Anti-icing tracking resistance ADSS optical cable and manufacturing technology

A technology of resistance to electrical tracking and anti-icing, which is applied in the field of ADSS optical cables, can solve the problems of decreased leakage resistance of optical cables, increase the load-bearing weight of optical cables, and shorten the service life of optical cables, so as to enhance the bonding effect, ensure integrity and service life , Improve the effect of electric tracking resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

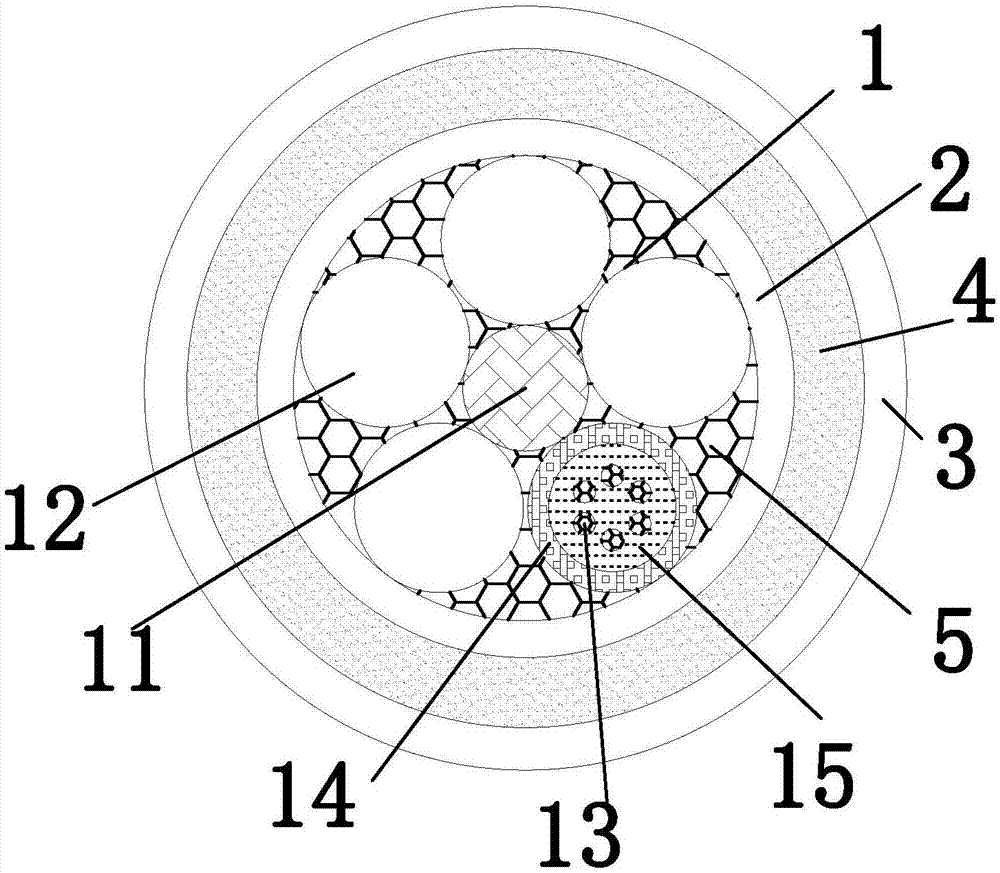

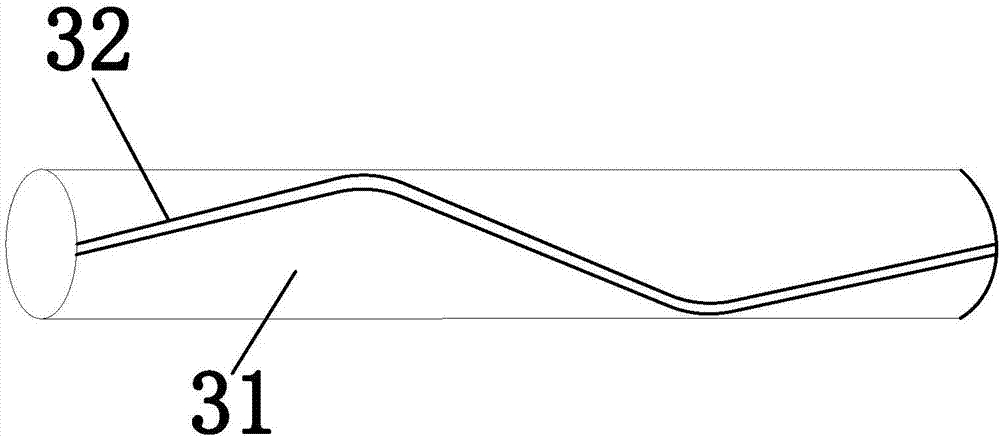

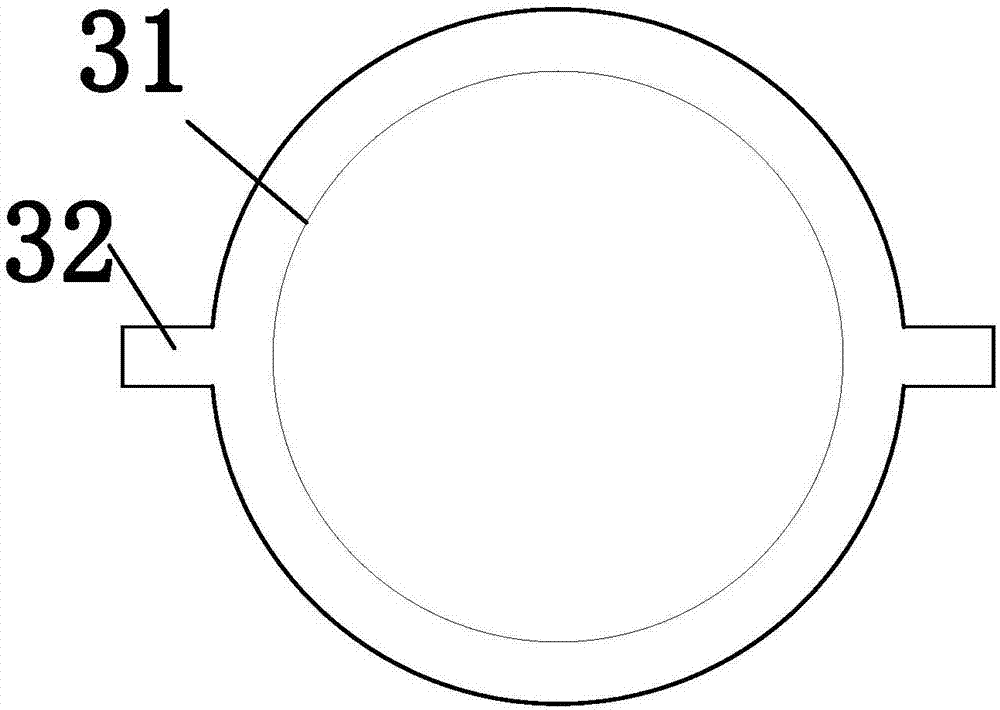

[0022] Example. An anti-icing anti-tracking ADSS optical cable, constituted as follows Figure 1 to Figure 3 As shown, including the cable core 1, the inner sheath 2 and the outer sheath 3 are arranged on the outside of the cable core 1 in turn, and the tension-resistant layer 4 is arranged between the inner sheath 2 and the outer sheath 3, and the cable core 1 and the inner sheath 2 is provided with a first water-blocking filler 5; the outer sheath 3 includes an outer sheath main body 31, and the outer surface of the outer sheath main body 31 is provided with alternating ribs 32.

[0023] The tension-resistant layer 4 includes aramid yarn and basalt fiber; the aramid yarn and basalt fiber are evenly twisted on the outer surface of the inner sheath at a ratio of 1:6-3:4.

[0024] The tension-resis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com