Unstacking production line

A production line and depalletizing machine technology, which is applied to the depalletizing of objects, conveyors, conveyor objects, etc., can solve the problems of poor stability, low degree of mechanization, and low depalletizing efficiency, so as to improve the degree of automation and improve work efficiency , The effect of improving the efficiency of unstacking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

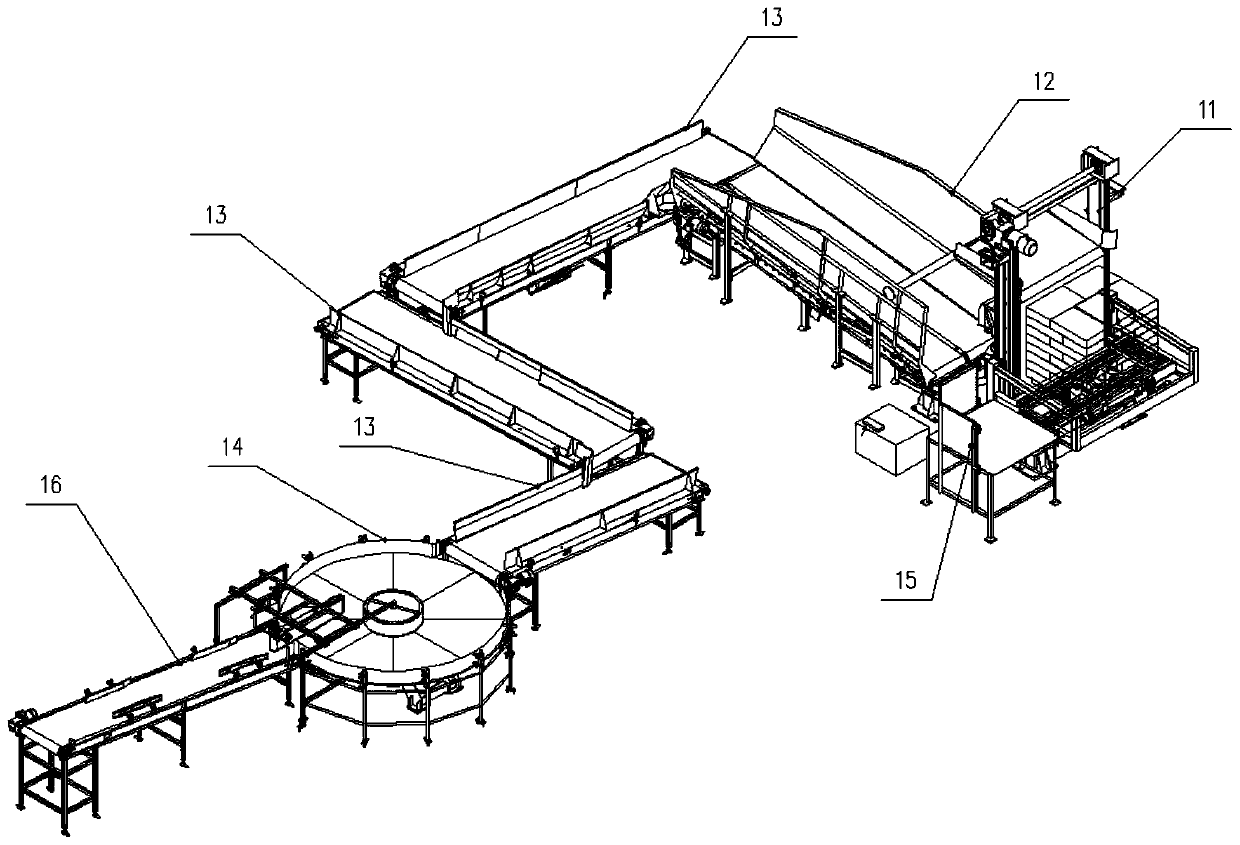

[0068] Specific implementation mode one: combine figure 1 Describe this embodiment, the depalletizing production line of this embodiment comprises depalletizing machine 11, lane divider 12, first belt conveyor 13, disc shaper 14 and second belt conveyor 16;

[0069] The output end of the unstacking machine 11 is connected with the input end of the lane divider 12, and the output end of the lane divider 12 is connected with the input end of the disc shaping machine 14 through one or more first belt conveyors 13, The output end of the disc shaper 14 is connected with one or more second belt conveyors 16; the depalletizer 11 is used to separate the stacked goods layer by layer and transport them to the lane divider 12, and the lane divider 12 Convey the split single-layer goods, and transport the goods to the disc shaping machine 14 via one or more first belt conveyors 13 by means of differential conveying, and the disc shaping machine (14 will carry the goods horizontally The a...

specific Embodiment approach 2

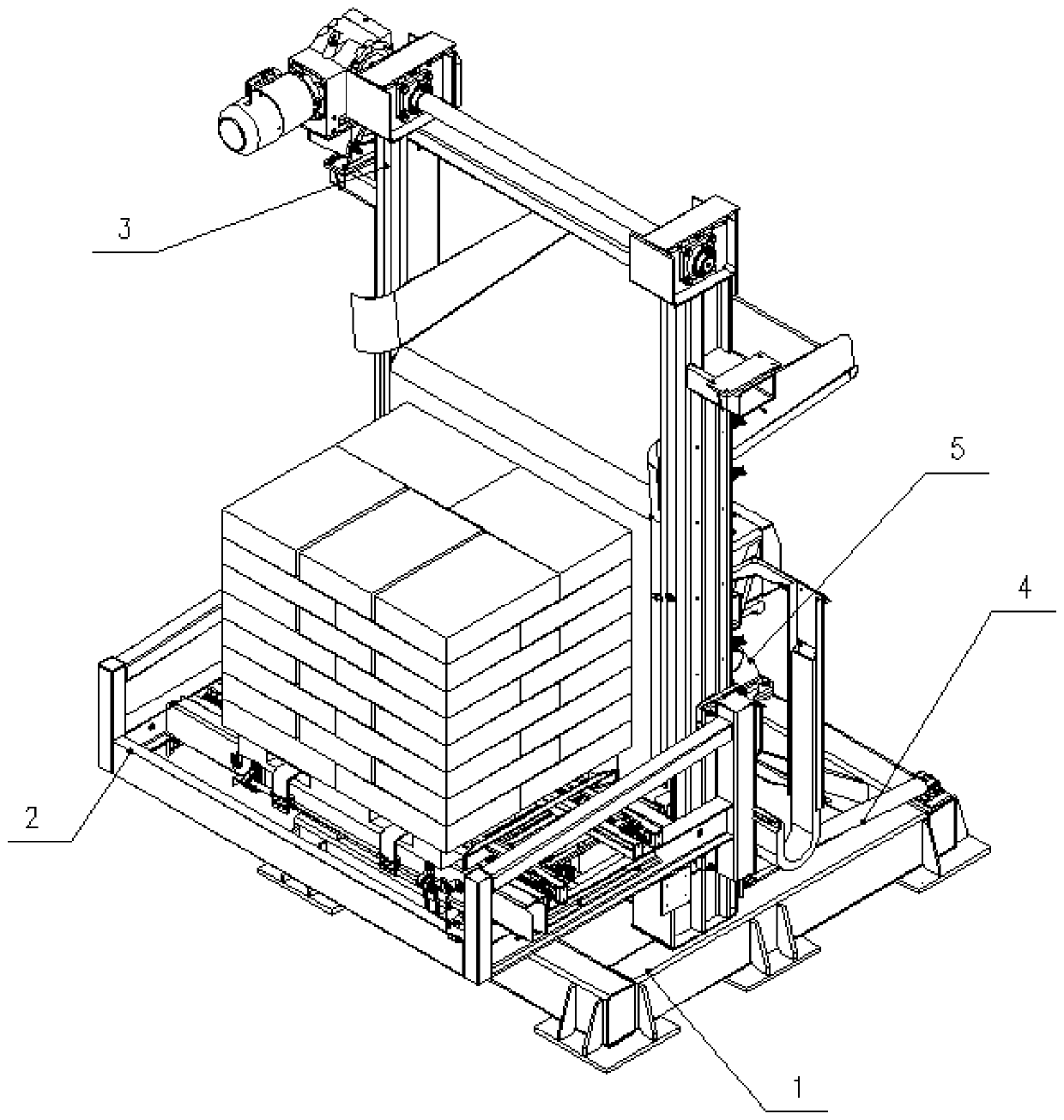

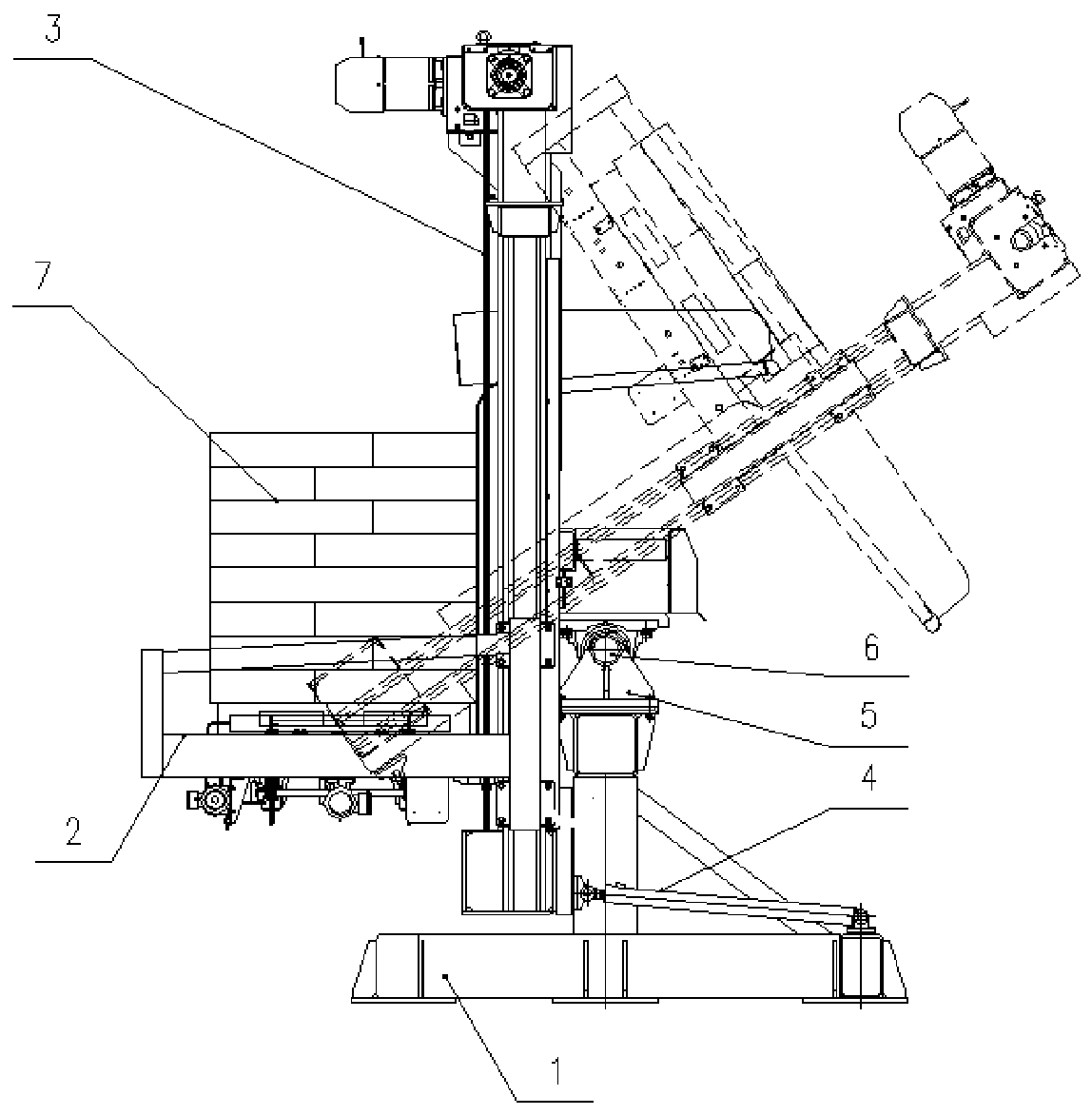

[0072] Specific embodiment 2, combining Figure 2-Figure 5 , Figure 13-Figure 15 Describe this embodiment, the unstacking machine 11 of the unstacking production line of this embodiment comprises base 1, elevating platform 2, elevating device 3, hydraulic cylinder 4 and overturn axle seat 5, and overturn axle seat 5 is installed on base 1, and elevating device 3 is hingedly installed on the turning shaft seat 5 through the turning center shaft 6, the cylinder end of the hydraulic cylinder 4 is installed on the base 1, the output end of the hydraulic cylinder 4 is connected with the lifting device 3, and the lifting platform 2 Installed on the lifting device 3, the lifting platform 2 performs linear reciprocating motion on the lifting device 3. In such a setting, turning over the shaft seat 5 realizes the hinged state of the base 1 and the lifting device 3, and under the push of the hydraulic cylinder 4, the lifting device 3 can achieve pitching motion relative to the base 1,...

specific Embodiment approach 3

[0073] Specific implementation mode three: combination figure 2 , Image 6 Describe this embodiment, the base 1 of the destacking machine 11 of the destacking production line of this embodiment includes a base frame 1-1, a door frame 1-2 and an oil cylinder tailstock 1-3, and the base frame 1-1 is made of square tube welding The formed square frame, the door frame 1-2 and the cylinder tailstock 1-3 are all fixedly installed on the base frame 1-1, and the cylinder end of the hydraulic cylinder 4 is hinged on the oil cylinder tailstock 1-3. The top of the door frame 1-2 is processed with a flange mounting seat, and the turning shaft seat 5 is installed on the top of the door frame 1-2 by means of a flange; in this way, the base frame 1-1 is a square frame made of square pipe welding , in order to strengthen the structural strength of the base 1, support beams and ribs can also be added inside the square frame, wherein the door frame 1-2 can be installed on the base frame 1-1 b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com