Manufacturing method of quick-dry polyester fabric

A production method and polyester technology, applied in the field of polyester production, can solve the problems of poor air permeability, decreased moisture absorption performance, and unlasting moisture absorption effect, and achieve the effects of less layers, good durability, and improved human comfort.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

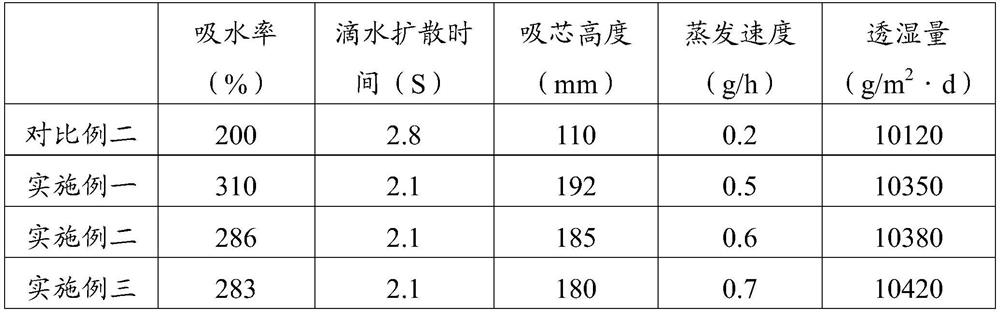

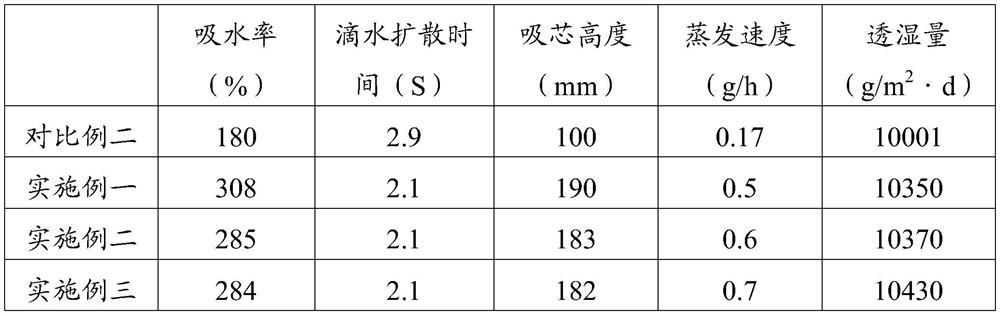

Examples

Embodiment 1

[0034] A method for making a quick-drying polyester fabric, comprising the following steps:

[0035] (1) After mixing 200 parts by weight of organic dibasic acid and 60 parts by weight of dibasic alcohol at 65°C to 70°C, heat up to 190°C for polycondensation;

[0036] (2) Add 10 parts by weight of nano-zinc oxide, 5 parts of titanium dioxide and 0.5 part of 2-hydroxy-4-n-octyloxybenzophenone to the product of polycondensation and mix them at 50°C to 55°C, then mix them at 210°C to Under the temperature condition of 230°C and the vacuum condition of 250Pa~300Pa, the polymerization reaction is carried out again to obtain the copolyester melt;

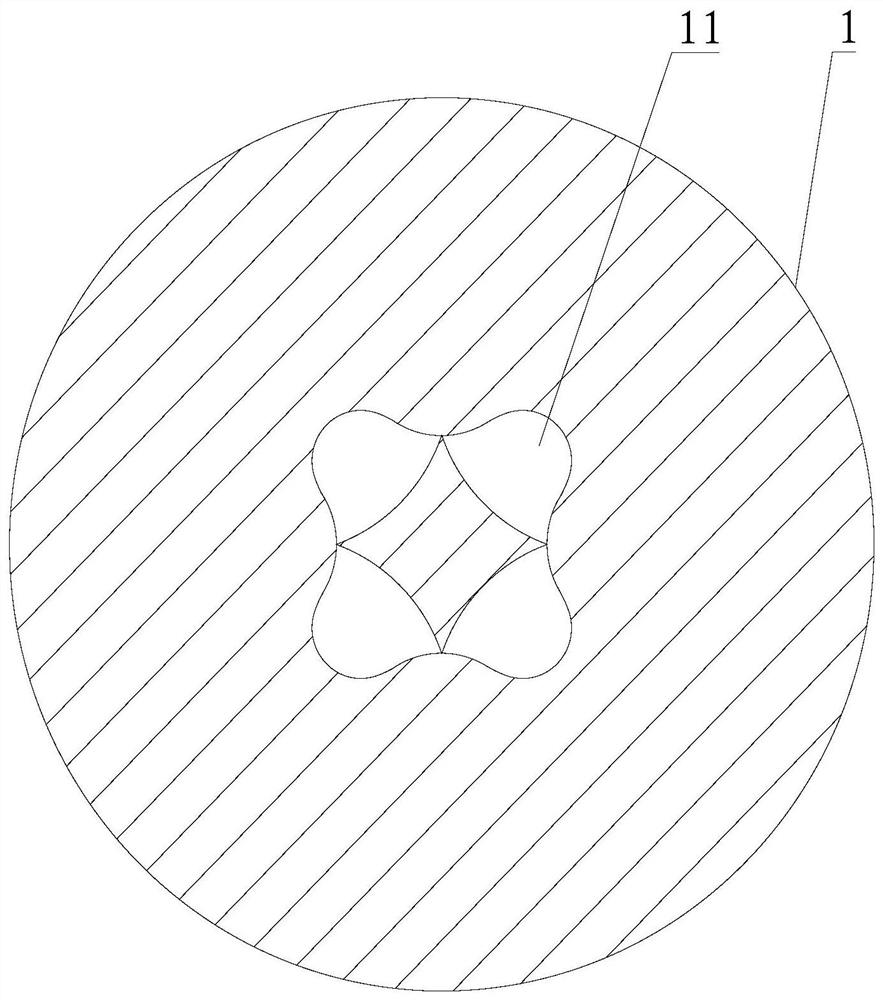

[0037] (3) After the copolyester melt is divided into filaments, it is sprayed through the special-shaped spinneret 1, and the special-shaped polyester filament is sprayed out with a fineness of 0.8dtex. After the spinning is completed, it is blown, oiled and drawn to make a special-shaped filament Polyester filament roll; specifically, ...

Embodiment 2

[0040] A method for making a quick-drying polyester fabric, comprising the following steps:

[0041] (1) After mixing 250 parts by weight of organic dibasic acid and 65 parts by weight of dibasic alcohol at 65°C to 70°C, heat up to 190°C for polycondensation;

[0042] (2) After adding 15 parts by weight of nano-zinc oxide, 7.5 parts by weight of titanium dioxide and 1.5 parts by weight of 2-hydroxy-4-n-octyloxybenzophenone to the finished product of polycondensation and mixing at 50°C to 55°C, Under the temperature condition of ℃~230℃ and the vacuum condition of 250Pa~300Pa, the polymerization reaction is carried out again to obtain the copolyester melt;

[0043] (3) After the copolyester melt is divided into filaments, it is sprayed through the special-shaped spinneret 1, and the special-shaped polyester filaments are sprayed out with a fineness of 0.9dtex. Polyester filament roll; specifically, the special-shaped spinneret 1 includes four spinneret holes 11 arranged symmetr...

Embodiment 3

[0046] A method for making a quick-drying polyester fabric, comprising the following steps:

[0047] (1) After mixing 300 parts by weight of organic dibasic acid and 70 parts by weight of dibasic alcohol at 65 ° C to 70 ° C, the temperature is raised to 190 ° C for polycondensation;

[0048] (2) Add 20 parts by weight of nano-zinc oxide, 15 parts by weight of titanium dioxide and 2.5 parts by weight of 2-hydroxyl-4-n-octyloxybenzophenone to the finished product of polycondensation and mix them at 50°C to 55°C. Under the temperature condition of ℃~230℃ and the vacuum condition of 250Pa~300Pa, the polymerization reaction is carried out again to obtain the copolyester melt;

[0049] (3) After the copolyester melt is separated, it is sprayed through the special-shaped spinneret 1, and the special-shaped polyester filament is sprayed out, and the fineness is 1dtex. After the spinning is completed, the special-shaped polyester is made by blowing, oiling and drafting. Silk roll; spe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com