Integrated measuring connector device for sealed equipment

A technology of sealing equipment and joint devices, which is applied in the direction of measuring devices, mechanical equipment, heat exchange equipment, etc., can solve the problems of inconvenient debugging, operation and maintenance, increased workload, and influence on heat preservation effect, etc., and achieves ingenious design structure, reduced The effect of low installation workload and low cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention is further illustrated below by means of examples, but the present invention is not limited to the scope of the examples.

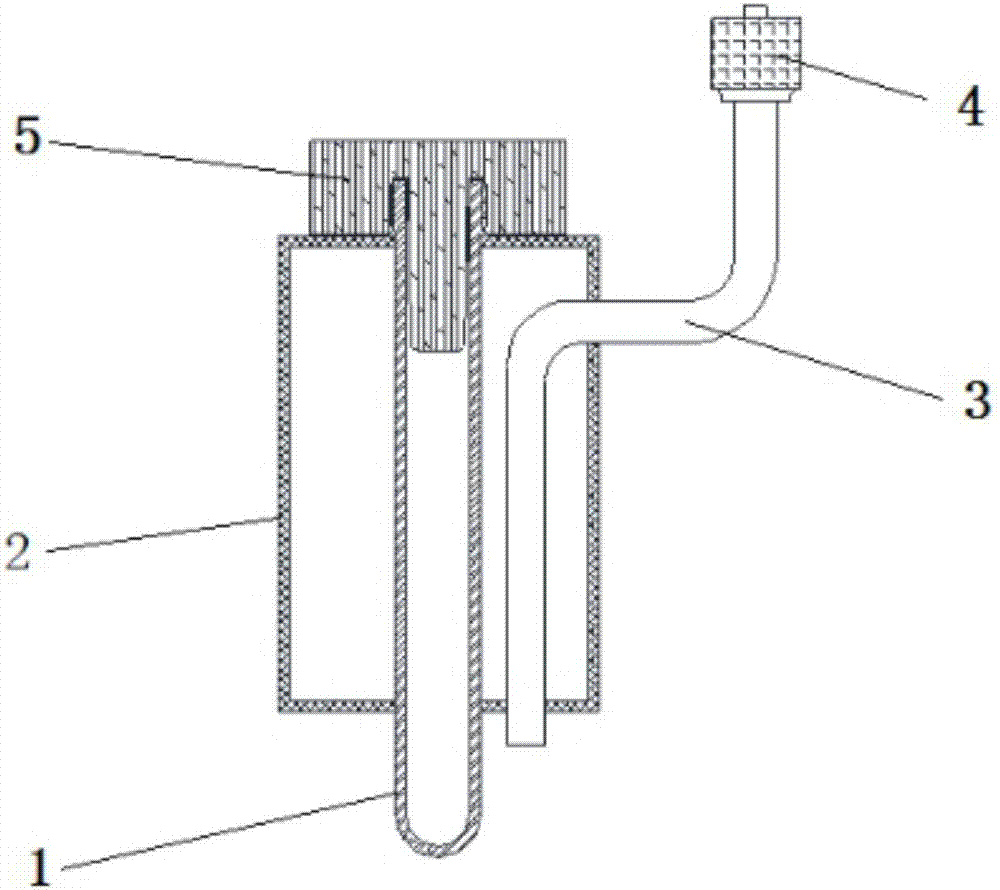

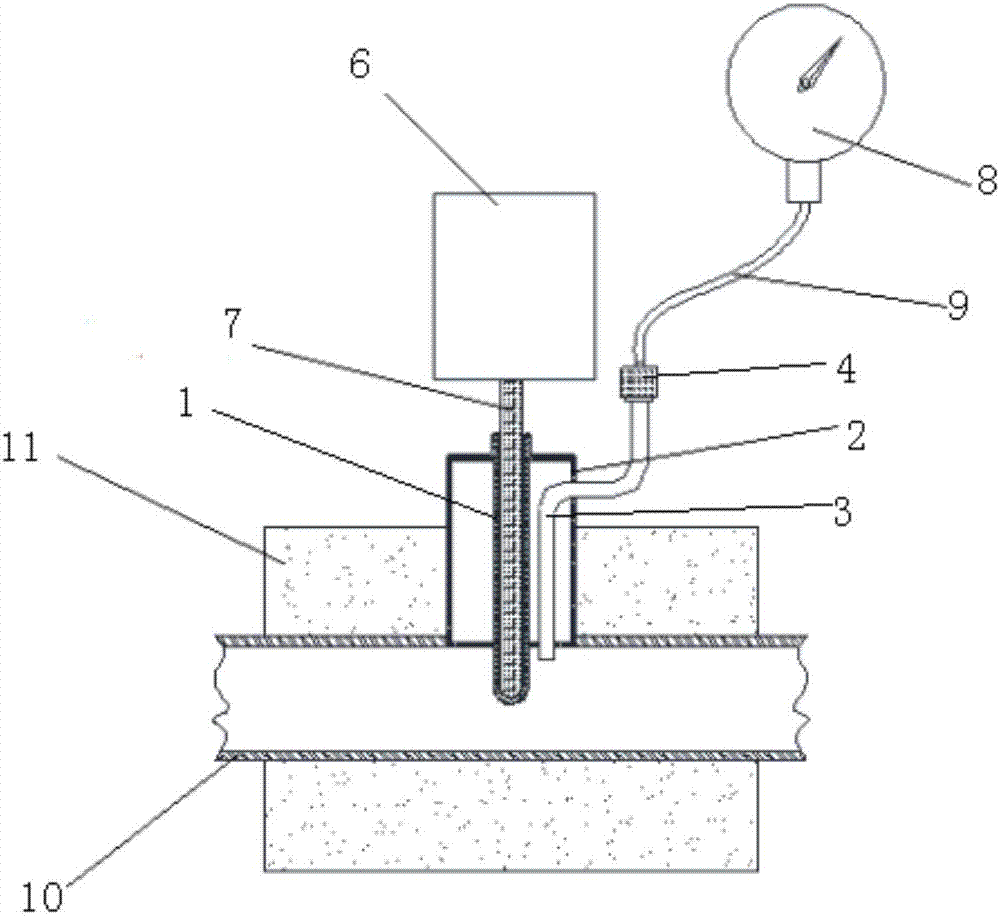

[0018] See figure 1 and figure 2 , the present invention is an integrated measuring joint device for sealing equipment, comprising a hollow heat-insulating shell and several measuring tubes, the lower end surface of the hollow heat-insulating shell is closely arranged on the outer surface of the sealing equipment, and the sealing setting can be made by such as figure 2 The shown fluid pipeline 10 and insulation layer 11 are composed. The measuring tube is installed on the hollow insulating shell, one end of the measuring tube passes through the lower end surface of the hollow insulating shell and the outer surface of the sealing device to contact the measured medium in the sealing device, and the other end of the measuring tube passes through the hollow The top or side of the insulated housing is connected to the measuring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com