Outdoor same-floor deodorant, leak-proof and energy-saving 5-liter water drainage system of ground-drainage toilet

A technology for drainage systems and toilets, applied in flush toilets, water supply devices, buildings, etc., can solve problems such as large drop and increase drainage resistance, and achieve the effect of low cost and less backfill

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

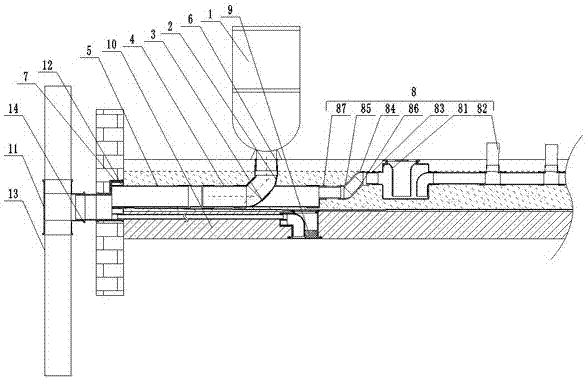

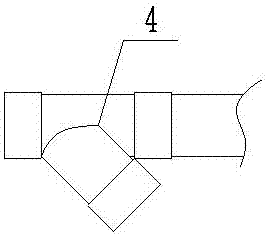

[0039] Such as figure 1 , figure 2As shown, the present invention has an outdoor same-floor anti-odor, leak-proof and energy-saving floor toilet with 5 liters of water drainage system, including a toilet 1, a first 45° elbow 2, a second 45° elbow 3, a 45° oblique tee 4 and a drainage branch pipe 5 , the three ends of the 45° oblique tee 4 are arranged horizontally, the longitudinal ends of the 45° oblique tee 4 communicate with the drainage branch pipe 5, and the 45° pipe of the 45° oblique tee 4 is connected to the first The lower ends of the two 45° elbows 3 are connected, the upper end of the second 45° elbow 3 is connected with the lower end of the first 45° elbow 2, and the upper end of the first 45° elbow 2 is connected with the toilet 1, so The upper end of the first 45° elbow 2 is set vertically upwards, and the central axis of the upper end of the first 45° elbow 2 and the central axis of the lower end of the second 45° elbow 3 are out-of-plane straight lines, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com