Prediction method of carbide blade chemical-mechanical polishing surface roughness

A cemented carbide insert and surface roughness technology, applied in the field of mechanical processing technology, can solve problems such as low production efficiency and unstable processing process, and achieve the effects of improving accuracy, improving global optimization capabilities, and reducing production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments, but the protection scope of the present invention is not limited to the following embodiments.

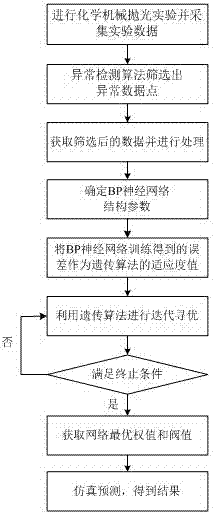

[0052] figure 1 It is a flow chart of the chemical mechanical polishing cemented carbide blade surface roughness prediction model of the present invention, specifically comprising the following steps:

[0053] Step 1. Design the experimental parameters and experimental schemes of chemical mechanical polishing carbide inserts, and the collection of experimental data;

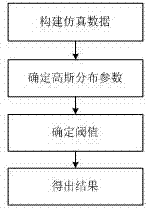

[0054] Step 2. Using an abnormality detection algorithm based on a Gaussian function to preprocess the experimental sample data;

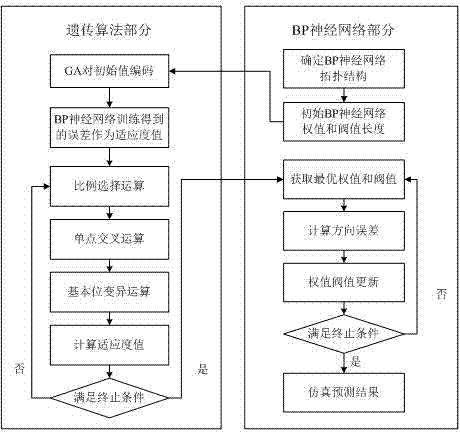

[0055] Step 3: Establish a genetic algorithm to optimize the prediction model of the BP neural network, and use the preprocessed experimental sample data to learn and train the prediction model, so as to obtain the surface roughness prediction model of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com