Sheet metal surface anomaly detection method based on image analysis

A metal plate and anomaly detection technology, applied in image analysis, image data processing, optical testing flaws/defects, etc., can solve the problems of incomplete detection, low confidence, lack of quantification, etc., and achieve the goal of improving accuracy and real-time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

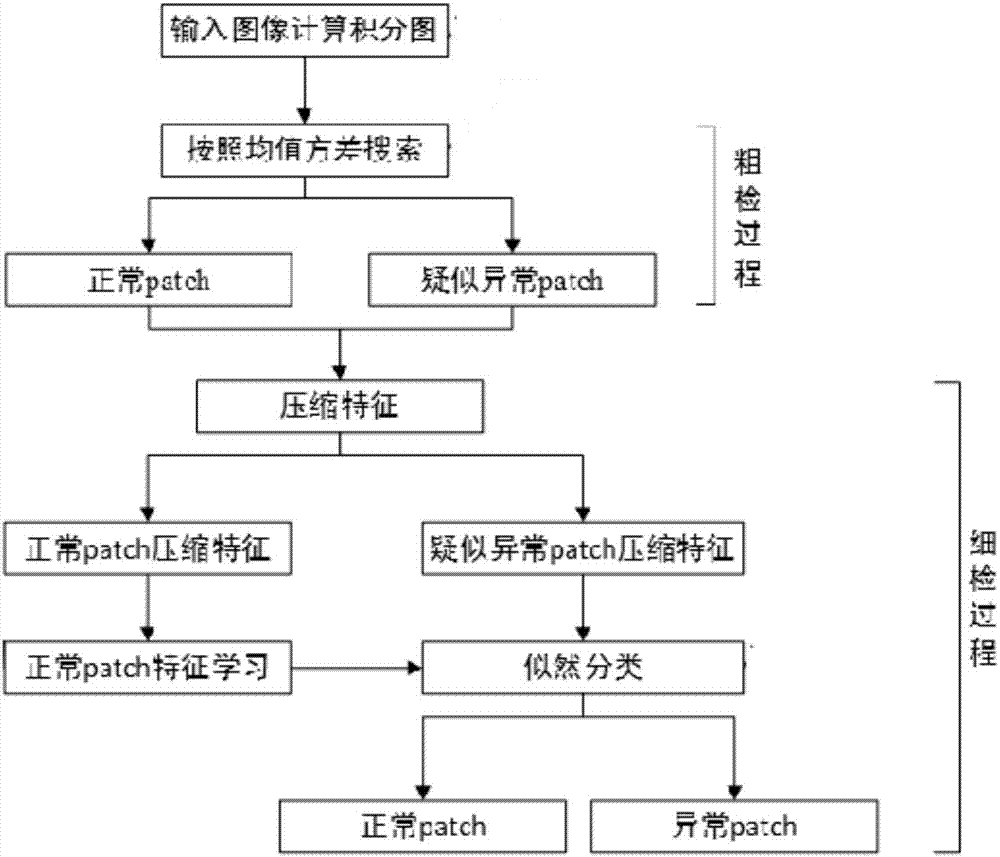

[0069] figure 1 It is a flowchart of a method for detecting anomalies on the surface of metal sheets based on image analysis.

[0070] In this example, if figure 1 As shown, the present invention is a kind of metal plate surface anomaly detection method based on image analysis, comprises the following steps:

[0071] S1. Calculate the integral image of the entire image to be detected

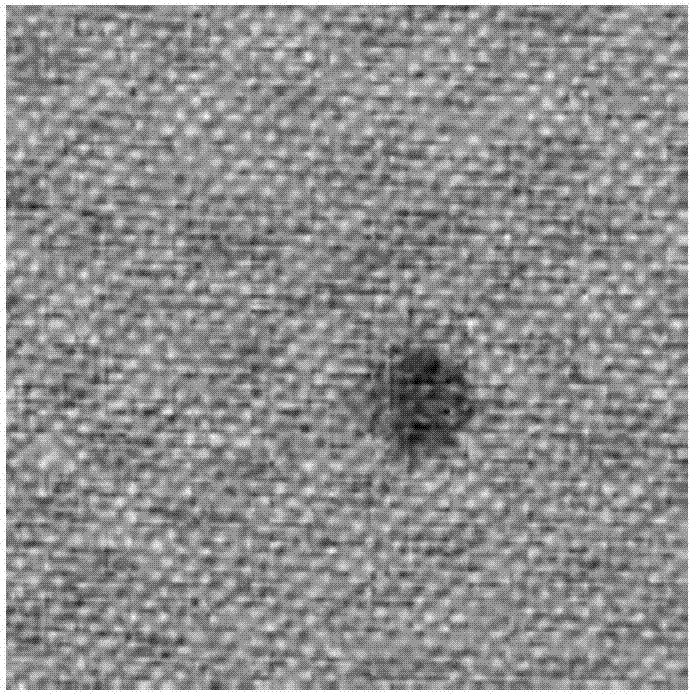

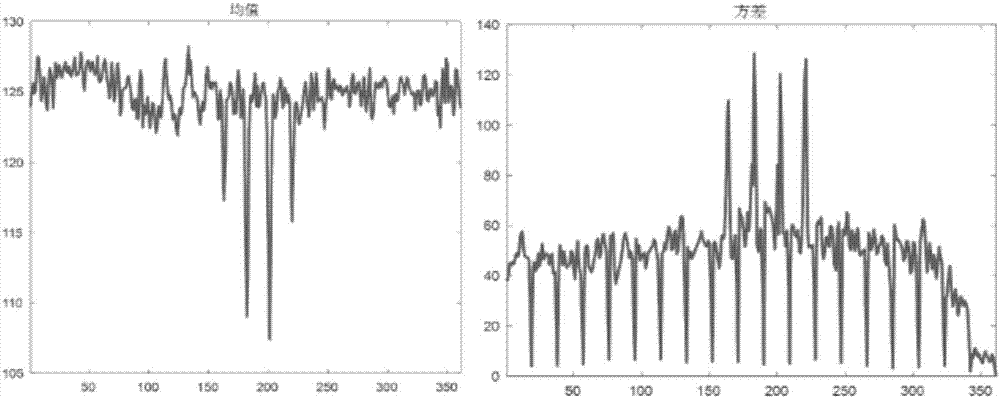

[0072] For an image I to be detected, such as figure 2 As shown, when many rectangles need to be summed for all the pixels in each rectangle, if a separate calculation is performed for each rectangle, obviously there will be a lot of repeated calculations. Therefore, we use the following The formula can be iterated to calculate the integral map of the entire image to be detected

[0073]

[0074] Among them, I(x, y) represents the pixel value at coordinates (x, y), and I′(x, y) represents the sum of pixel values at the upper left corner of the image to be detected at coordinates (x, y)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com