Robust single machine scheduling method based on interval uncertainty

A robust stand-alone, scheduling method technology for control/regulation systems, instruments, adaptive control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0070] The present invention proposes a robust single-machine scheduling method based on interval uncertainty, which is described in further detail below in conjunction with specific embodiments.

[0071] The present invention proposes a robust single-machine scheduling method based on interval uncertainty, including the following steps:

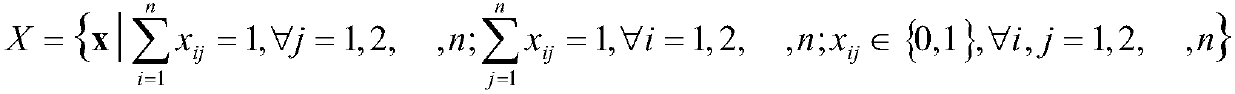

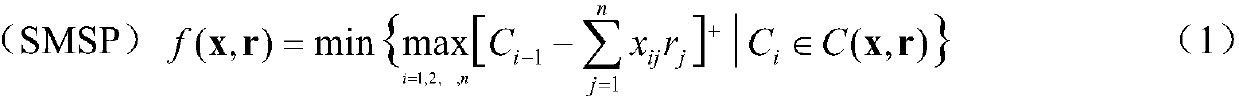

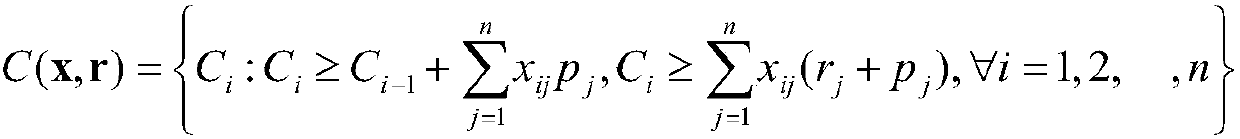

[0072] 1) Construct a robust optimization model RSMSP for single-machine scheduling, which is composed of objective functions and constraints; the specific steps are as follows:

[0073] The present invention focuses on the single-machine scheduling problem with random release time (Job ReleaseTime, JRT). Considering that the workpiece release time is uncertain, seek a workpiece processing sequence that minimizes the maximum waiting time of a single workpiece, and establishes for this problem A robust optimization model RSMSP. In this problem, all workpieces are processed on one machine, and once the workpiece starts processing, it cannot be inter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com