Flexible workshop task scheduling optimization method based on hybrid algorithm of DE and L-BFGS-B

A technology of L-BFGS-B and task scheduling, which is applied in the direction of chaos model, complex mathematical operation, nonlinear system model, etc., and can solve problems such as slow convergence speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

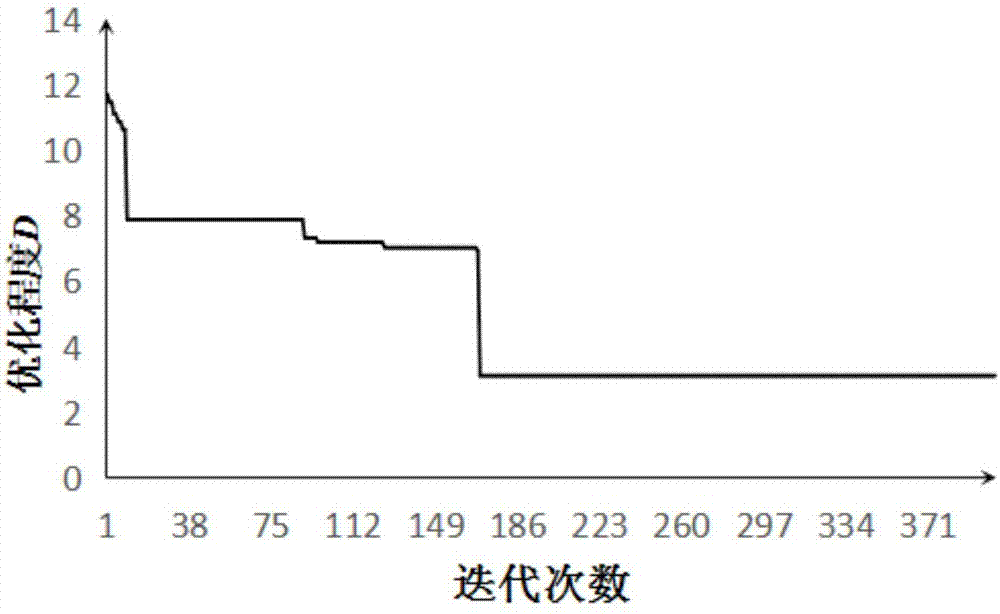

[0071] This embodiment is described based on the production scheduling problem of a flexible workshop of an aerospace enterprise.

[0072] Table 1 below shows the weekly planned production task data of the flexible workshop of an aerospace enterprise. At present, there are 37 operators in the workshop and 20 operating equipment, and the daily production capacity of each equipment is 12 hours. After decomposing each component based on the process information table, there are 90 operating procedures and 270 decision variables.

[0073] Table 1 Weekly planned production tasks of a flexible workshop in an aerospace enterprise

[0074]

[0075]

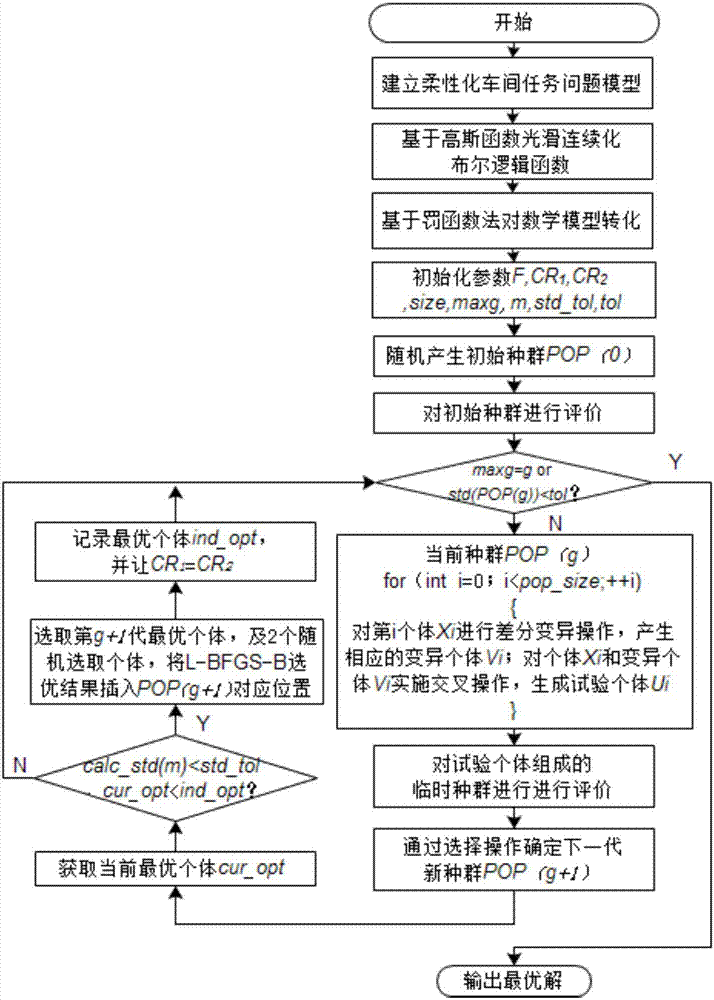

[0076] Such as figure 1 As shown, for this example, the scheduling method based on the DE-LBFGSB algorithm includes the following steps:

[0077] Step 1: Establish a flexible workshop task scheduling problem model;

[0078] The mathematical programming model of this problem is: the optimization objective is to minimize the delay,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com