A food processing device

A food processing device and packaging technology, which is applied to kitchen utensils, household utensils, applications, etc., can solve the problems of long stirring time, forgotten stirring time, and high cost of use, so as to improve the uniformity of stirring, the range of stirring, and the efficiency of stirring Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

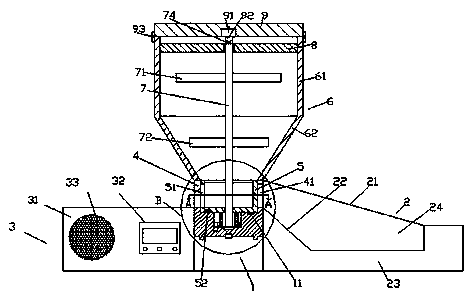

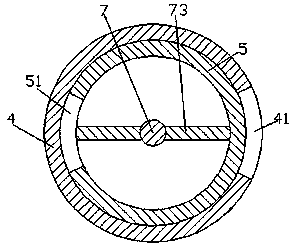

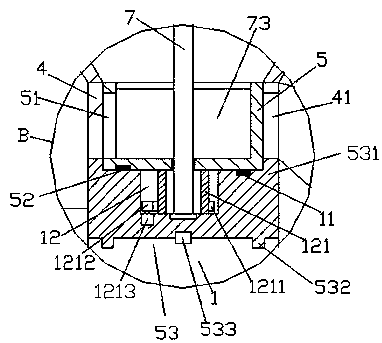

[0023] Such as Figure 1-Figure 5 As shown, a food processing device of the present invention includes a body 1, a reminder part 3 arranged on the left side of the body 1, a holding part 2 arranged on the right side of the body 1, and a Mixing part 6, the top of the body 1 is provided with a ring body 4, the body 1 at the bottom of the ring body 4 is provided with an accommodating cavity 12, and the ring body 4 is provided with a steering fit Connected with a steering sleeve 5, a first opening 41 is provided in the right side wall of the inserting ring body 4, a second opening 51 is provided in the left side wall of the steering sleeve 5, and a second opening 51 is provided in the accommodating cavity 12 There is a steering sleeve 121 whose top is fixedly connected with the bottom of the steering sleeve shell 5, and the outer surface of the steering sleeve 121 is fixed with an external toothed disc 1211, and the left side of the external toothed disc 1211 is connected with a t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com