Oil-electric-hydraulic hybrid power system with self-powered front shaft and self-powered rear shaft and conversion method of different working patterns

A technology of hybrid power system and independent drive, which is applied in hydraulic hybrid power system, electric, oil-electric-hydraulic hybrid power system, and oil field, and can solve problems such as complex structure, increase energy recovery rate, reduce motor loss, enhance passing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

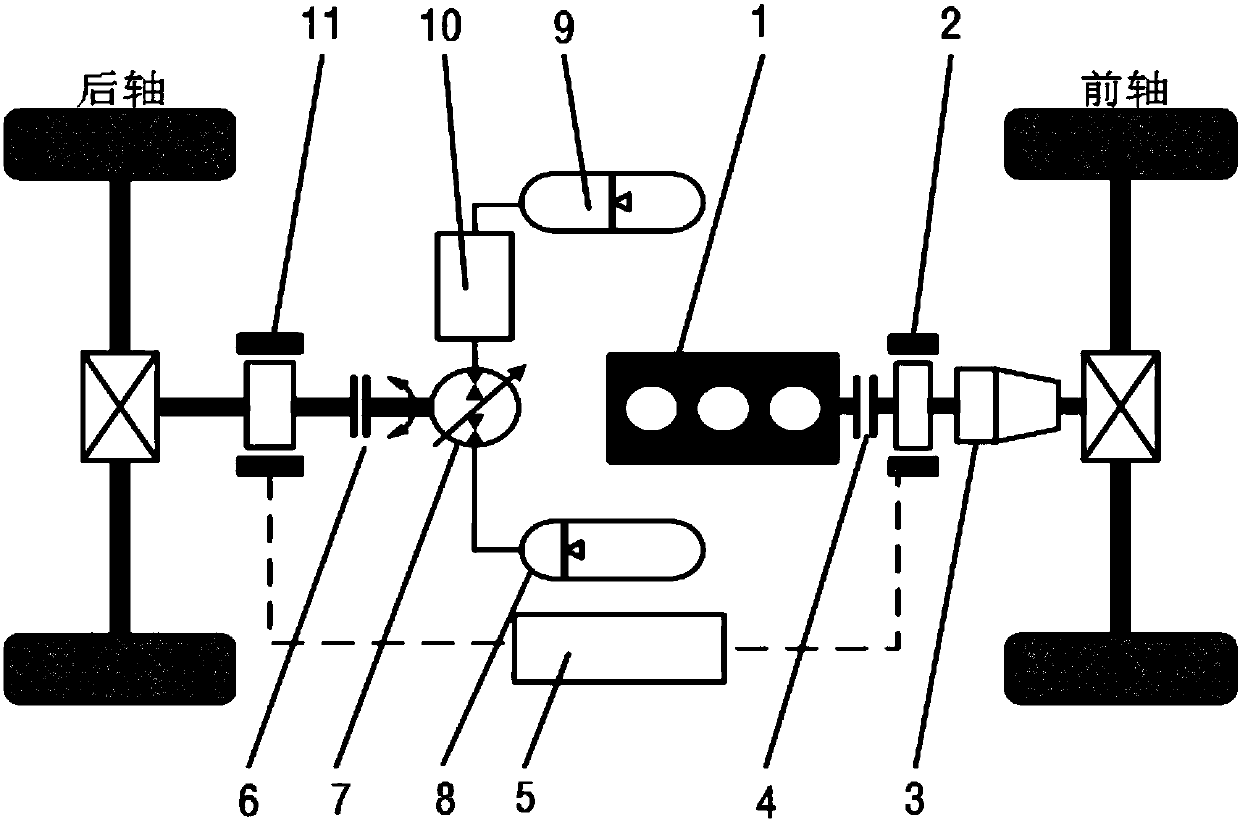

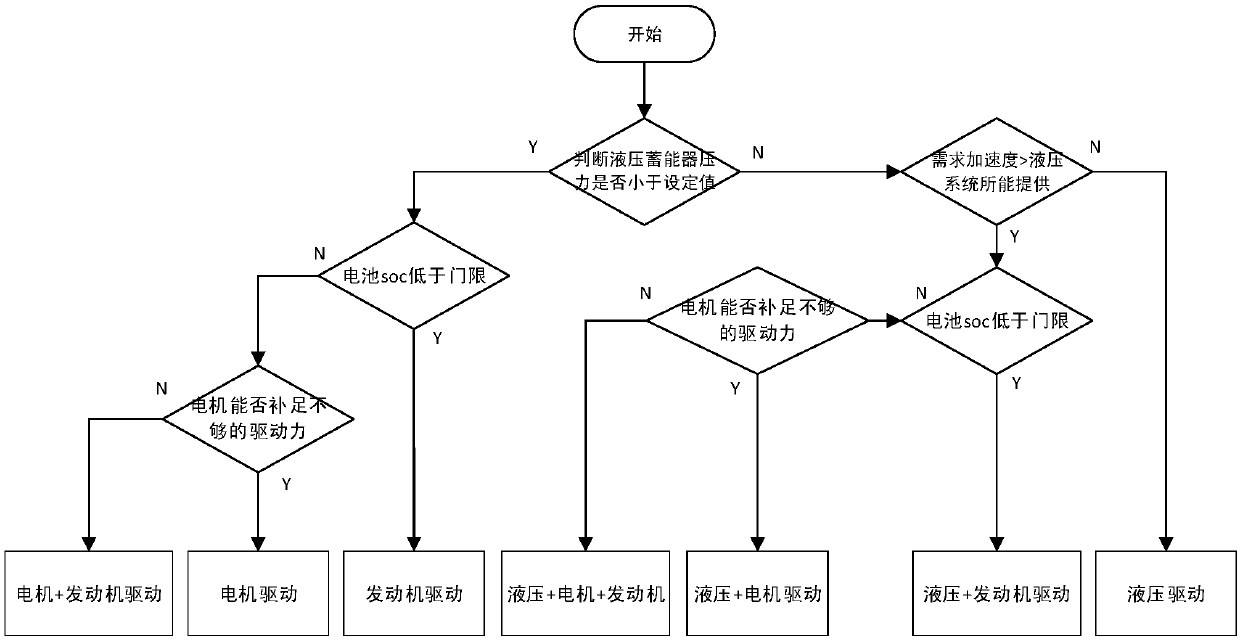

[0046] The embodiment is basically as attached figure 1 Shown: This embodiment provides an oil-electric-hydraulic hybrid system with front and rear axles independently driven, including a gearbox 3, a battery 5, a front axle oil-electric hybrid that is independently connected to the front axle of the vehicle through the gearbox 3, and a vehicle Rear axle electro-hydraulic hybrid with independent connection of the rear axle, the front axle oil-electric hybrid includes engine 1 and front axle motor 2, which are used to provide driving force to the front axle and recover the braking energy of the front axle of the vehicle by the front axle motor 2 ; The rear axle electro-hydraulic hybrid power includes a hydraulic unit and a rear axle motor 11, which are used to provide driving force to the rear axle and absorb the braking energy of the rear axle of the vehicle by the hydraulic unit; wherein, the engine 1 and the front axle motor 2 pass through the front Shaft clutch 4 is coupled...

Embodiment 2

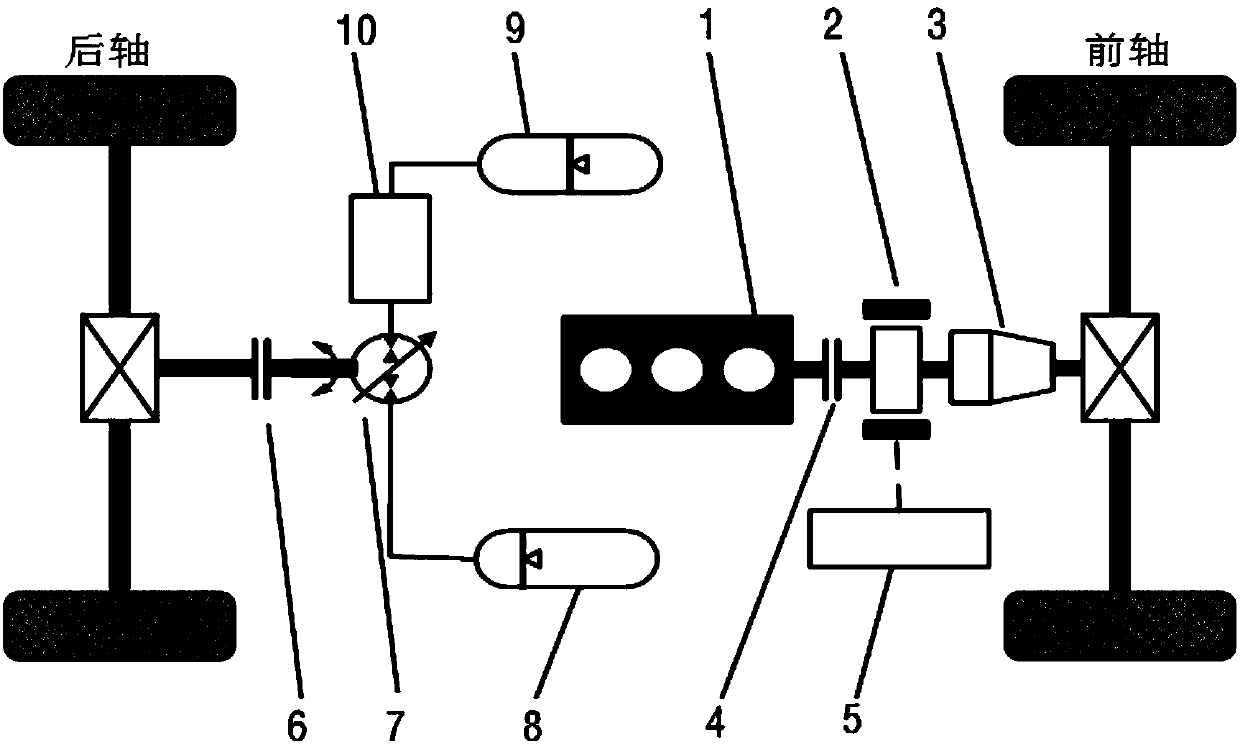

[0072] In addition, the oil-electric-hydraulic hybrid power system involved in the present invention also includes another expanded form such as the attached figure 2 , that is, the front axle is an oil-electric coaxial parallel hybrid system, and the rear axle is purely hydraulically driven, that is, the rear axle motor 11 is missing. The principle of judging the driving mode and braking mode is the same as that of the front axle independent drive system of the front axle oil-electric hybrid and the rear axle electro-hydraulic hybrid, so I won’t repeat them here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com