Woodwork nail-shooting processing robot

A technology for wood products and robots, which is applied in the field of wood product nailing processing robots, can solve the problems of unfavorable precise positioning of nailing positions, complex intermediate drive mechanism, and low positioning accuracy, and achieve simplified structure, low manufacturing cost, and accurate positioning high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

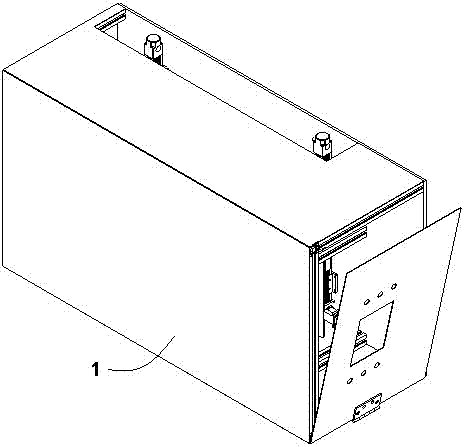

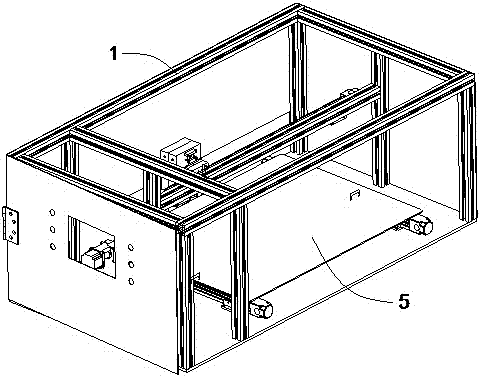

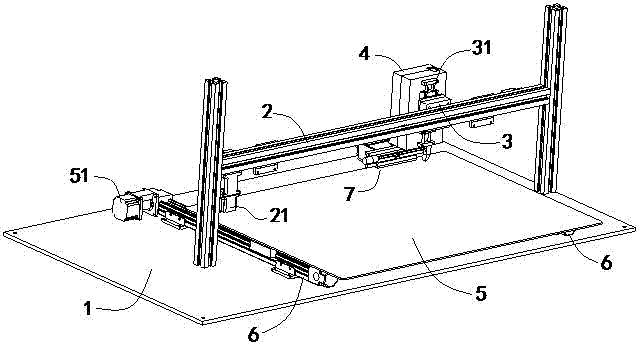

[0017] Such as figure 1 , figure 2 and image 3 As shown, the wood product nailing processing robot of the present embodiment includes a frame 1, on which a horizontal slide rail assembly 2 is arranged horizontally, on which the horizontal slide rail assembly 2 is provided with a lifting platform 3 that can slide horizontally and A horizontal driver 21 for driving the lifting platform 3 to slide horizontally. The lifting platform 3 is provided with a nail gun module 4 that can slide vertically and a vertical driver 31 that drives the nail gun module 4 to slide vertically. 1 is provided with a wooden product sliding tray 5, a longitudinal slide rail assembly 6 is provided between the frame 1 and the wooden product sliding tray 5, and the frame 1 is provided with a longitudinal driver 51 for driving the wooden product sliding tray 5 to slide longitudinally , the sliding directions of the transverse slide rail assembly 2 and the longitudinal slide rail assembly 6 are perpendic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com