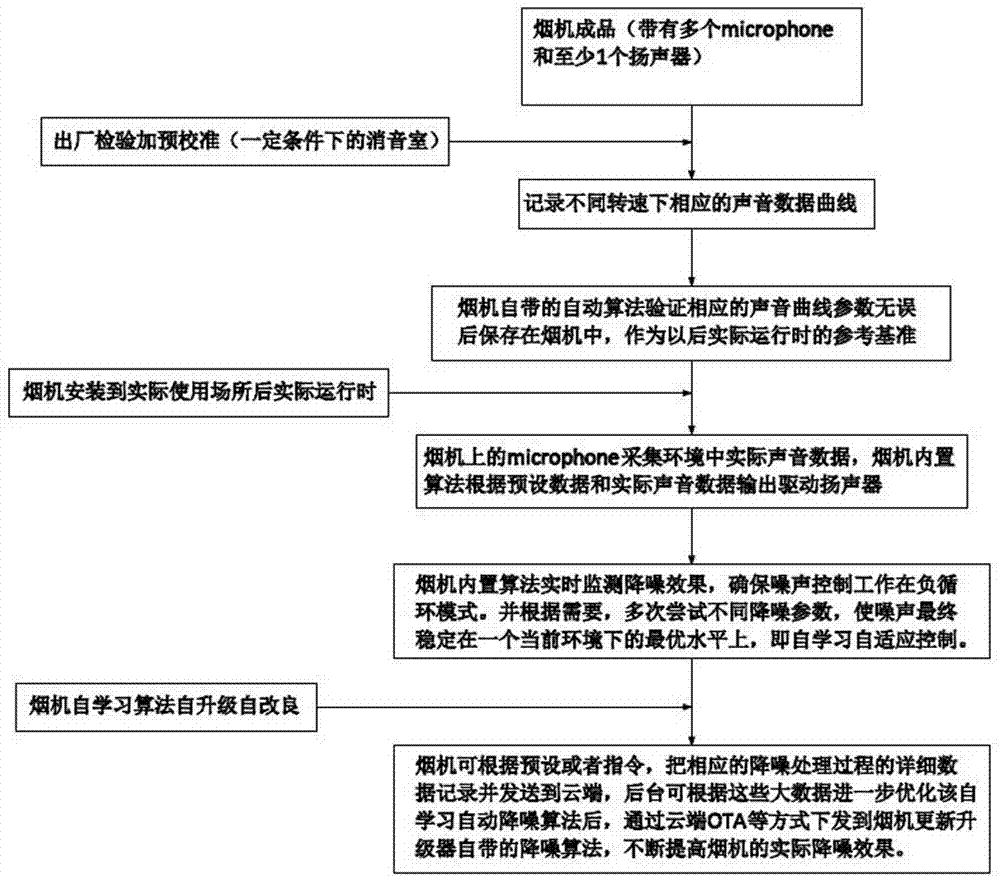

[0027] Embodiment 1: as figure 1 As shown, the range hood self-learning automatic noise reduction system mainly includes a range hood, on which a microphone and a speaker are arranged, and the CPU of the range hood is electrically connected to the signal processing module, the self-learning noise reduction algorithm module and the pre-calibration module respectively. ,in,

[0028] The microphone is used to collect the data of hood noise and environmental noise;

[0029] The signal processing module is used for signal processing the noise data collected by the microphone;

[0030] Pre-calibration module: At different pre-set speeds, the hood collects a series of sound curve parameters and records them as the preset benchmark data for actual on-site operation in the future;

[0031] The self-learning noise reduction algorithm module generates corresponding sound waveforms according to the preset benchmark data and combined with the measured noise data of hood noise and environ...

Embodiment 2

[0033] Embodiment 2: On the basis of Embodiment 1, the hood adopts a frequency conversion hood or a multi-speed speed-regulating motor to achieve the purpose of speed regulation at multiple speeds, and can achieve automatic noise reduction under various speeds the goal of.

Embodiment 3

[0034] Embodiment 3: On the basis of Embodiments 1 and 2, at least two microphones and one loudspeaker are provided, and the microphones and loudspeakers are arranged in multi-points by area. Set it in a place with high noise, and also set it in a place with relatively low noise. It can collect noise signals of different decibels, which is conducive to optimizing and upgrading the self-learning automatic noise reduction algorithm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com