Drying device

A technology of drying device and mounting frame, which is applied in the direction of clothing, adhesive shoe parts, shoe-making machinery, etc. It can solve the problems of low efficiency, uneven heating of soles, increased labor force, etc., and achieve high efficiency, simple structure, and uniform heating Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings.

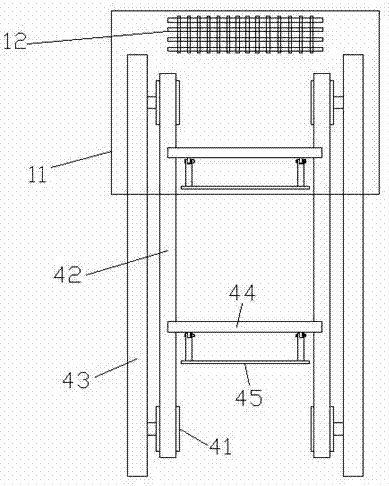

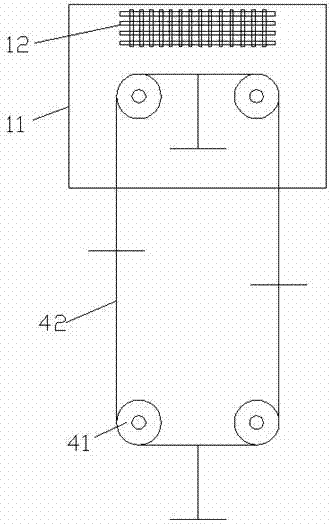

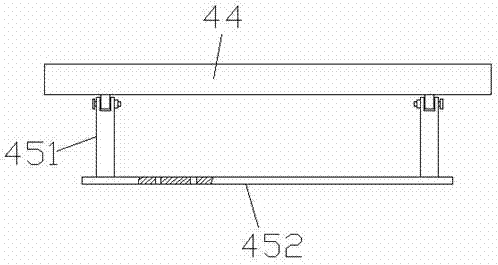

[0013] Such as Figure 1 to Figure 3 As shown, the present invention includes an incubator 11, an electric heater 12, a transmission sprocket 41, a transmission chain 42, a mounting frame 43, a connecting plate 44 and a feeding frame 45, and the electric heater 12 is located in the incubator 11, and the two installations Frames 43 are parallel to each other and are located below the incubator 11, and the tops of the two mounting frames 43 are all stretched in the incubator 11, and 4 transmission sprockets 41 are connected in rotation on each mounting frame 43, and each mounting frame The 4 transmission sprockets 41 on the 43 are distributed in a rectangular shape, and a transmission chain 42 is wound around the 4 transmission sprockets 41 on each mounting frame 43, and the transmission chains 42 on the two mounting frames 43 are parallel to each other. Both ends of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com