Circular locus crowned tooth forming grinding swing device

A technology for forming grinding and swinging devices, which is applied to feeding devices, gear teeth, components with teeth, etc., can solve the problem that the use requirements of high-precision machining quality of drum teeth cannot be met, and the flexible adjustment processing of drum teeth cannot be realized. , The high processing accuracy of drum teeth can save installation space, achieve precise control and high sliding accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Embodiments of the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solutions of the present invention more clearly, and therefore are only examples, rather than limiting the protection scope of the present invention.

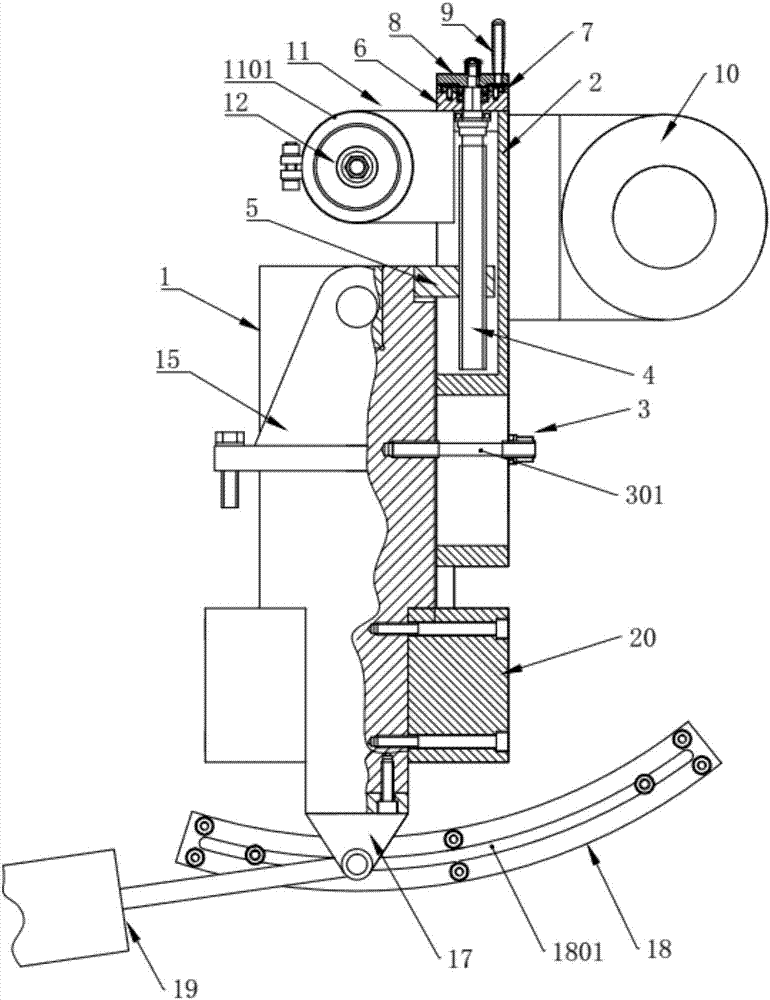

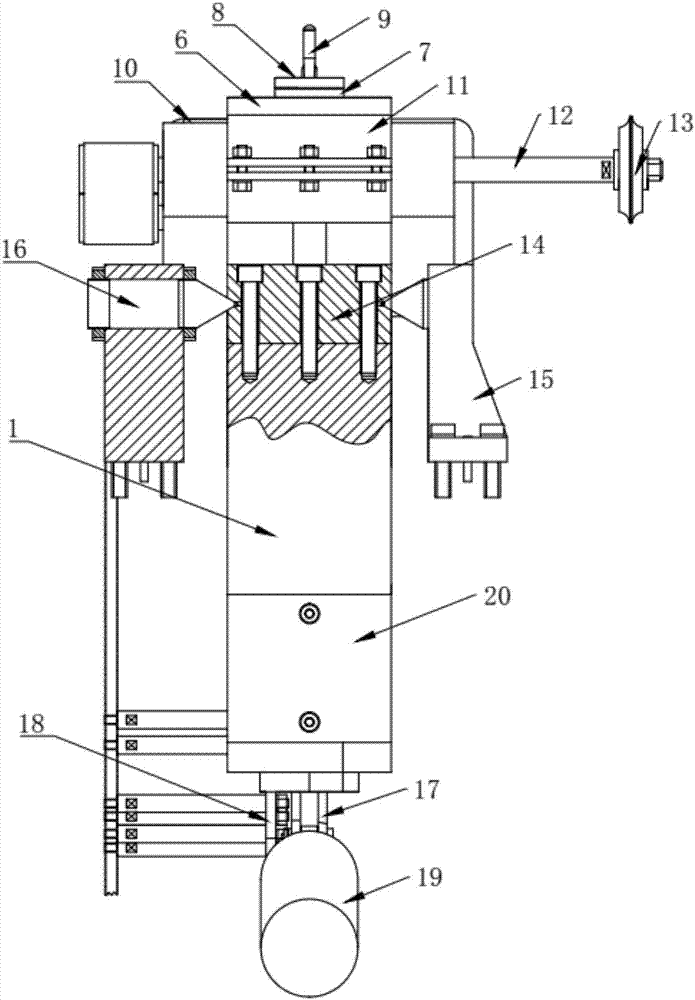

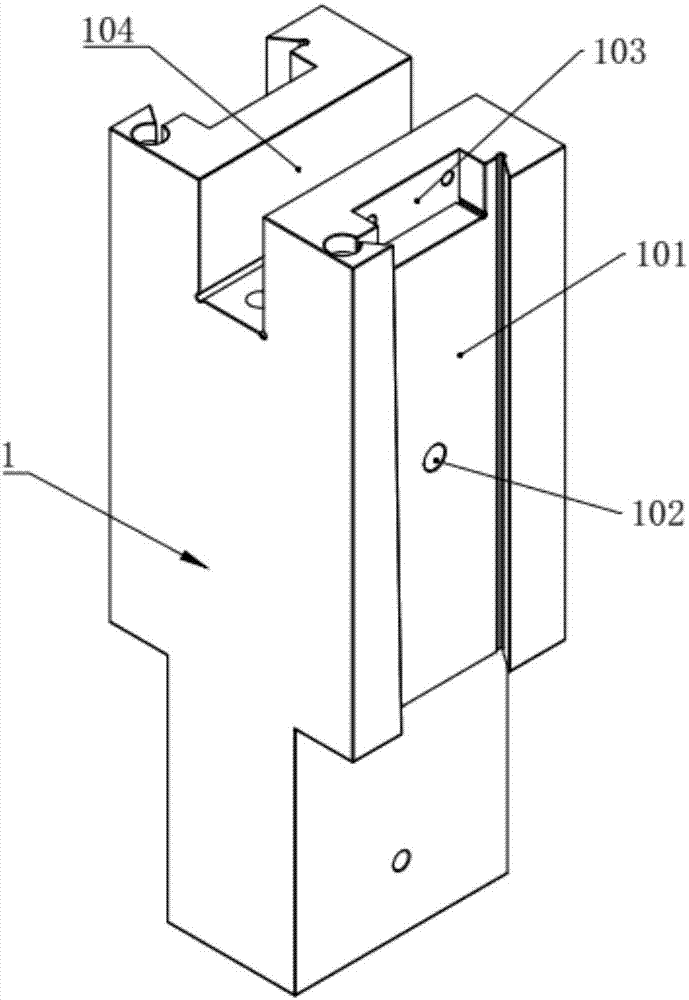

[0041] Such as figure 1 and figure 2 As shown, the present invention provides a circular trajectory drum-shaped tooth forming grinding rocking device, including a rocker arm 1, a grinding head support plate 2 is slidably installed on one side of the rocker arm 1 through a dovetail groove inlay structure, the rocker arm 1 and the grinding wheel The structure of the head support plate 2 is respectively as image 3 and Figure 4As shown, in this embodiment, the rocker arm 1 is provided with a female head 101 with a dovetail groove inlaid structure, and the grinding head supporting plate 2 is provided with a male h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com