Spiral plate type heat exchanger for instant noodles

A spiral plate heat exchanger technology, applied in indirect heat exchangers, heat exchange equipment safety devices, heat exchange equipment, etc., can solve problems affecting the service life of palm oil and achieve the effect of extending service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

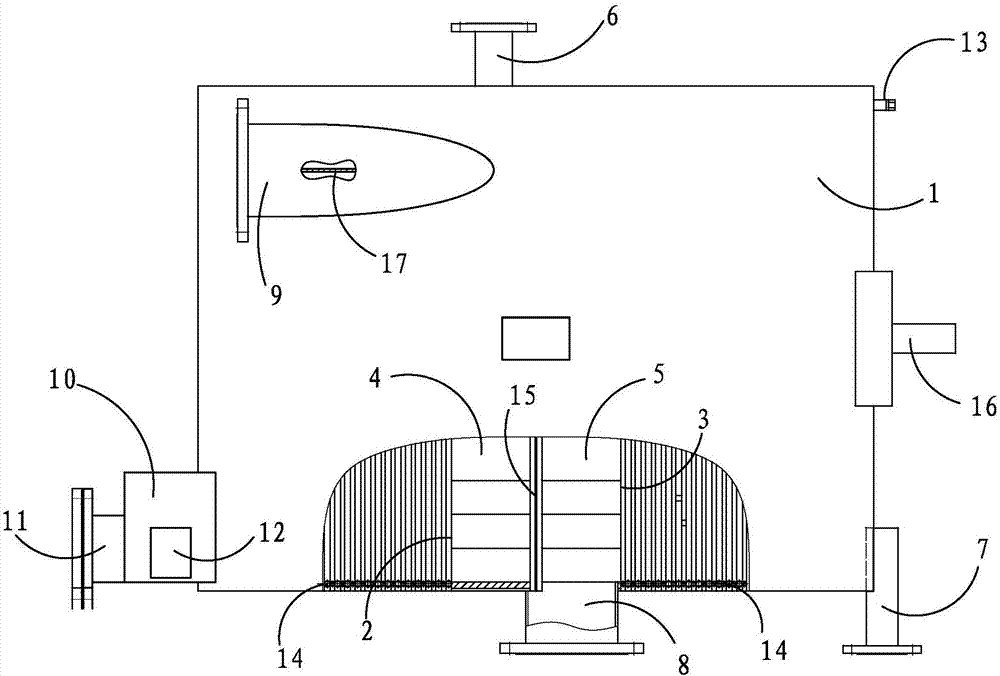

[0016] The present invention will be further described below in conjunction with the embodiment shown in accompanying drawing:

[0017] See attached figure 1 As shown, a spiral plate heat exchanger for instant noodles includes a horizontally placed cylindrical shell 1 and a heat exchange device arranged in the shell 1. The heat exchange device includes a first spirally wound coil. A heat exchange plate 2 and a second heat exchange plate 3, and a spacer column arranged between the first heat exchange plate 2 and the second heat exchange plate 3, the space in the housing 1 is covered by the first heat exchange plate 2 and the second heat exchange plate 3 The second heat exchange plate 3 is divided into a spiral first heat exchange channel 4 and a second heat exchange channel 5. The first heat exchange channel 4 has a steam inlet 6 located in the middle of the upper bottom surface of the shell 1 and a steam inlet 6 located on the side wall of the shell 1. The condensate outlet 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com