Sterilizing equipment for burn surgery department

A technology for sterilizing equipment and equipment, which is applied in the field of medical devices and can solve problems such as improper treatment, chemical burns that cannot be treated in time, and personal injuries.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

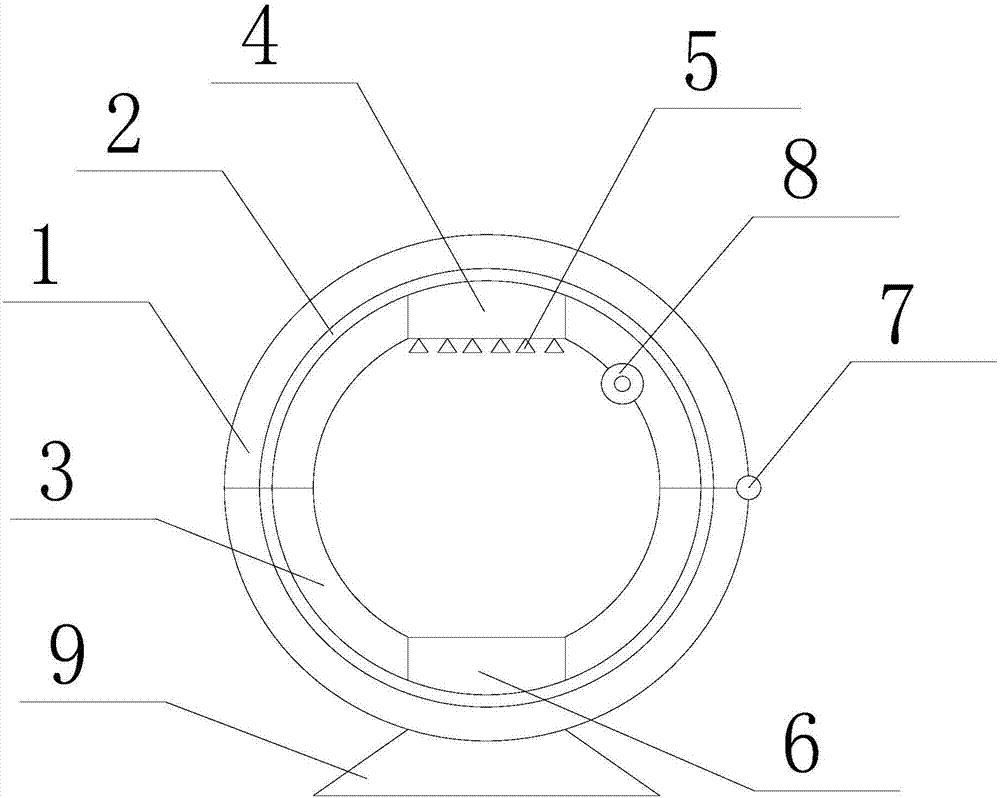

[0023] Such as figure 1 As shown, the present invention is a kind of disinfection equipment for burn surgery, which comprises a shell ring 1, a slide bar ring 2 and a device ring 3 which are sequentially arranged from the outside to the inside; the shell ring 1, the slide bar ring 2 and the device ring 3 It is equally divided into upper and lower parts, and the upper and lower parts of the shell ring 1 are connected by a rotating shaft 7; the device ring 3 is provided with a disinfectant tank 4 and a water collection tank 6 opposite to each other, and the disinfectant tank 4 faces the inside of the device. A spray head 5 is arranged on the surface; a roller 8 is also arranged on the surface of the equipment ring 3 facing the inside of the equipment; the roller 8 is movably connected to the equipment ring 3, and the roller 8 rotates around the movable joint; gauze is wound on the roller 8 , the thickness of the gauze is 3-5 cm, and the gauze is soaked with povidone-iodine. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com