Container loading and unloading rain shed

A container and canopy technology, which is applied in the field of unloading rain canopy and container loading, which can solve the problems of cartons getting wet, affecting shipments, and unable to solve the problems of cargo loading and unloading.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

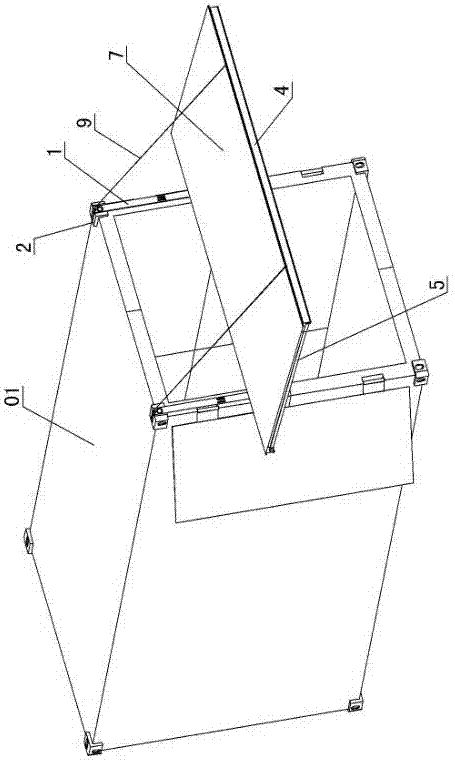

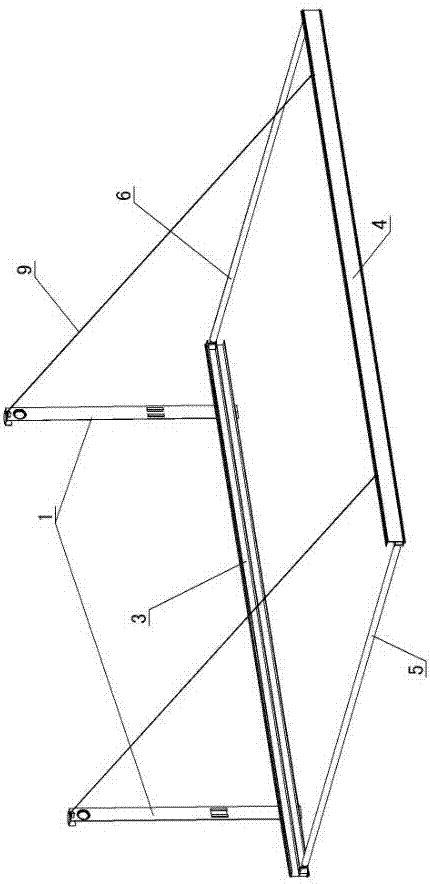

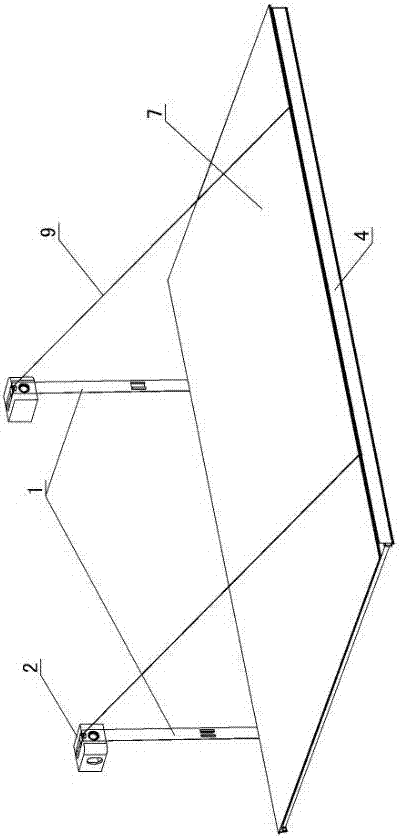

[0014] The invention relates to a container loading and unloading canopy, such as figure 1 — Figure 7As shown, the canopy is set at the door of the container (also known as the container). The four corners of the container 01 have corner fittings 2 for crane hoisting. The canopy can be directly installed on the corner fittings, but the container is relatively high (the distance from the top of the container The ground is more than 4 meters), if it is installed directly on the corner fittings, the installation is troublesome and the stability is poor, so the corner fittings of the container are first connected with the connecting rods, and then connected with the brackets (support rods) of the canopy through the connecting rods, The height of canopy reduces like this, and it is convenient to install and dismantle. There is a top hole at the top of the corner fitting, which is called a fixed top hole 21 here, and there is a circular hole on the side wall of the corner fitting, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com