Railway track maintenance machine based on collaborative operation mode of mother machine and son machine

A technology of collaborative work and railway track, applied in the direction of track, track laying, track maintenance, etc., can solve the problems of heavy workload, low detection frequency, high risk, achieve high degree of automation and intelligence, improve work efficiency, improve The effect of measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with accompanying drawing.

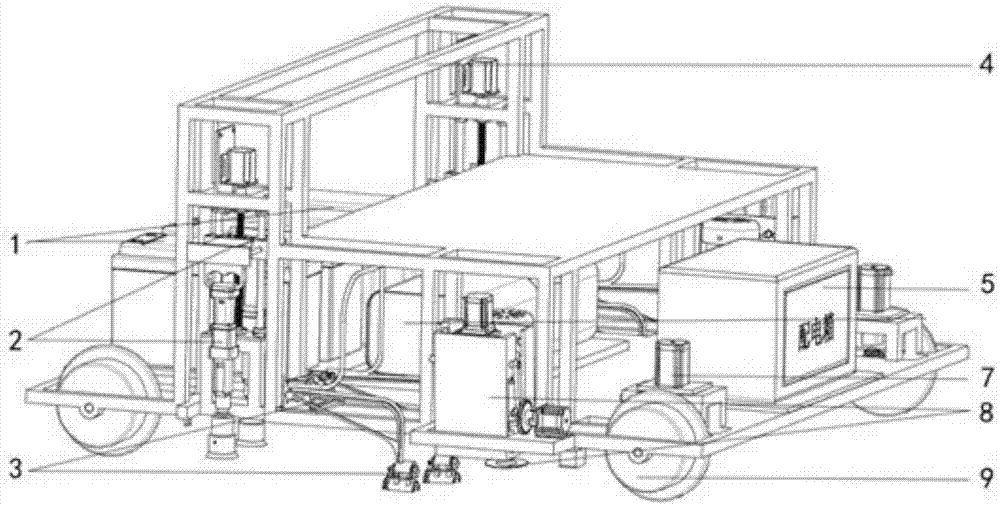

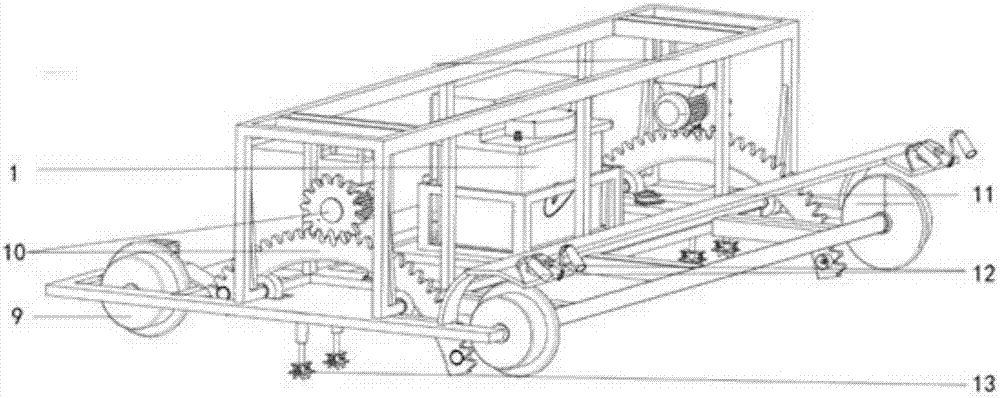

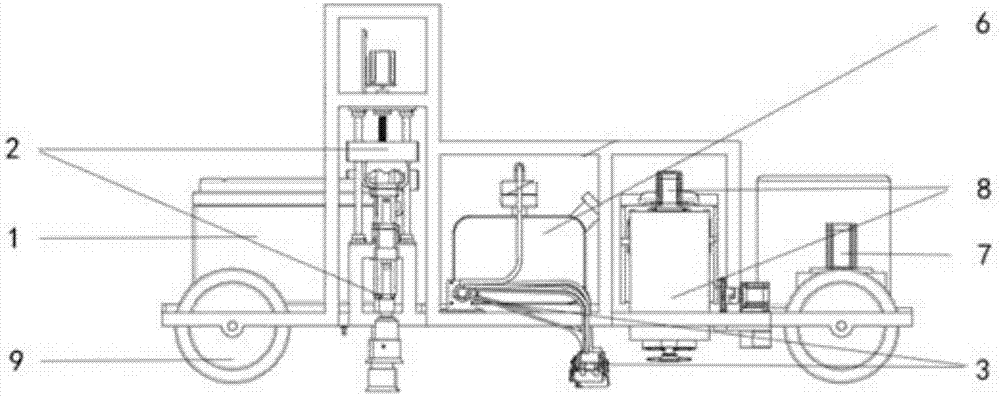

[0037] Such as Figure 1-8 As shown, the present embodiment provides a railway track overhauling machine based on the synergistic working mode of the sub-master machine, including a host computer, a main machine and a sub-machine, the main machine performs detection work, and the sub-machine performs maintenance work. Walking wheels are provided, a storage battery 1, an irregularity detection module 11, a defect detection module 12, a bolt looseness detection module 13, and a gauge detection module 10 are arranged on the frame 4 of the main machine. Walking wheel is provided with accumulator, bolt screwing device 2 and oiling device 3, grinder 8, power distribution box 5, oil tank 6, walking wheel driving motor 7 on sub-machine frame. Among them, the irregularity detection module 11, the defect detection module 12, the bolt looseness detection module 13, and the gauge dete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com