Integrated type heat dissipation apparatus

A heat sink, integrated technology, used in cooling/ventilation/heating retrofits, electrical components, electrical equipment structural parts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0116] The above-mentioned purpose of the present invention and its structural and functional characteristics will be described according to the embodiments of the accompanying drawings.

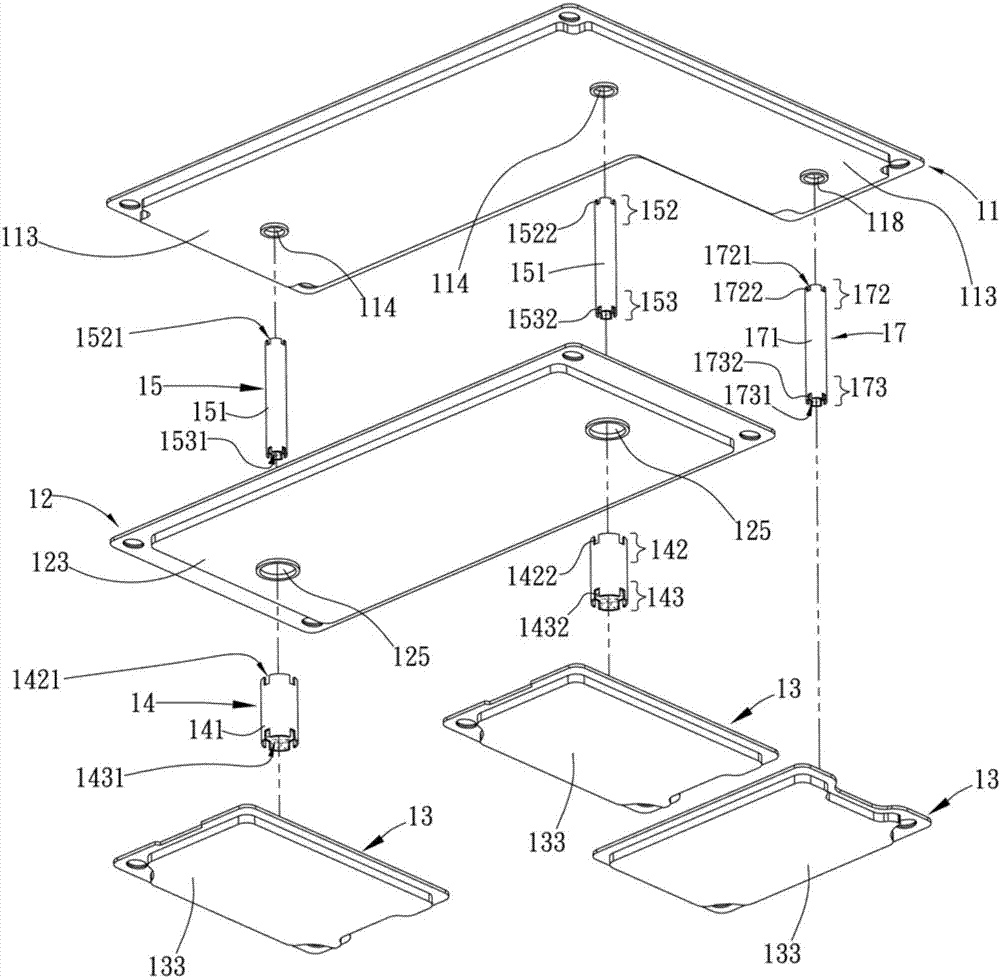

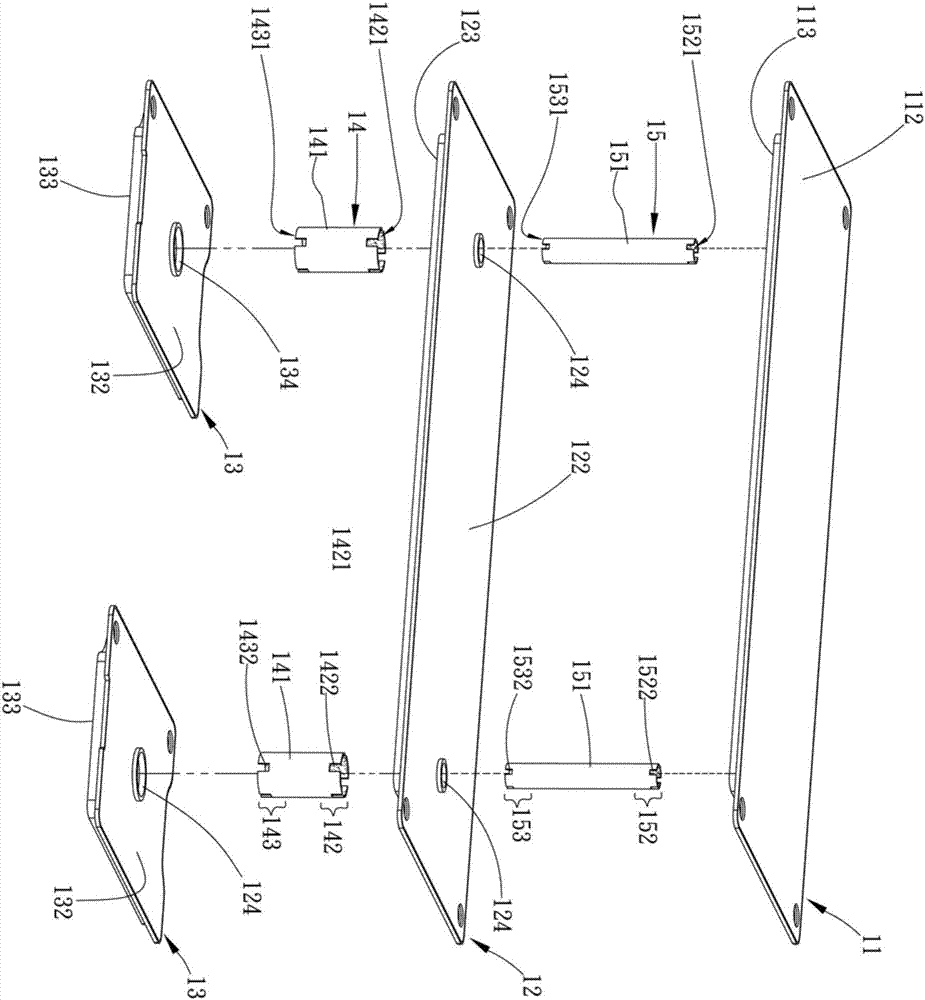

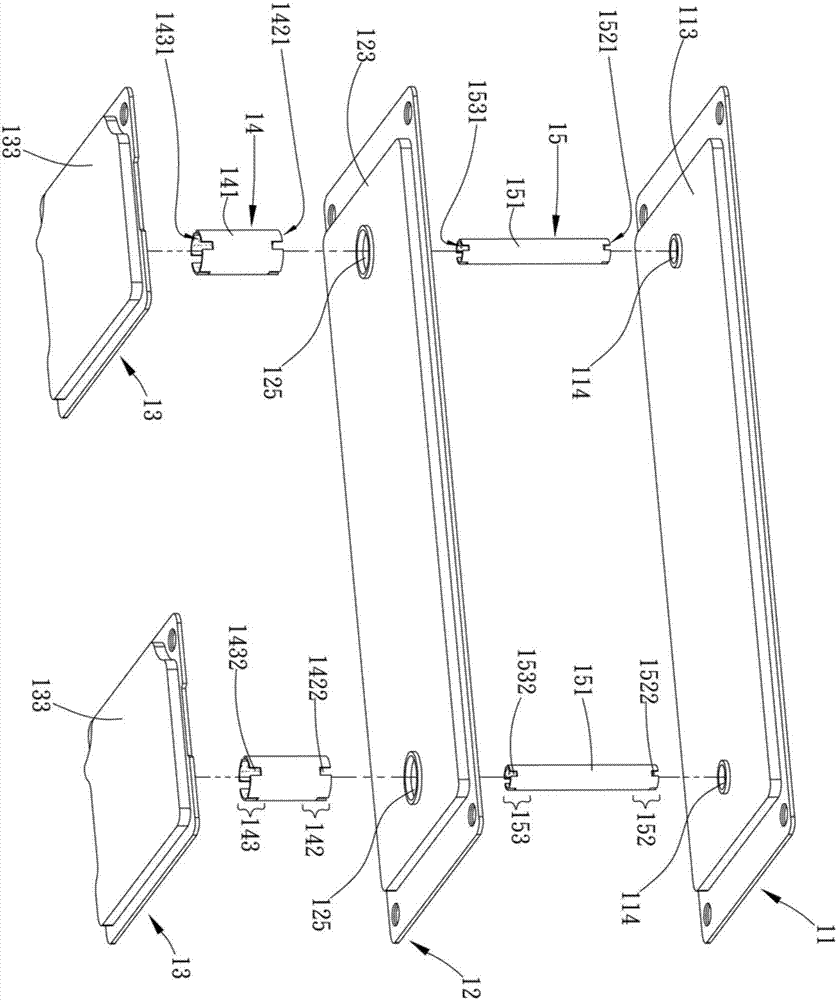

[0117] The present invention provides an integrated cooling device, please refer to Figure 1A , Figure 1B , figure 2 , is a three-dimensional decomposition and assembly diagram of the first embodiment of the present invention. As shown in the figure, the integrated heat dissipation device includes at least one first shell 11, one second shell 12, multiple third shells 13, multiple first heat pipes 14 and at least one second heat pipe 15, the first shell The body 11 in this embodiment means that a first shell 11 is located above the second shell 12, and the third shells 13 in this embodiment mean that two third shells 13 are located below the second shell 12 and Arranged in a left-right arrangement. The first housing 11 , the second housing 12 and the second housings 12 are preferably m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com