Controllable shutter type work bin for distribution of electronic components

A technology for electronic components and parts boxes, which is applied in the field of distribution and management of electronic components, can solve the problems of few types of storage components, lack of automation functions, inconvenience in component distribution and management, etc., and achieve reasonable structure, easy management, and small size Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

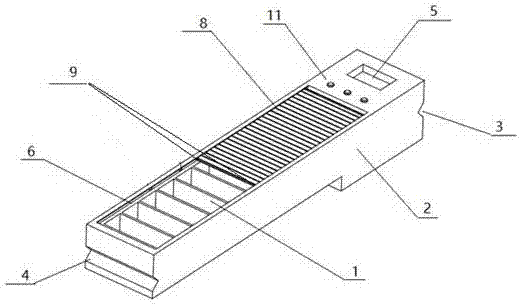

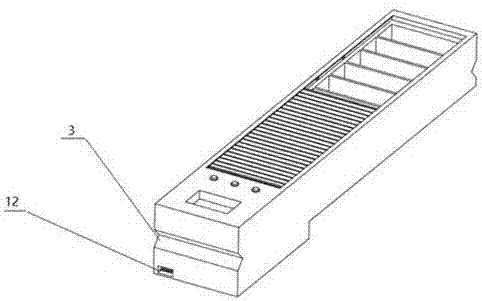

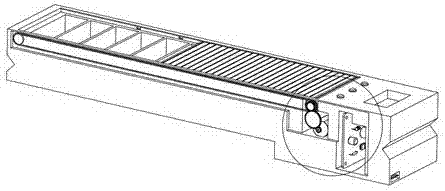

[0023] Embodiment 1: as Figure 1-7 As shown, the controllable rolling shutter type parts box used for distribution of electronic components includes a parts slot 1, a housing bracket 2, an electric rolling shutter 8, a rolling shutter transmission mechanism and a control circuit 14, and the housing bracket 2 is a strip with a length of 50 cm. Shaped box-shaped structure, the part slot 1 is set inside the shell support 2 and is divided into 30 grids along its length direction, and arranged sequentially. The upper opening of the shell support 2 and the two sides of the notch of the part slot 1 are provided with roller shutter guide rails 6. The curtain 8 is driven by the roller shutter transmission mechanism and installed on the roller shutter guide rail 6. The roller shutter transmission mechanism and the control circuit 14 are located inside the top of the housing bracket 2; the roller shutter transmission mechanism is composed of a motor 10, a gear set 7 and a roller shade sh...

Embodiment 2

[0026] Embodiment 2: as Figure 1-7 As shown, the controllable rolling shutter type parts box used for distribution of electronic components includes a parts slot 1, a housing bracket 2, an electric rolling shutter 8, a rolling shutter transmission mechanism and a control circuit 14, and the housing bracket 2 is a length of 70 cm. Bar-shaped box-shaped structure, the part slot 1 is set inside the shell support 2 and is divided into 15 grids along its length direction, and arranged in sequence. The upper opening of the shell support 2 and the two sides of the notch of the part slot 1 are provided with roller shutter guide rails 6, electric The roller shutter 8 is driven by the roller shutter transmission mechanism and installed on the roller shutter guide rail 6. The roller shutter transmission mechanism and the control circuit 14 are arranged inside the top of the shell bracket 2; the roller shutter transmission mechanism is composed of a motor 10, a gear set 7 and a roller shu...

Embodiment 3

[0029] Embodiment 3: as Figure 1-7 As shown, the controllable rolling shutter type parts box used for distribution of electronic components includes a parts slot 1, a housing bracket 2, an electric rolling shutter 8, a rolling shutter transmission mechanism and a control circuit 14, and the housing bracket 2 is a strip with a length of 60 cm. Shaped box-shaped structure, the part slot 1 is set inside the shell support 2 and is divided into 20 grids along its length direction, and arranged sequentially. The upper opening of the shell support 2 and the two sides of the notch of the part slot 1 are provided with roller shutter guide rails 6. The curtain 8 is driven by the roller shutter transmission mechanism and installed on the roller shutter guide rail 6. The roller shutter transmission mechanism and the control circuit 14 are located inside the top of the housing bracket 2; the roller shutter transmission mechanism is composed of a motor 10, a gear set 7 and a roller shade sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com