Stuffing preparation device

A technology for making devices and fillings, which is applied in the field of mixing equipment, which can solve the problems of increased probability of contamination, easy to be bitten and climbed by mosquitoes, and complicated operation, so as to improve food safety and improve mixing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

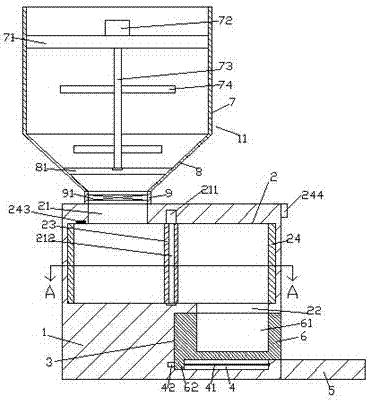

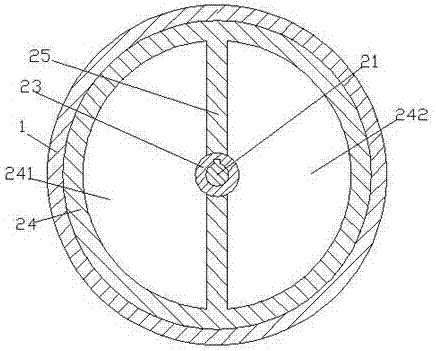

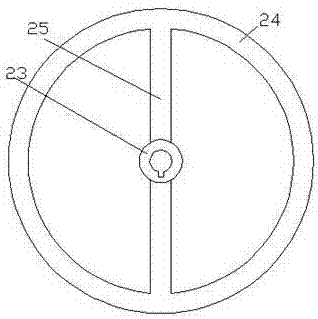

[0021] Such as Figure 1-Figure 6 As shown, a stuffing making device of the present invention includes a base body 1 and a material box 11 arranged above the base body 1. The material box 11 includes a first tapered portion 7, and is arranged on the first tapered portion. The second tapered part 8 at the bottom of the part 7 and the third tapered part 9 arranged at the bottom of the second tapered part 8, the inside of the base body 1 is provided with a first container 2, and the first container 2 The top of the left side is provided with a first slot 21 transparent to the third tapered portion 9, the bottom of the right side of the first container 2 is provided with a second slot 22, and the bottom of the second slot 22 is The base body 1 is provided with a second storage tank 3, the base body 1 at the bottom of the second storage tank 3 is provided with a chute 4, and the first storage tank 2 is provided with a pipe sleeve for operation fit connection 24, the inner center o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com