Plate-making method and system for automatically adjusting shrinkage

An automatic adjustment and reduction technology, which is applied to the photoengraving process of the pattern surface, the exposure device of the photoengraving process, the microlithography exposure equipment, etc., can solve the problems of reducing the production efficiency and increasing the production time, so as to improve the production efficiency. , Reduce the difficulty and enhance the printing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

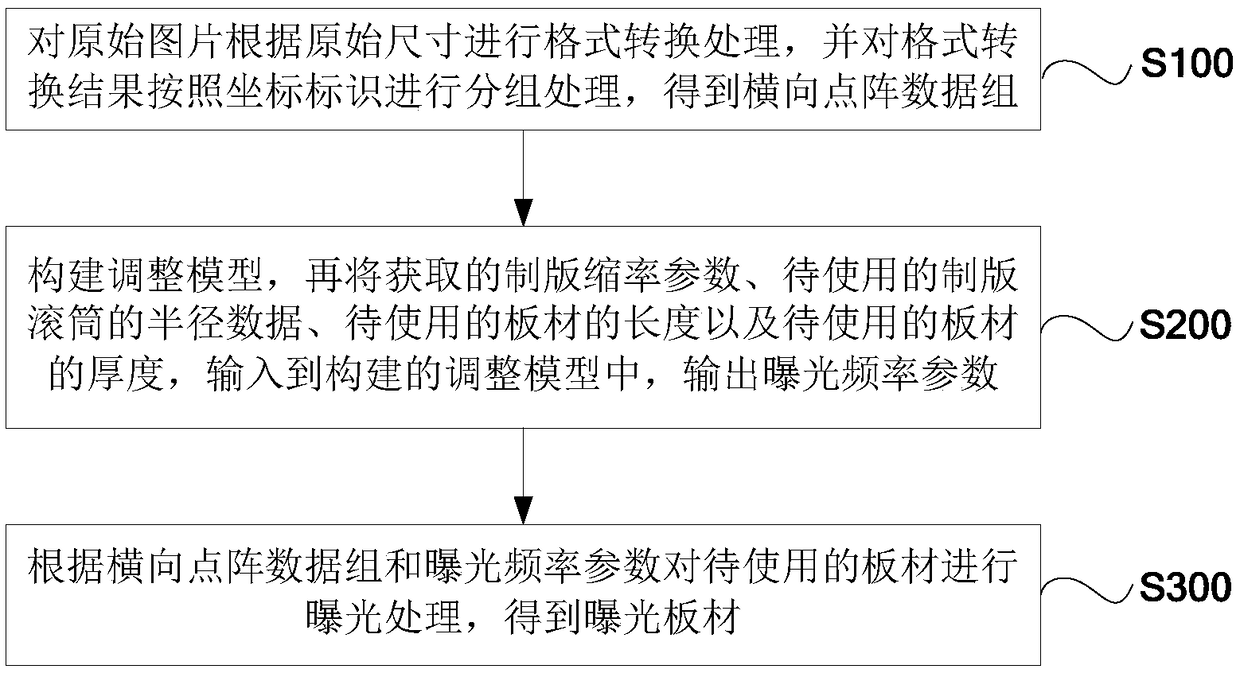

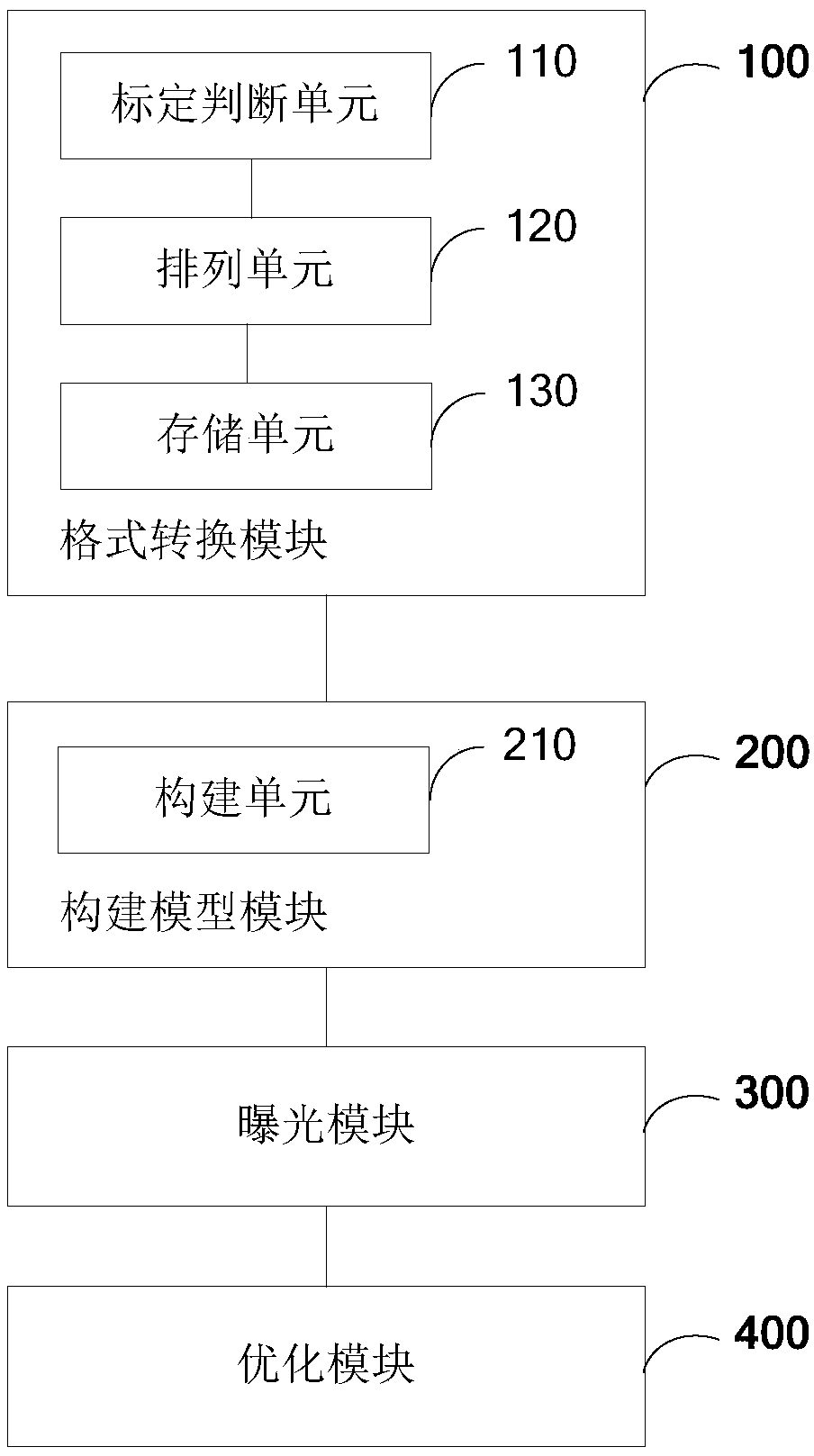

Method used

Image

Examples

Embodiment Construction

[0058] The above and other technical features and advantages of the present invention will be clearly and completely described below in conjunction with the accompanying drawings. Apparently, the described embodiments are only some of the embodiments of the present invention, not all of them.

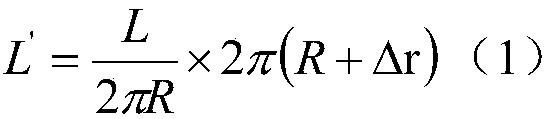

[0059] Existing flexible sheets are all laser-irradiated sheets made of resin as raw material, and the resin has special stretchability. During production, the user needs to attach the plate flatly to the side of a horizontally placed cylindrical roller, and when the roller rotates with the adhered plate around the center line of the circle, the laser performs continuous processing on the plate at a constant frequency. Exposure, the cylinder in this process is called plate cylinder. After the exposed plate is specially treated, it is flatly attached to another cylinder with a smaller center diameter. When the cylinder also rotates around the center line as the axis, color printing can b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com