Rotor and rotating shaft connecting structure of smoke exhaust motor

A shaft connection, electromechanical technology, applied in electromechanical devices, magnetic circuit shape/style/structure, electrical components, etc., can solve the problems that magnetic steel sheets are easy to be hit, separated and laborious, and achieve good protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

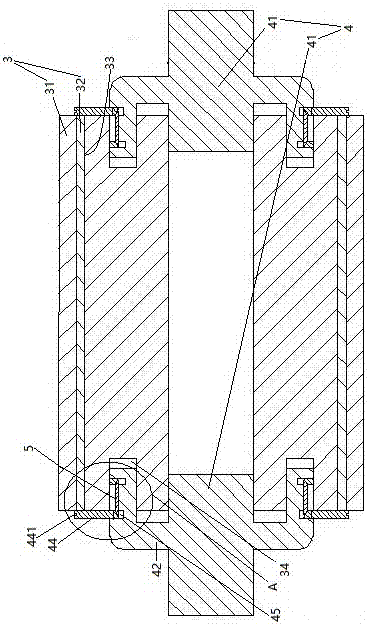

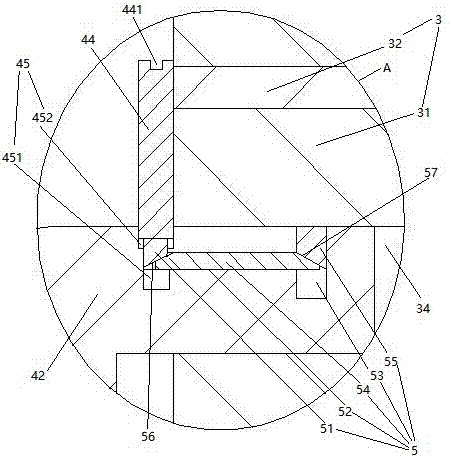

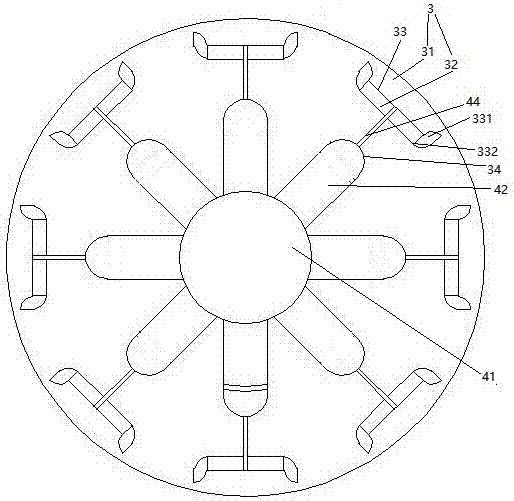

[0017] see figure 1 , a rotor shaft connection structure of a range hood motor, comprising a rotor 3 and a motor shaft 4 .

[0018] The rotor 3 includes a rotor core 31 and several magnetic steel sheets 32 . The rotor core 31 is provided with a plurality of magnetic steel sheet installation through holes 33 extending along the axial direction of the rotor. The number of magnetic steel sheet mounting through holes 33 is equal to the number of magnetic steel sheet 32 . The magnetic steel sheets 32 are arranged one by one in the magnetic steel sheet installation through hole 33, and the two ends of the rotor core 31 are provided with a plurality of insertion holes 34 distributed along the axial extension and circumferential direction of the rotor. The number of insertion holes 34 located at both ends of the rotor core 31 is equal and the number of thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com