Patents

Literature

43results about How to "Reduce hierarchy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

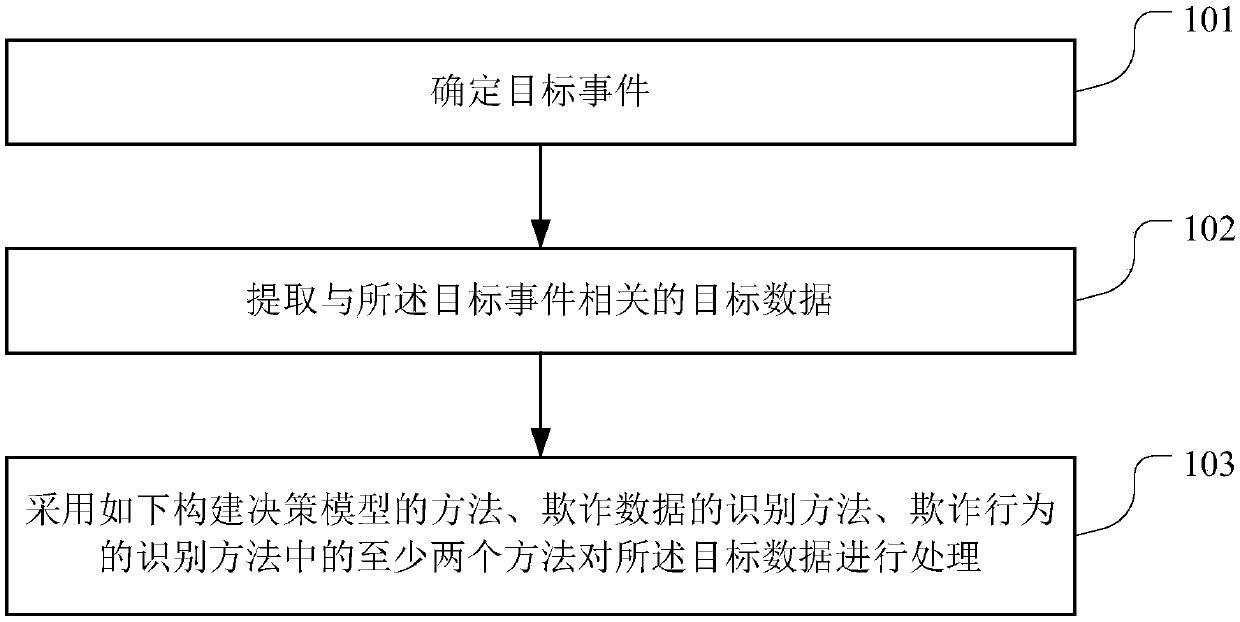

Anti-fraud recognition method, storage medium and server with safe computer

InactiveCN107785058AComprehensive anti-fraud decisionFully identifiableRelational databasesNatural language data processingMedical treatmentDecision-making models

The invention discloses an anti-fraud recognition method used for solving the problem that the anti-fraud capability is insufficient in the medical field. The method provided by the invention comprises the following steps of determining a target event; extracting target data related to the target event; and processing target data by adopting at least two methods of a decision-making model constructing method, a fraud data recognition method and a fraud behavior recognition method. The invention further provides a storage medium and a server with a safe computer.

Owner:PING AN TECH (SHENZHEN) CO LTD

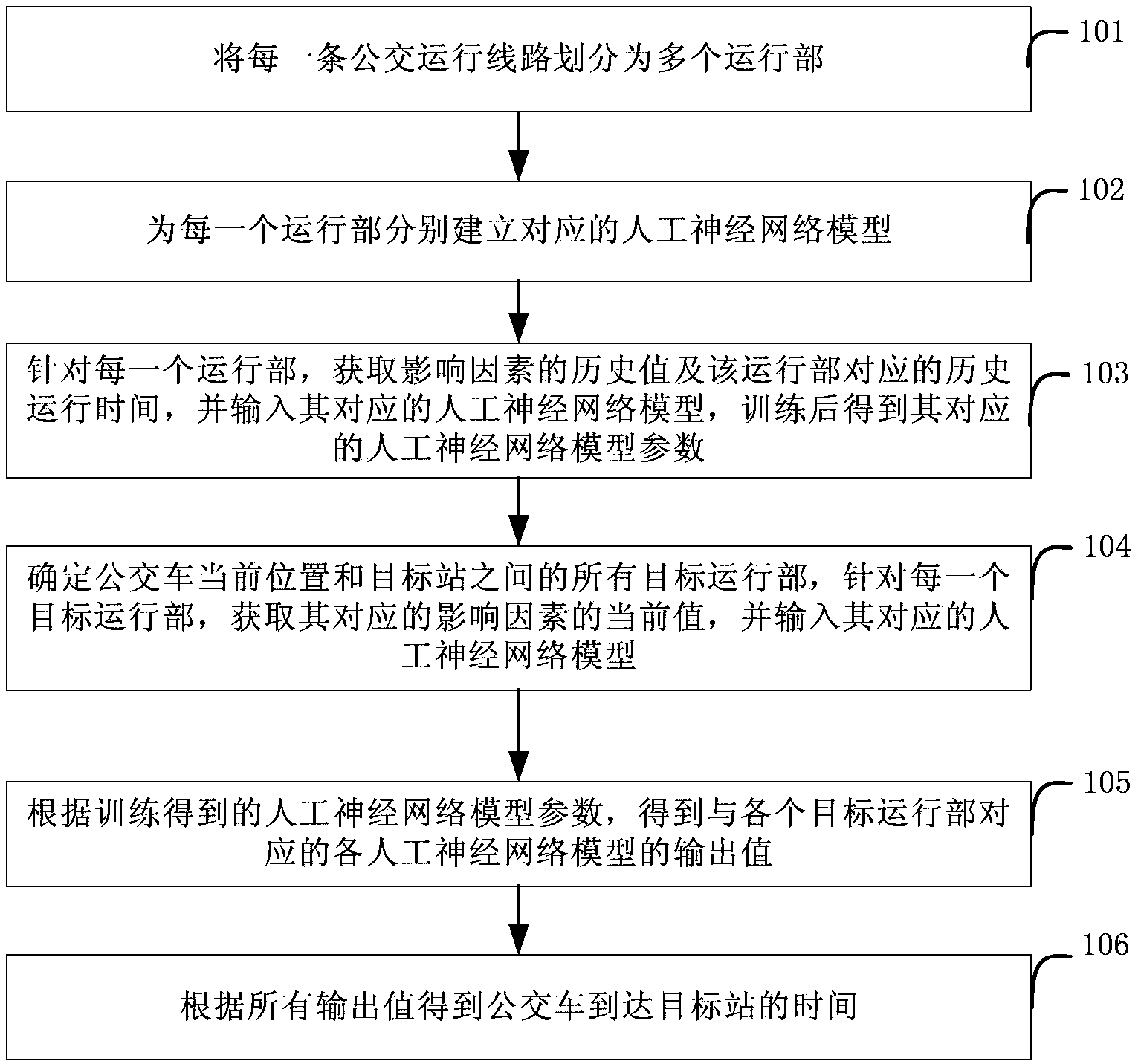

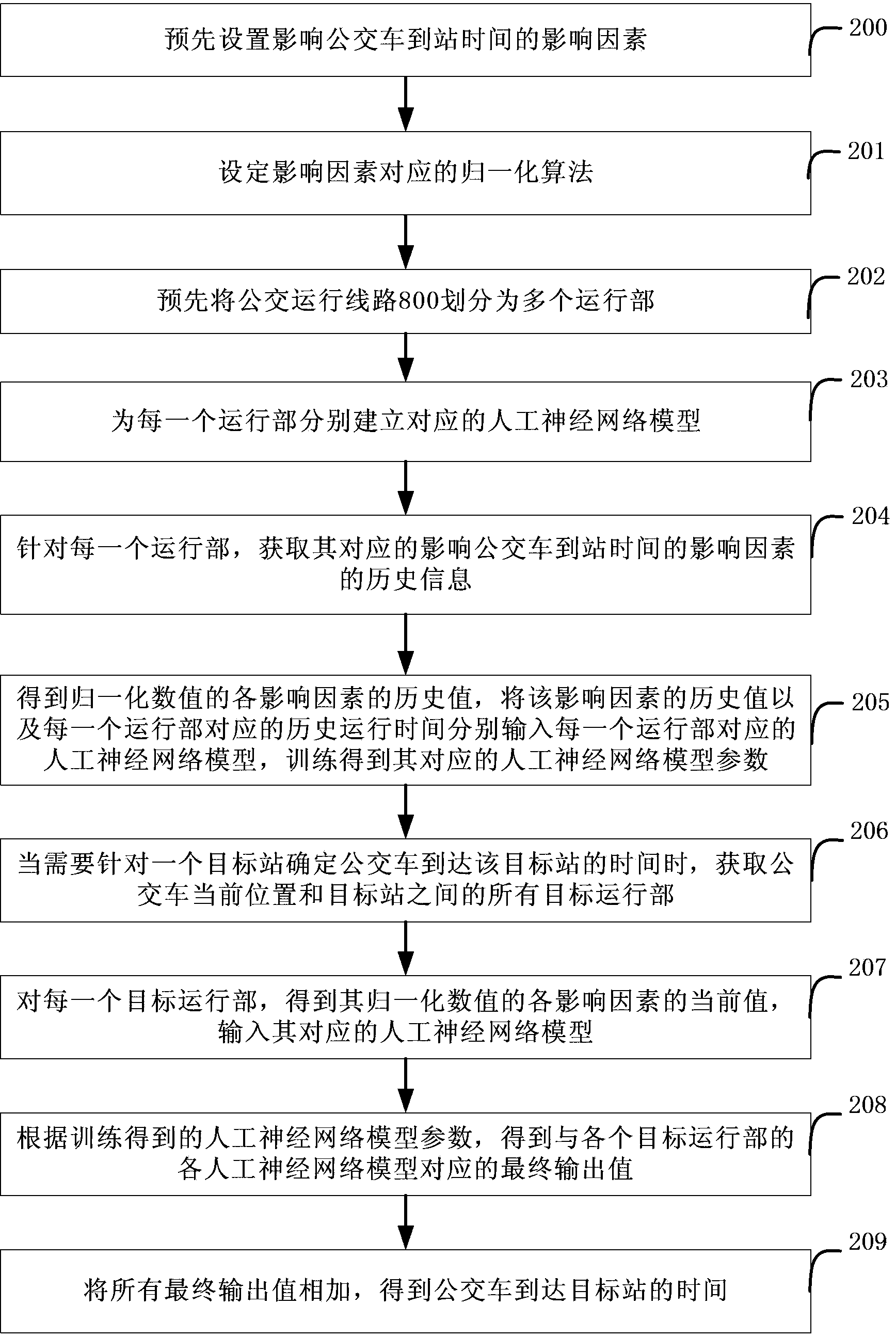

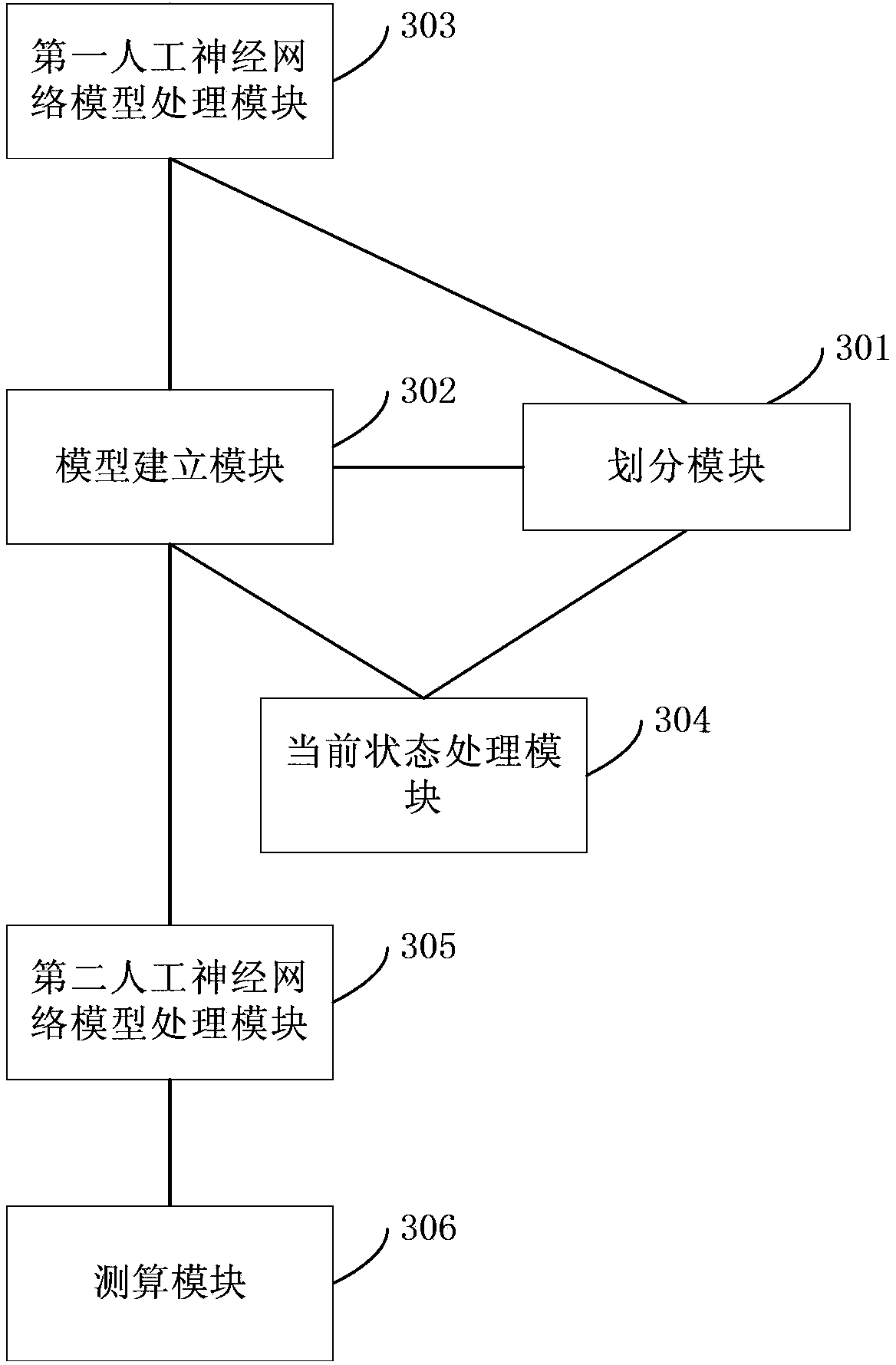

Bus arrival time estimation method and device

InactiveCN104217605AAccurate timeReflect the actual operating conditionsRoad vehicles traffic controlEstimation methodsArrival time

The invention provides a bus arrival time estimation method and device. The method includes dividing each bus running line into a plurality of running portions, and establishing corresponded artificial neural network models respectively; training the running portions to acquire corresponded parameter values of the corresponded artificial neural network models; determining all target running portions between the current bus position and a target station, acquiring current values of the current influence factors corresponding to each target running portion, inputting the corresponded artificial neural network models, acquiring output values of the artificial neural network models corresponded to the target running portions, and acquiring times for the bus arriving the target station according to the output values. The device comprises a dividing module, a model establishing module, a first artificial neural network model processing module, a current state processing module, a second artificial neural network model processing module and a calculating module. By the aid of the method and device, the bus arrival time can be calculated more accurately.

Owner:张伟伟 +1

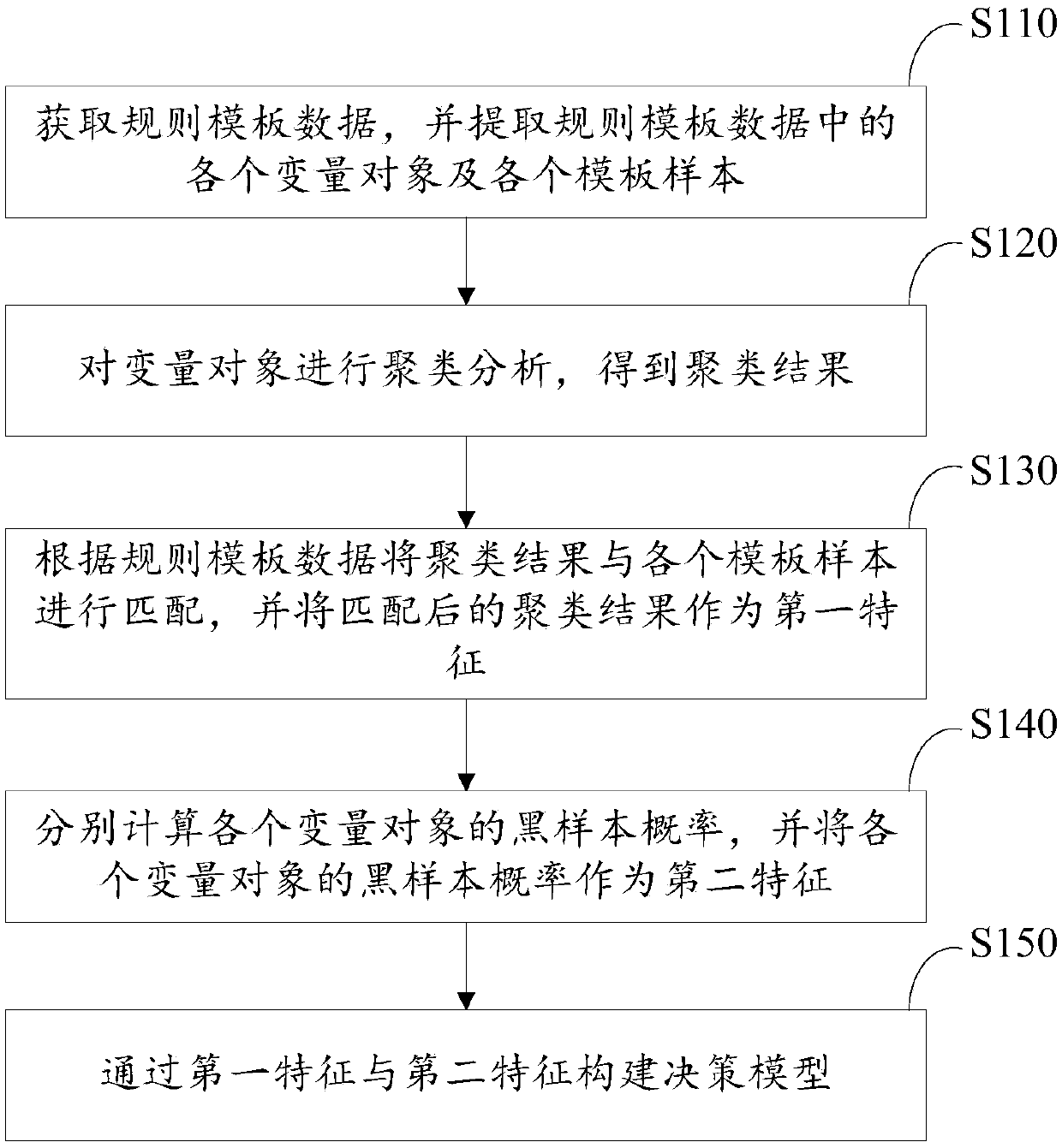

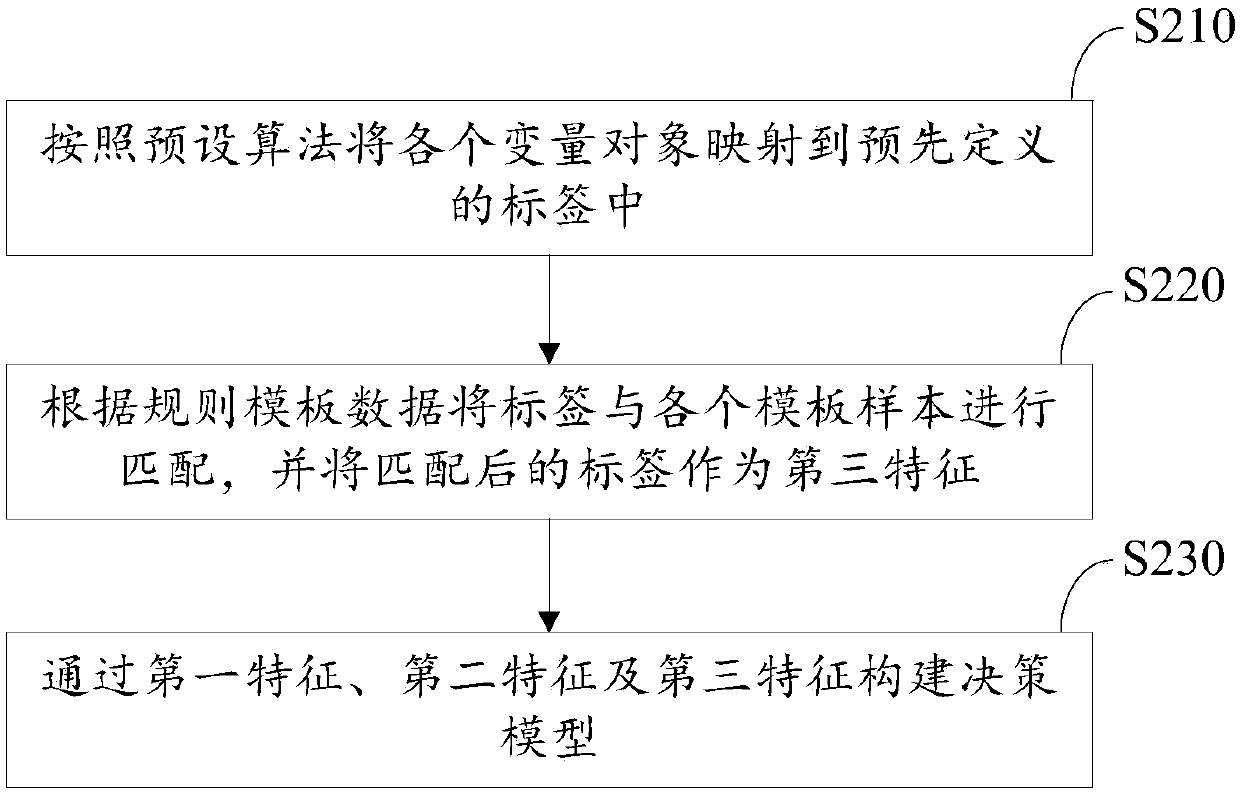

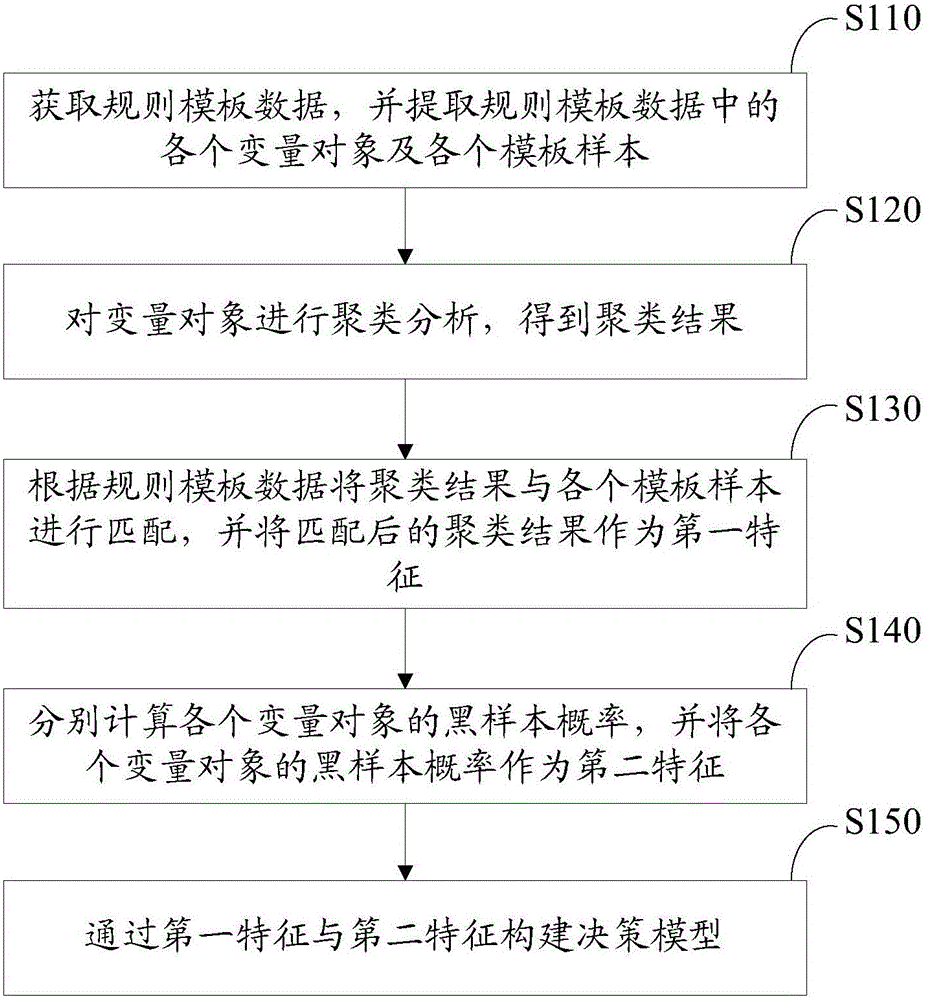

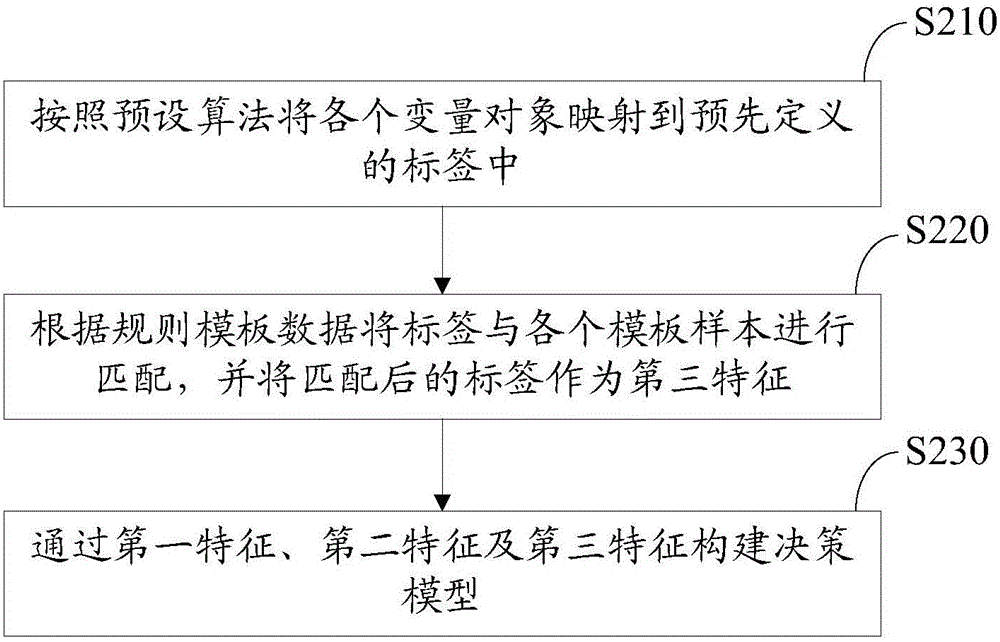

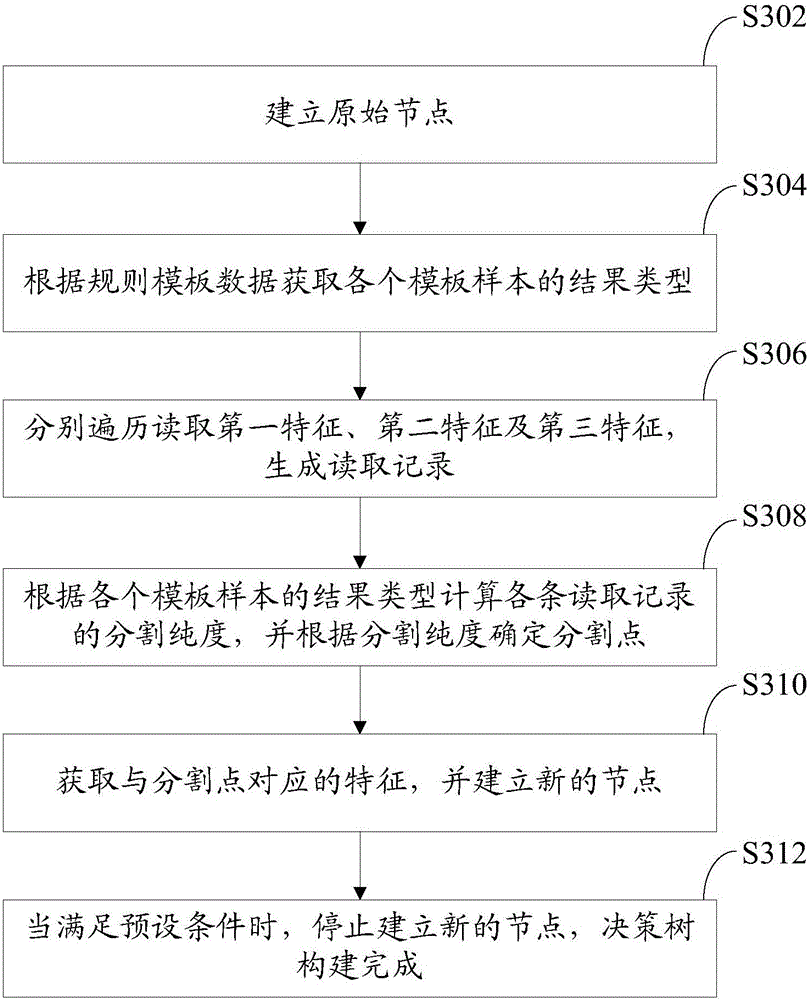

Method and device for building decision-making model

InactiveCN106384282AAccurate performanceReduce dimensionalityFinanceCharacter and pattern recognitionDecision modelCluster result

Owner:PING AN TECH (SHENZHEN) CO LTD

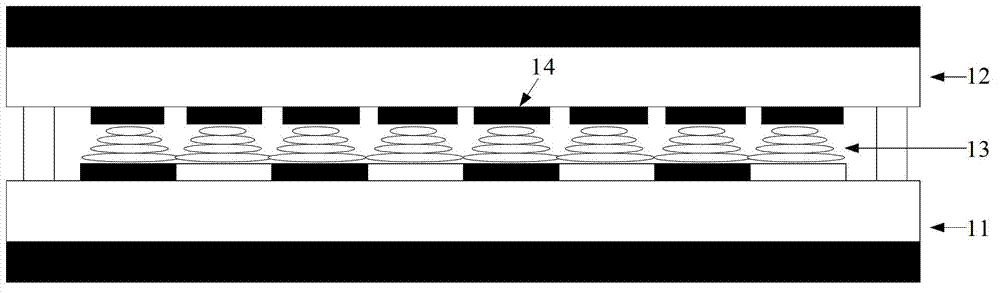

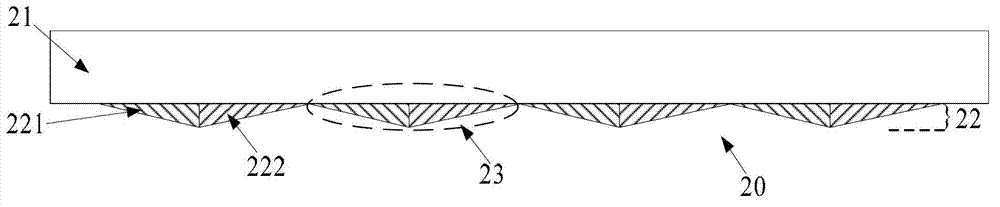

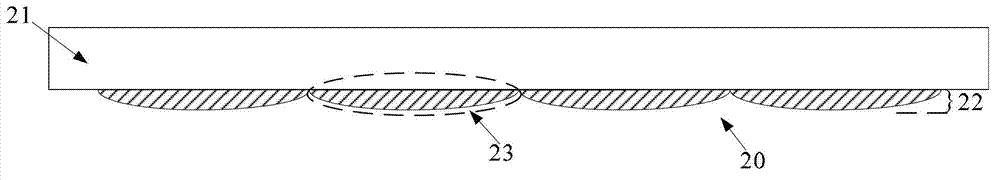

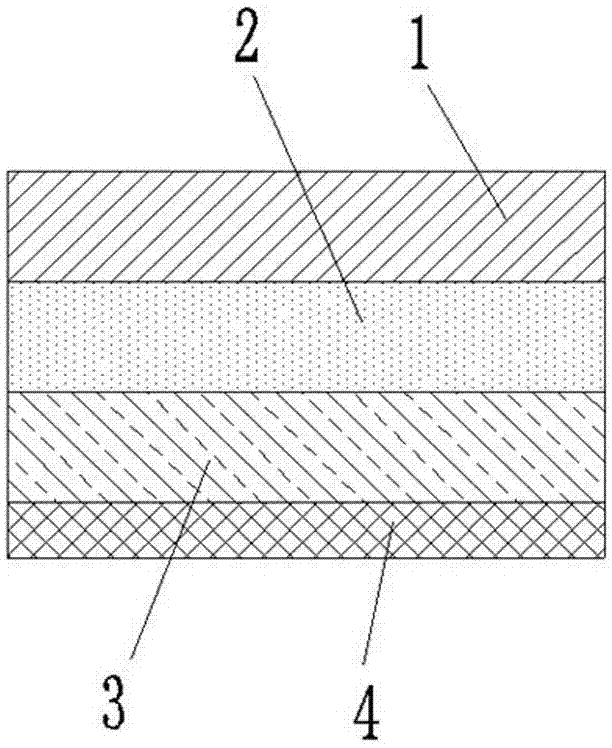

Color film substrate, manufacturing method thereof and display device

ActiveCN102830537AIncrease brightnessReduce complexityNon-linear opticsOptical elementsContinuous lightColor film

The embodiment of the invention provides a color film substrate, a manufacturing method thereof and a display device, which relate to the technical field of display and can be used for increasing the brightness of the display device, reducing the production complexity and the production cost of the display device and reducing the thickness of the display device. The color film substrate comprises a substrate and a color film which is formed on the surface at a light inlet side of the substrate, the color substrate is provided with at least one continuous light refraction structure, the one light refraction structure corresponds to one group of display view field, the group of the display view field comprises a left eye view field and a right eye view field, light emitted by the left eye view field can be emitted into a left eye view area after passing through the light refraction structure corresponding to the left eye view field, and the light emitted by the right eye view field can be emitted into a right eye view area after passing through the light refraction structure corresponding to the right eye view field. The color film substrate disclosed by the embodiment of the invention is used for manufacturing a display.

Owner:BEIJING BOE OPTOELECTRONCIS TECH CO LTD

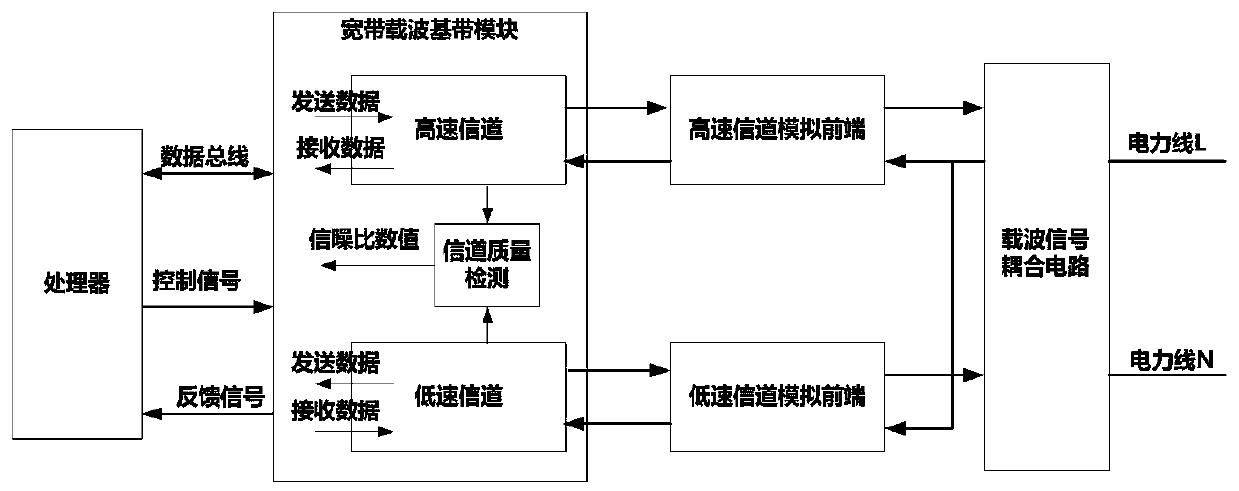

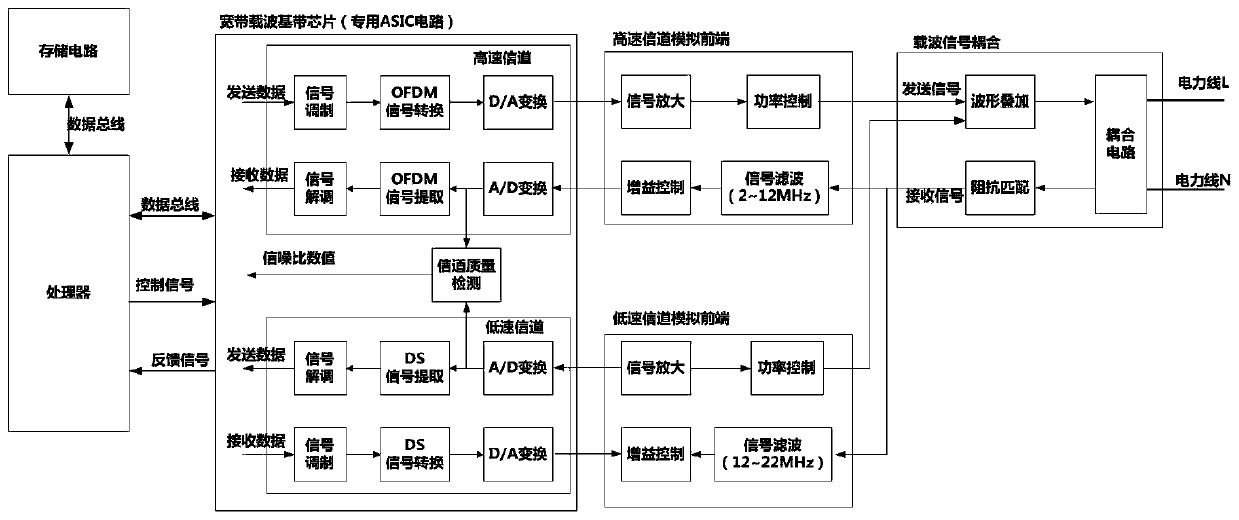

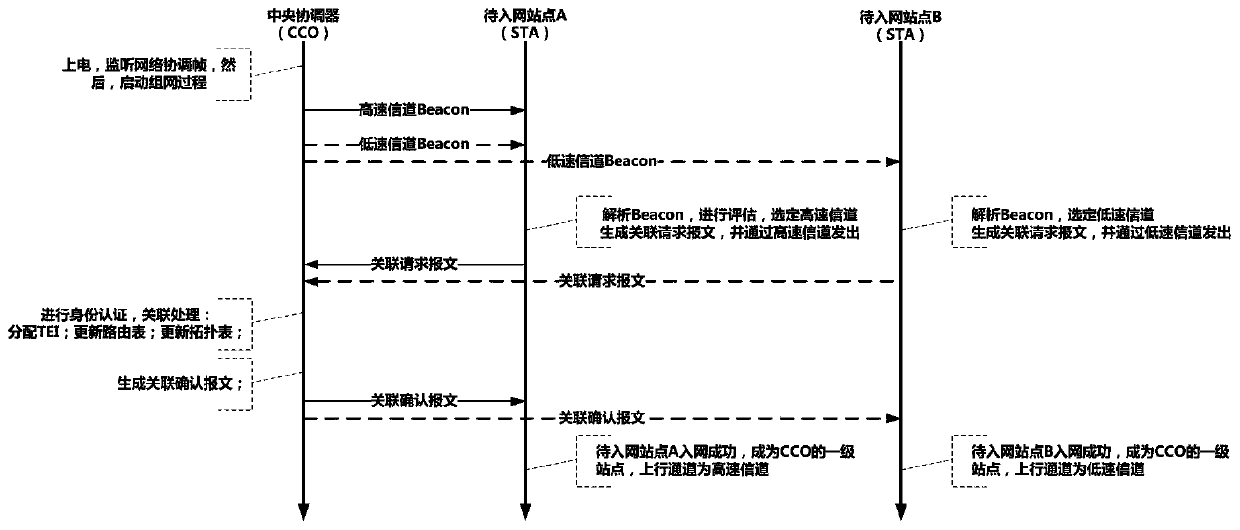

A low-voltage broadband power line carrier communication unit and a networking method

ActiveCN109818780AImprove single-hop transmission distanceAchieve integrationPower distribution line transmissionData switching networksCommunication unitLow speed

The invention relates to a low-voltage broadband power line carrier communication unit and a networking method. The communication unit comprises a processor and a broadband carrier baseband module; The processor realizes a broadband power line carrier communication network protocol stack; The broadband carrier baseband module provides a high-speed channel and a low-speed channel at the same time.the high-speed channel modulates and demodulates a carrier signal by using an OFDM mode; the low-speed channel modulates and demodulates a carrier signal in a direct spread spectrum mode; During networking, a station to be networked selects one channel from a high-speed channel and a low-speed channel of the coordinator as a working channel by taking the channel speed and the channel quality as reference factors, taking the channel speed priority as a principle or taking the channel quality priority as a principle. According to the invention, the network hierarchy is reduced, the one-time communication success rate is improved, and the low-voltage broadband power line carrier transmission efficiency is improved.

Owner:江苏驷源电力有限公司

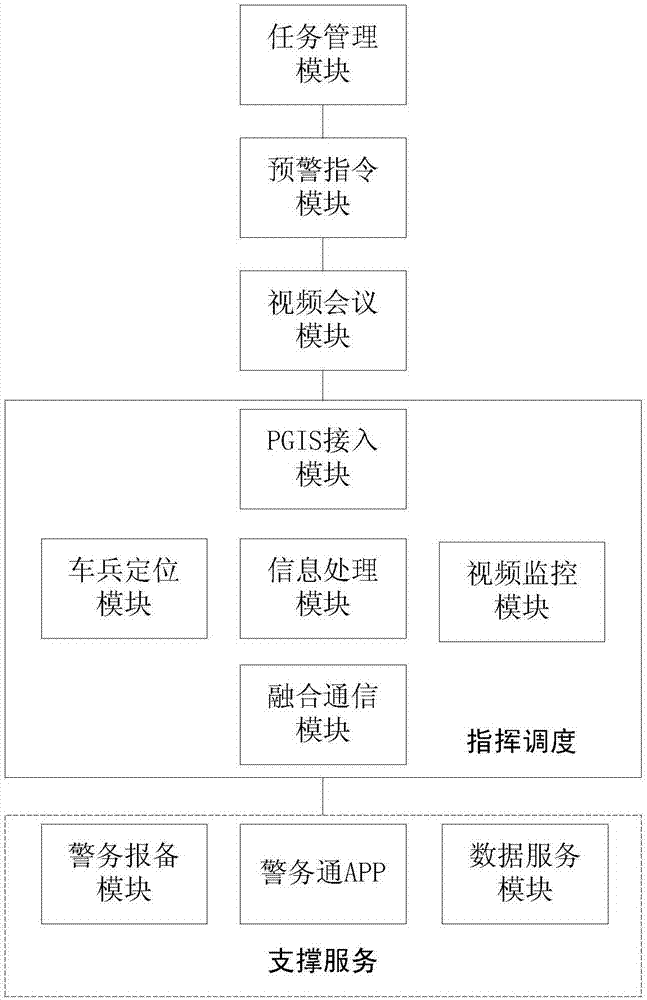

PGIS-based integrated command and dispatching system and method

InactiveCN107547821AReduce HierarchyAccelerateTelevision conference systemsClosed circuit television systemsVideo monitoringPolice reporting

The invention discloses a PGIS-based integrated command and dispatching system and method, and belongs to the technical field of command and dispatching systems. The system comprises a task managementmodule, an early warning instruction module, a video conference module, a PGIS access module, a vehicular soldier positioning module, an information processing module, a video monitoring module, a converged communication module, a police report module and a data service module. By adoption of the PGIS-based integrated command and dispatching system and method disclosed by the invention, in cooperation with the existing PGIS platform, the police APP as well as a variety of video monitoring platforms and voice communication means, the integrated command and dispatching system using the PGIS platform as foundation, using converged communication, vehicular soldier positioning and police APP as means and effectively integrating and accessing a video conference platform, a video monitoring platform, a public security big data platform and a service platform, so as to realize the integration and flatness of command and dispatching and effectively improve the cooperative combat speed and thecommand and dispatching efficiency, and thus is an important improvement to the existing technology.

Owner:HEBEI FAREAST COMM SYST ENG

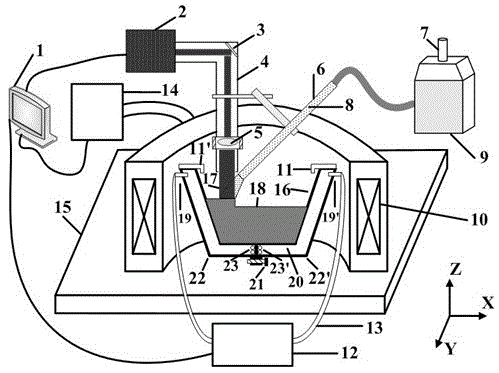

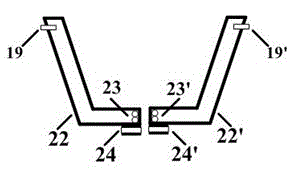

Method for preparing monotectic alloy through casting by combining laser with high-intensity magnetic field

InactiveCN102978427AImprove tissue segregationIncrease hierarchyIncreasing energy efficiencyAlloyCasting mold

The invention relates to a method for preparing a monotectic alloy through casting by combining laser with high-intensity magnetic field, which is characterized by comprising the following steps: mixing the metal powder of all components of the monotectic alloy by mass percent according to the chemical components of the monotectic alloy to prepare the monotectic alloy powder with uniform particle size and good flowability; putting a copper casting mould with a circulating cooling water system in the center position of a high-intensity magnetic field device; and injecting the monotectic alloy powder into a CO2 laser beam heat source by a powder nozzle to melt the monotectic alloy powder quickly, wherein when the laser beam moves away, the molten monotectic alloy powder solidifies in the copper casting mould quickly, and the monotectic alloy is formed. According to the method, when the CO2 laser beam is used to heat and melt the monotectic alloy powder quickly, the high-intensity magnetic field is introduced, thus the convection of the melt is inhibited, the movement speed of the second-phase particles is reduced, and the tissue segregation and the hierarchical structure of the monotectic alloy are improved. Therefore, the method can be used for preparing the monotectic alloy with large size, uniform distribution of second-phase particles and high performance under the condition of high efficiency and low cost, and the problems that the monotectic alloy is hard to cast under the gravitational field condition, has nonuniform tissue distribution and is layered are solved.

Owner:NANCHANG HANGKONG UNIVERSITY

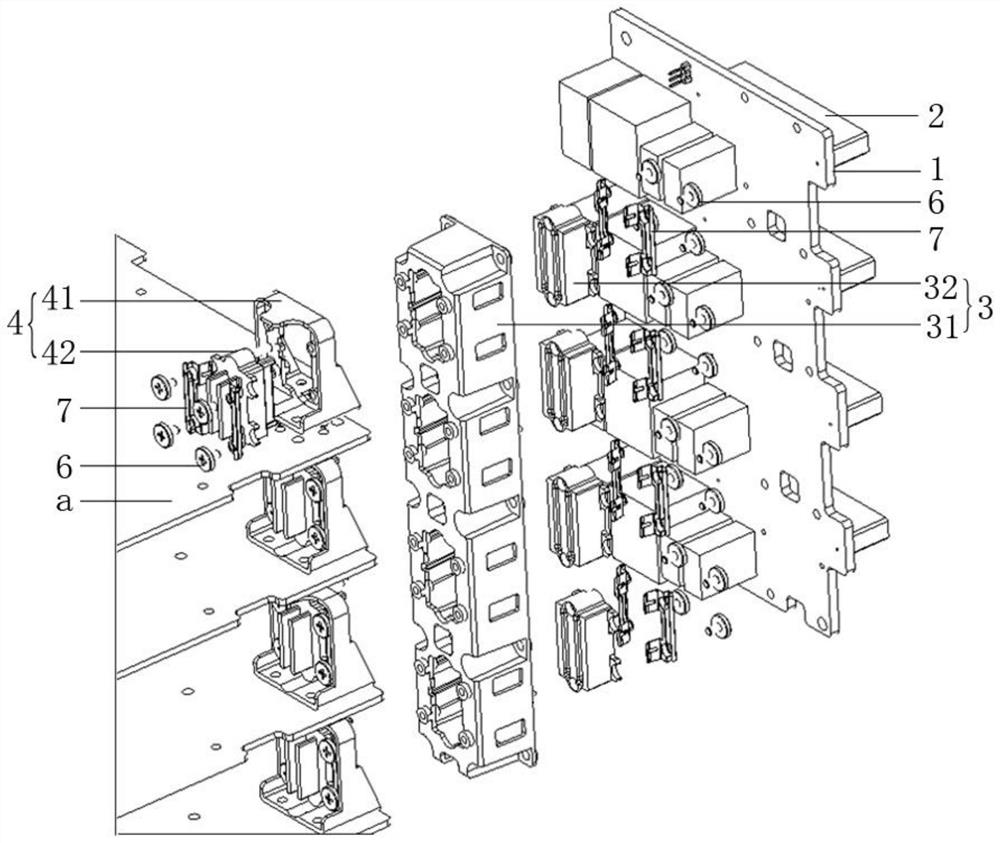

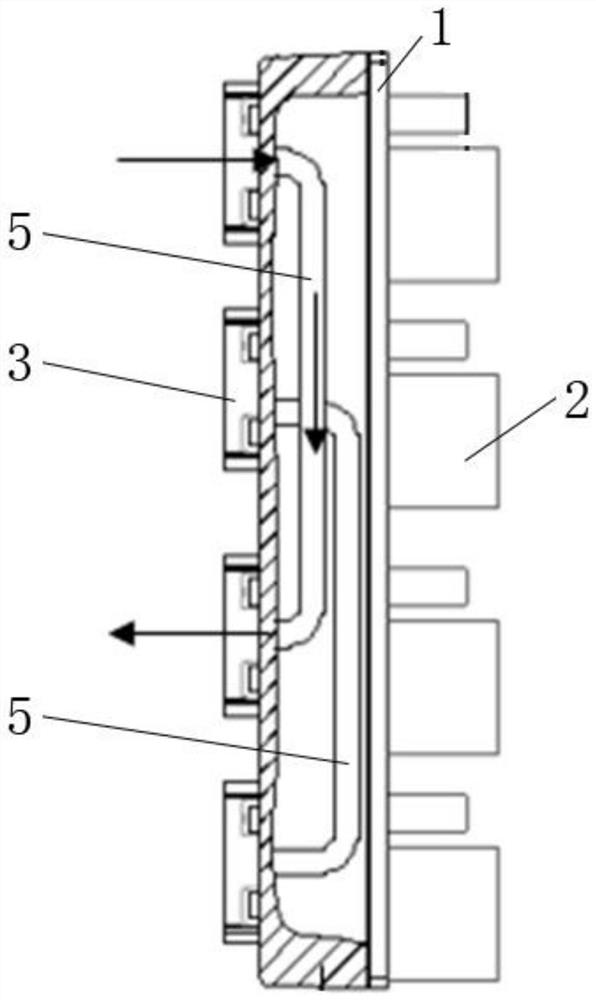

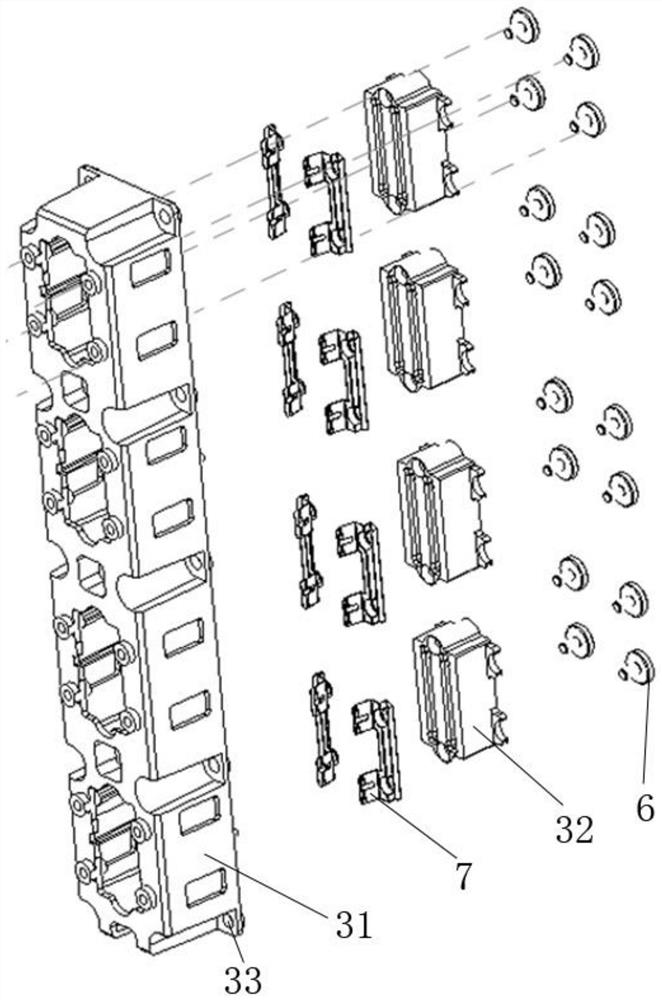

Multi-path server node cross-board signal interconnection device

ActiveCN113067219ASmall installation spaceReduce usageCoupling device detailsTwo-part coupling devicesStructural engineeringInterconnection

The invention discloses a multi-path server node cross-board signal interconnection device which comprises: a middle backboard and a plurality of first signal connectors arranged on the surface of the middle backboard; second signal connectors which are arranged on the back surface of the middle back plate, the distribution areas of the second signal connectors being the same as those of the first signal connectors; signal leading-out ends which are arranged on the node single plates and are used for being connected with the second signal connectors; and a plurality of signal interconnection cables which are connected among the second signal connectors. Therefore, each second signal connector realizes signal transmission on the middle back plate through the signal interconnection cable, and each second signal connector and the first signal connector are arranged in the same area, so that the risk of signal interference is eliminated, the occupied mounting space on the surfaces of the two sides of the middle back plate is saved, and quick disassembly, assembly and maintenance are facilitated; and meanwhile, a signal interconnection path is optimized, a signal link does not need to pass through inter-board transmission of the middle and back boards, and the signal interconnection switching level and loss are reduced.

Owner:SHANDONG YINGXIN COMP TECH CO LTD

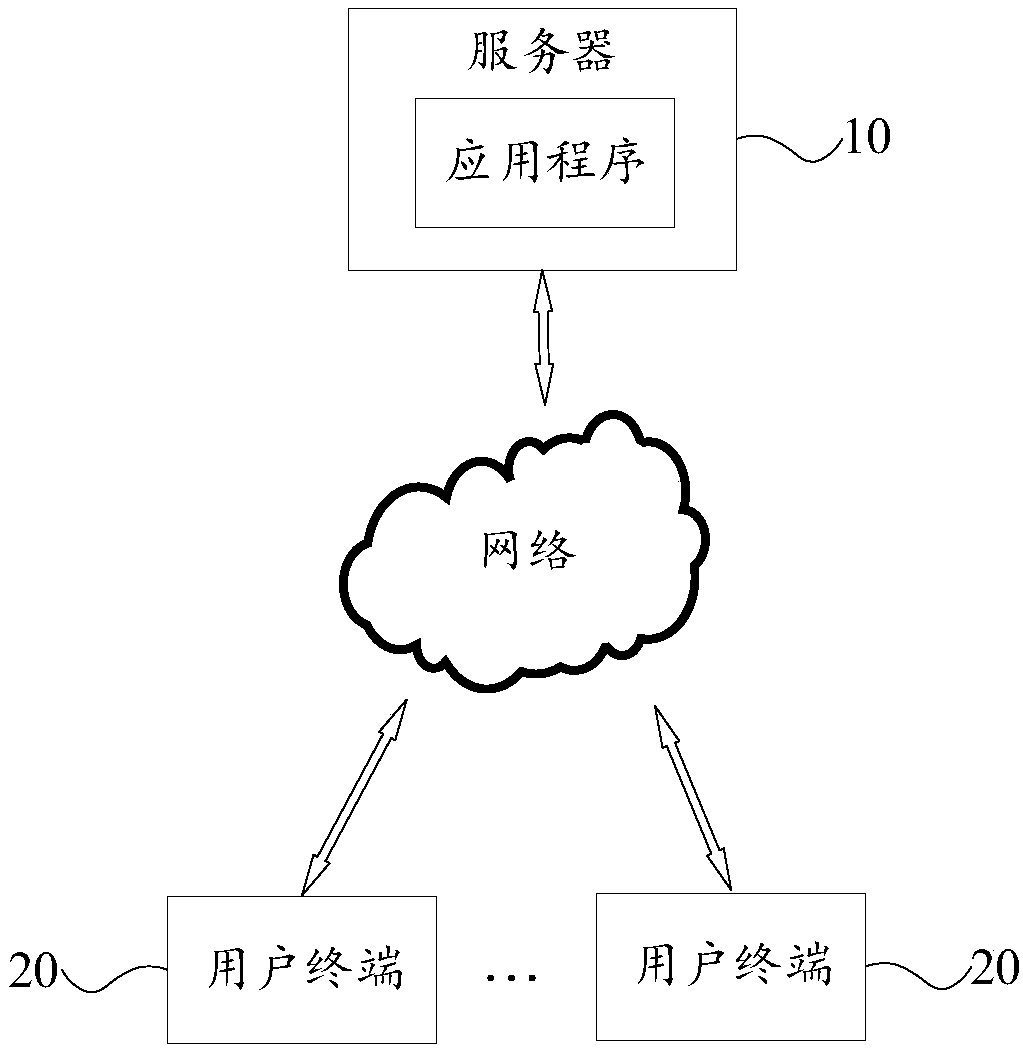

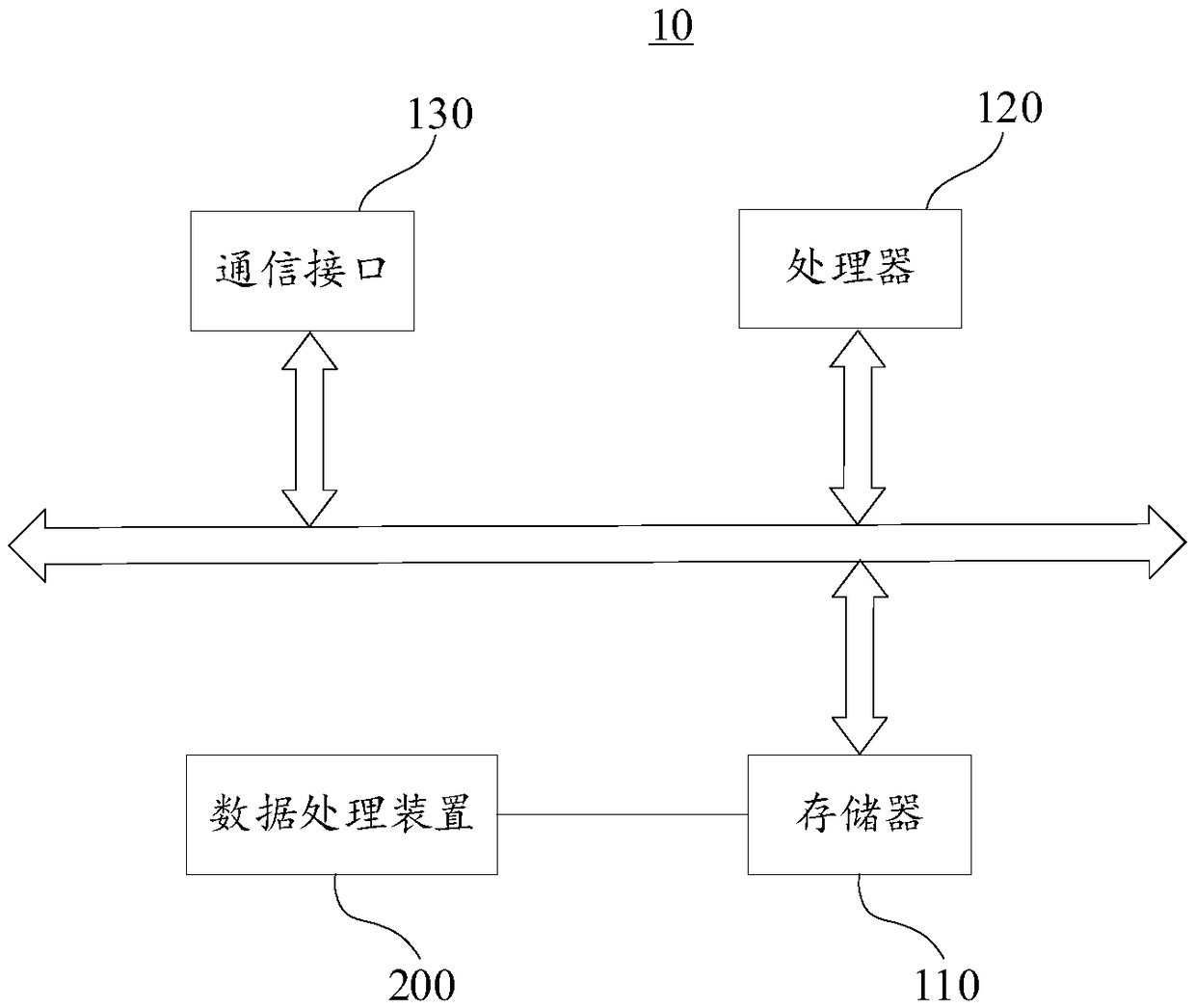

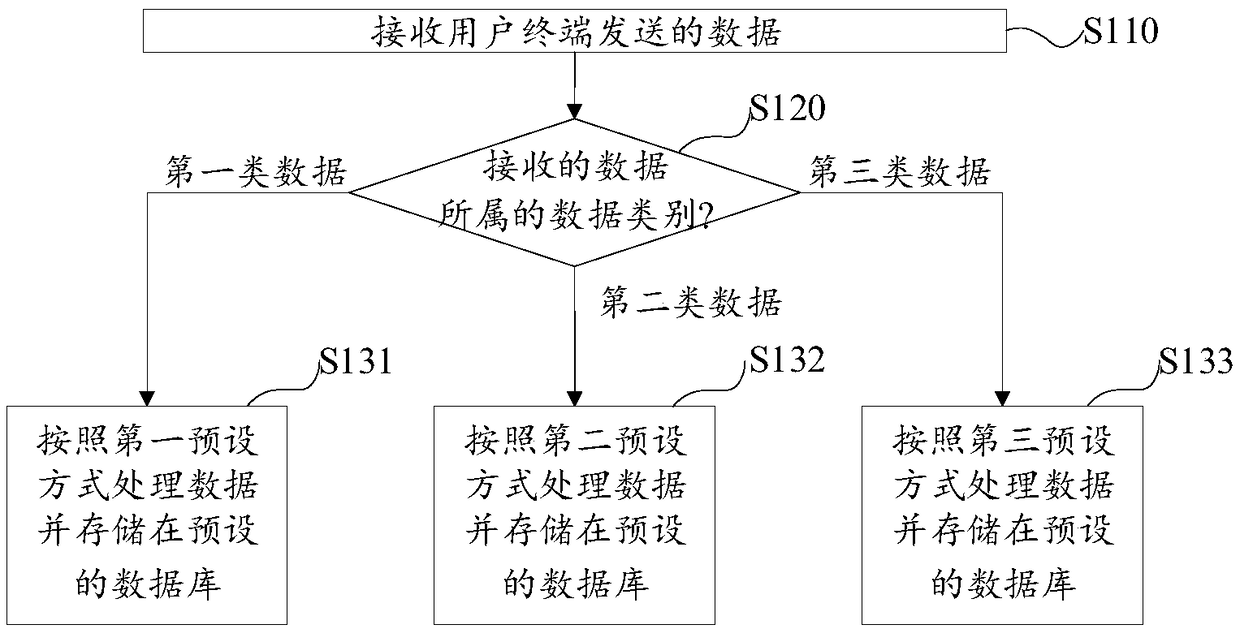

Data processing method and device, server, and readable storage medium

The embodiment of the invention relates to the field of data processing, and provides a data processing method and device, a server, and a readable storage medium. The method comprises the following steps: receiving data sent by a user terminal; determining a data class of the received data; when it is determined that the data is Class-I data, processing the data according to a first preset mode,and storing the processed data in a preset database; when it is determined that the data is Class-II data, processing the data according to a second preset mode, and storing the processed data in a preset database; and when it is determined that the data is Class-III data, processing the data according to a third preset mode, and storing the processed data in a preset database. The data processingmethod and device, the server and the readable storage medium provided by the embodiment of the invention have the advantages that hierarchical relationships among enterprise data units can be reduced, repeated acquisition and processing of identical data on different nodes can be prevented, data circulation nodes can be simplified, information islands can be avoided, the data flow speed can be improved, and fewer operation and maintenance fault points can be achieved.

Owner:INNER MONGOLIA YITAI COAL

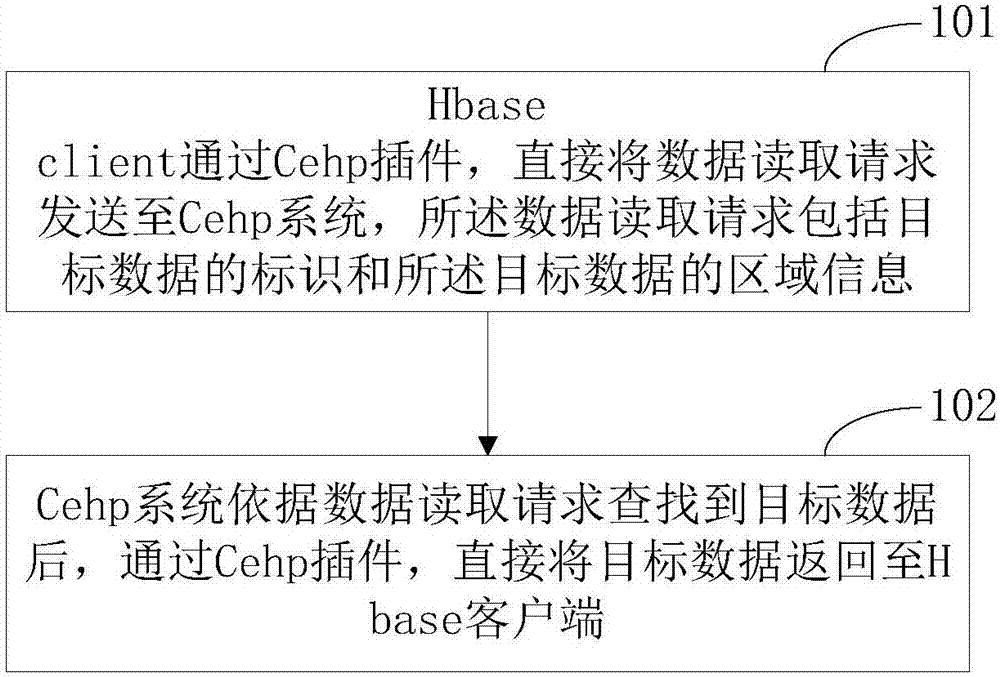

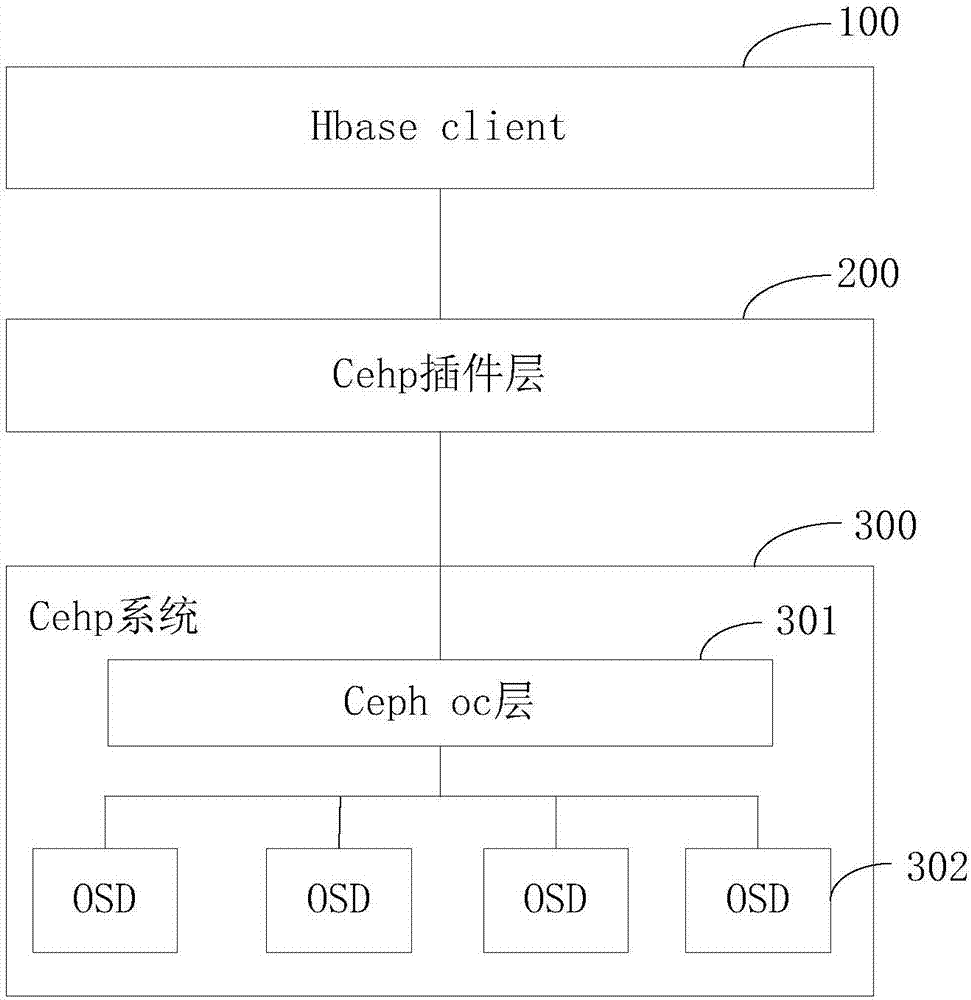

Method and system for data reading

The invention provides a method and system for data reading. The method comprises the steps that an Hbase client terminal directly sends a data reading request to a Cehp system through a Cehp plug-in, wherein the data reading request comprises identification of target data and zone information of the target data; after finding the target data according to the data reading request, the Cehp plug-in directly returns the target data to the Hbase client terminal. According to the method and system for data reading, no cache is disposed in a Cehp plug-in layer, which reduces layers of data reading and omits a process of searching for the target data in the cache of the Cehp plug-in layer, and therefore the data reading efficiency is improved compared with the prior art.

Owner:ZHENGZHOU YUNHAI INFORMATION TECH CO LTD

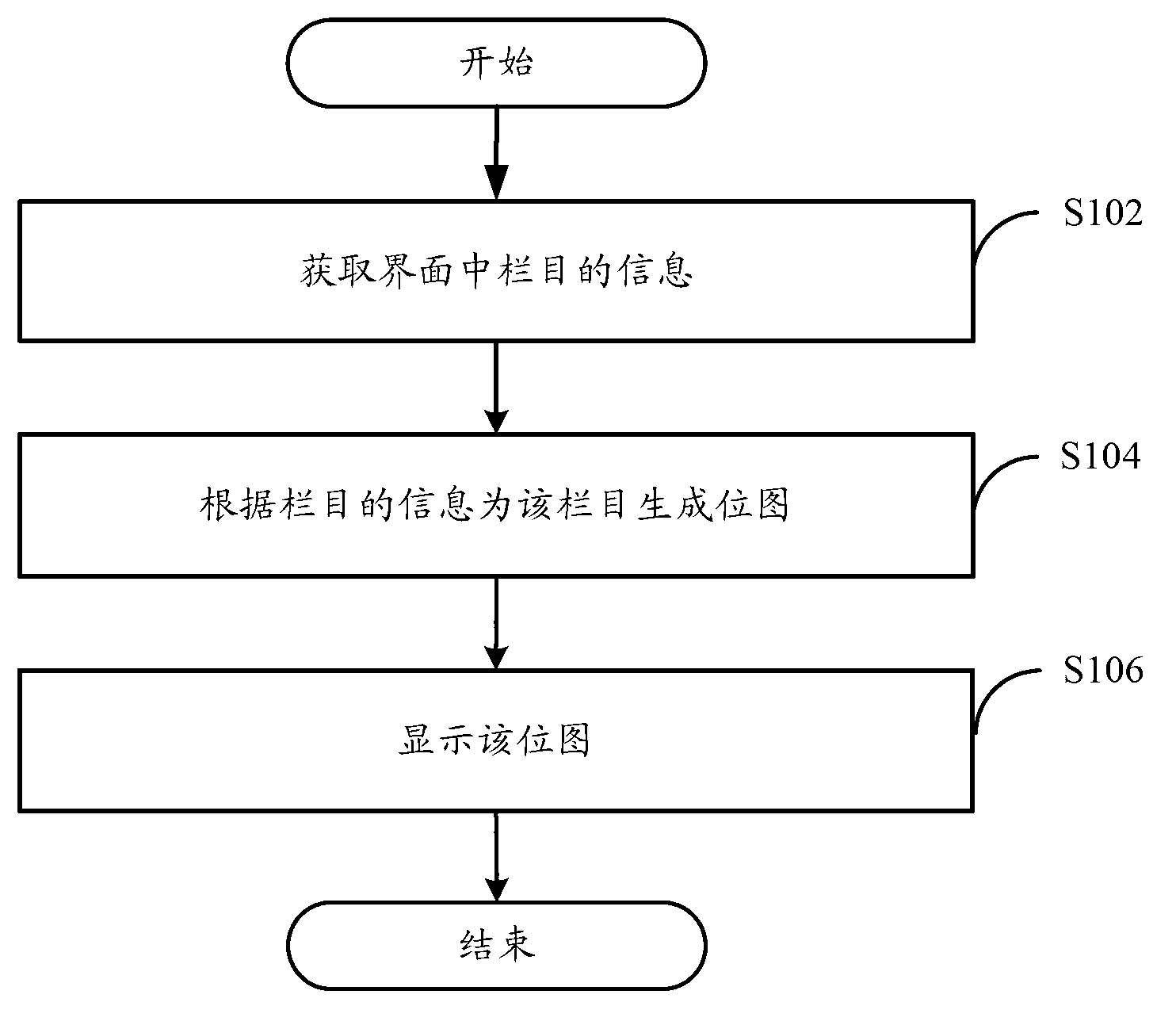

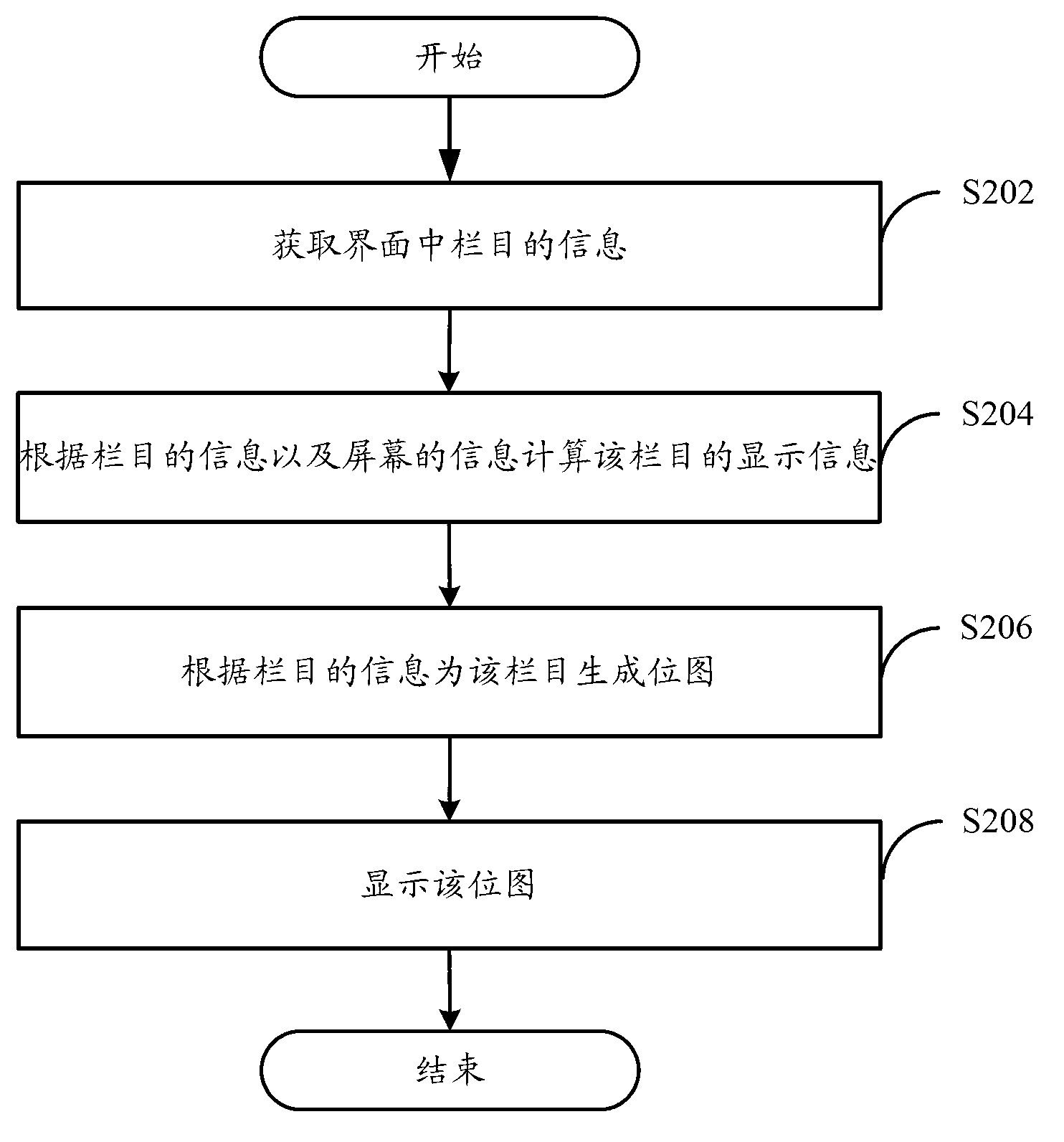

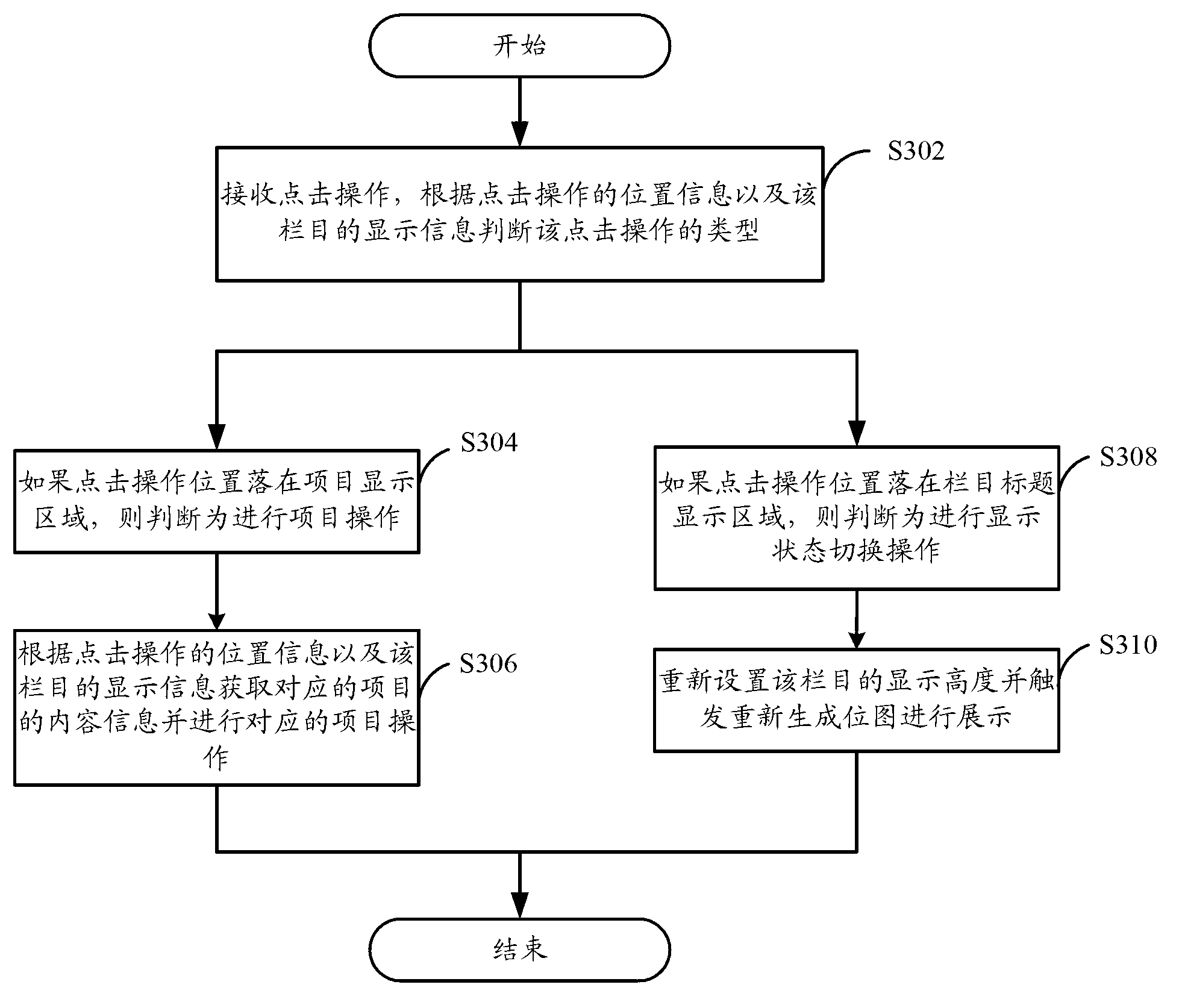

Interface realizing method and interface realizing system

The invention discloses an interface realizing method and an interface realizing system. The method includes acquiring information of columns in an interface, generating bitmaps for the columns according to the information of the columns and displaying the bitmaps. By the interface realizing method and the interface realizing system, the technical effects of reduction of hierarchical structures for interface displaying and improvement of interface operation smoothness are realized.

Owner:BEIJING QIHOO TECH CO LTD +1

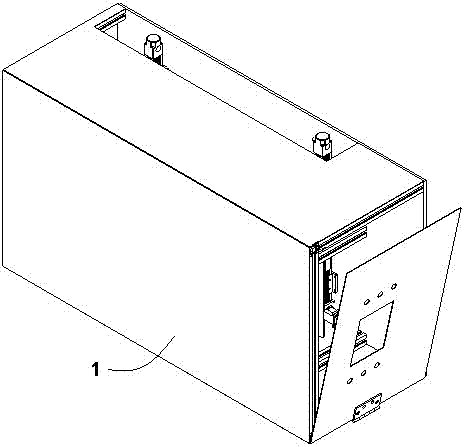

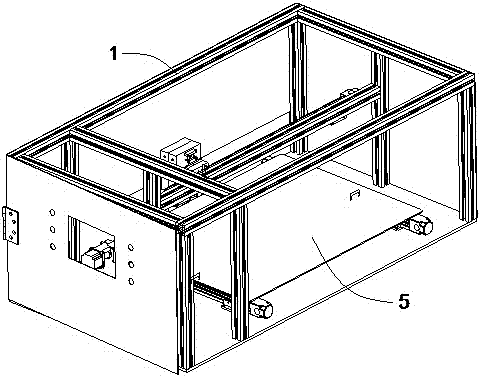

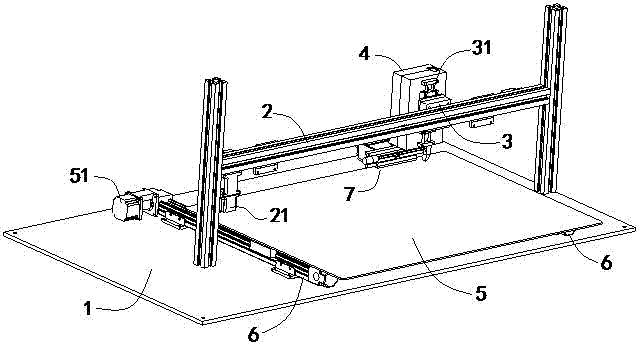

Woodwork nail-shooting processing robot

InactiveCN107309987AReduce hierarchyReduce jitterStapling toolsManipulatorOperational stabilityMechanical engineering

The invention discloses a woodwork nail-shooting processing robot. The robot comprises a rack. A horizontally-arranged transverse sliding rail assembly is arranged on the rack, and is provided with a lifting platform capable of sliding in the transverse direction and a transverse driver used for driving the lifting platform to slide in the transverse direction. The lifting platform is provided with a nail gun module capable of sliding in the vertical direction and a vertical driver used for driving the nail gun module to slide in the vertical direction. A woodwork sliding tray is arranged at the bottom of the rack. A longitudinal sliding rail assembly is arranged between the rack and the woodwork sliding tray. The rack is provided with a longitudinal driver used for driving the woodwork sliding tray to slide in the longitudinal direction. The sliding direction of the transverse sliding rail assembly is perpendicular to that of the longitudinal sliding rail assembly. According to the woodwork nail-shooting processing robot, shaking of the nail gun module can be reduced when the nail gun module is operated, and the woodwork nail-shooting processing robot has the advantages of being good in operation stability, good in anti-shaking performance, high in positioning precision, high in processing speed, simple in structure and low in manufacturing cost.

Owner:塞伯睿机器人技术(南京)有限公司

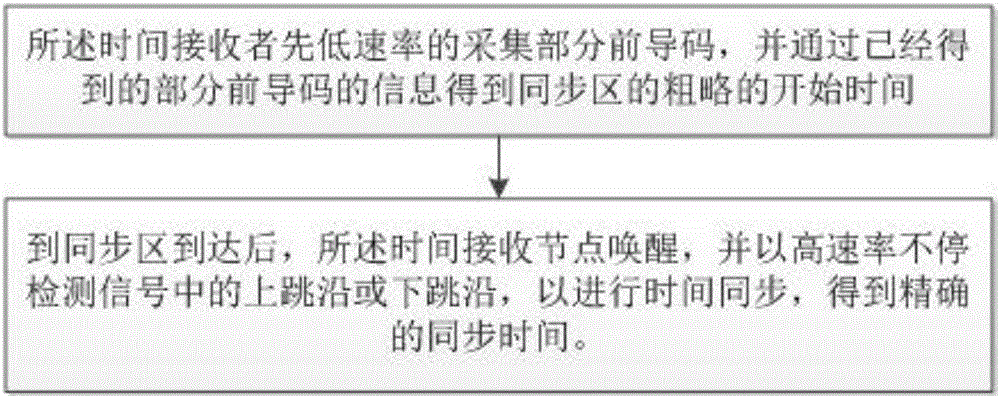

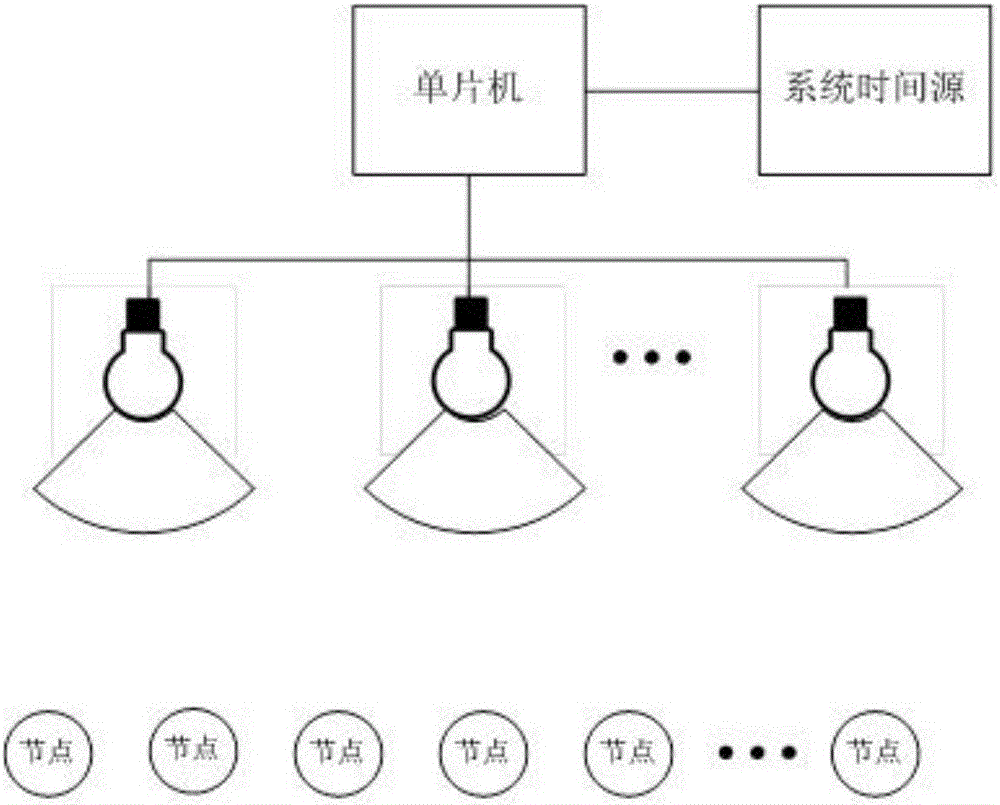

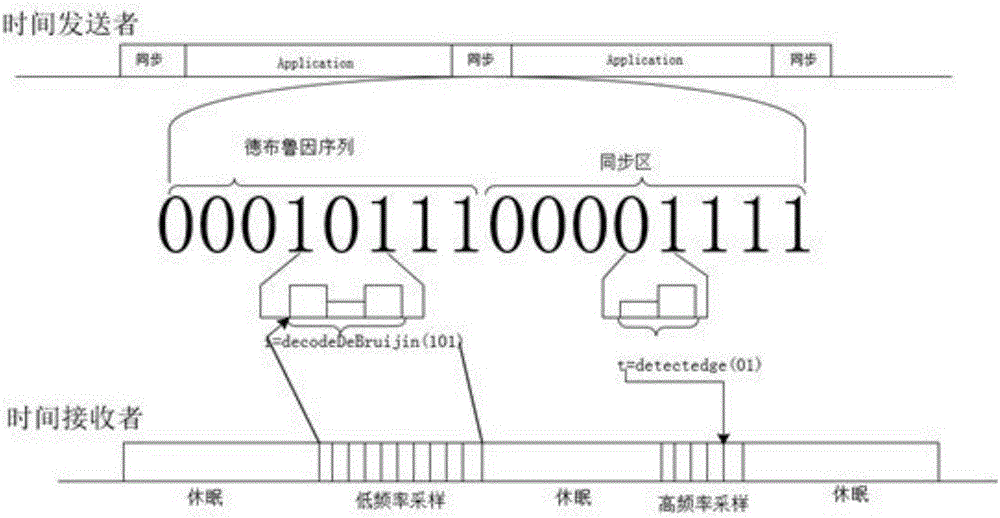

Time synchronization method and system for wire1ess sensor network

InactiveCN106059699AReduce hierarchyHigh synchronization accuracyPower managementNetwork topologiesTime informationTime segment

The invention discloses a time synchronization method and system for a wire1ess sensor network. A time sender informs a time receiver of time information about the position of a time synchronization point via visible light communication, and the time receiver performs time synchronization using the received time synchronization point; the time synchronization point is a hop-up edge or a hop-down edge within a specific time period in sent signals, the specific time period is a synchronization zone, and the synchronization zone has only one hop-up edge or hop-down edge for indicating the time synchronization point. According to the time synchronization method based on visible light communication, all sensor nodes can directly perform time synchronization on a visible light source, so that the levels of the tree structure of the original synchronization method are reduced and the synchronization precision is improved. Each time synchronization is not limited by the maximum amplitude in the absence of a tree clock topology, so that the time required by the time synchronization process is effectively reduced.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

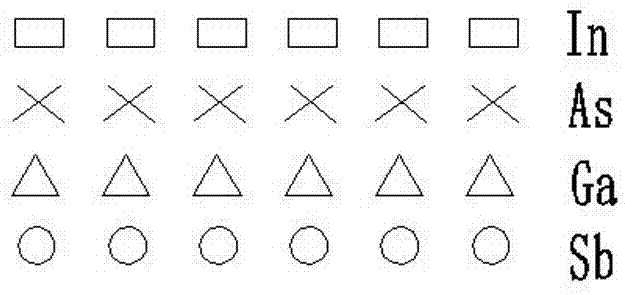

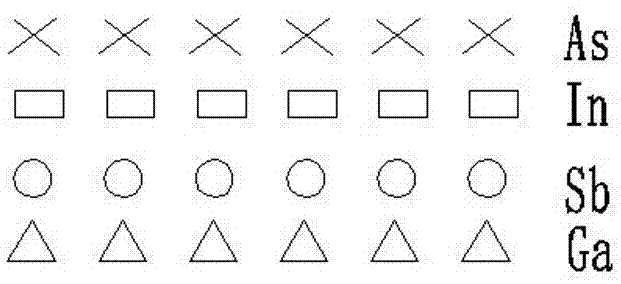

Method for improving cut-off wavelength of indium arsenide/gallium antimony superlattice infrared detector material, indium arsenide/gallium antimony type II superlattice and application thereof

ActiveCN107393982AImprove the detection rateReduce generation difficultyFinal product manufacturePhotovoltaic energy generationIndiumPhysical chemistry

The invention aims to provide a method for improving a cut-off wavelength of an indium arsenide / gallium antimony superlattice infrared detector material, an indium arsenide / gallium antimony type II superlattice material and an application thereof aiming at the defects that the growth difficulty of the material is increased, the growth cost of the material is high, and the service life of production equipment is short due to excessive intracrystalline interfaces of indium arsenide / gallium antimony type II superlattices in the prior art. According to the method for improving the cut-off wavelength of the indium arsenide / gallium antimony superlattice infrared detector material, the cut-off wavelength of the indium arsenide / gallium antimony type II superlattice infrared detector material can be increased by increasing the stress of an InSb layer in an indium arsenide / gallium antimony type II superlattice unit cell and changing the energy band structure of the superlattice material. By adopting the method provided by the invention, the cut-off wavelength of the superlattice infrared detector material can be increased by changing the energy band structure, obtained devices prepared from the indium arsenide / gallium antimony type II superlattice material has higher detectivity, the number of material interfaces can be reduced, the levels can be reduced, and the detection wavelength and detectivity of the indium arsenide / gallium antimony type II superlattice material can be further increased.

Owner:秦皇岛博硕光电设备股份有限公司

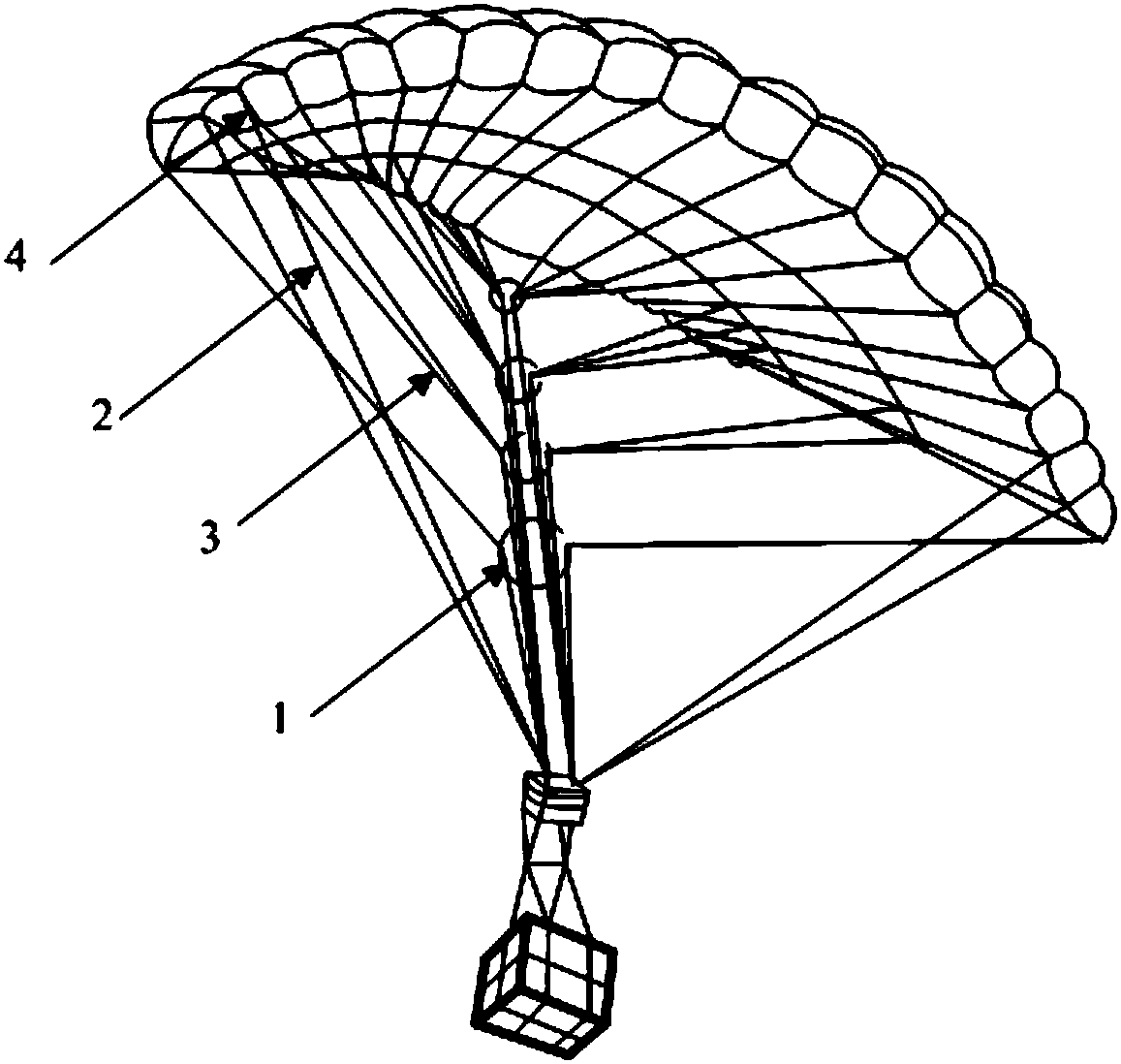

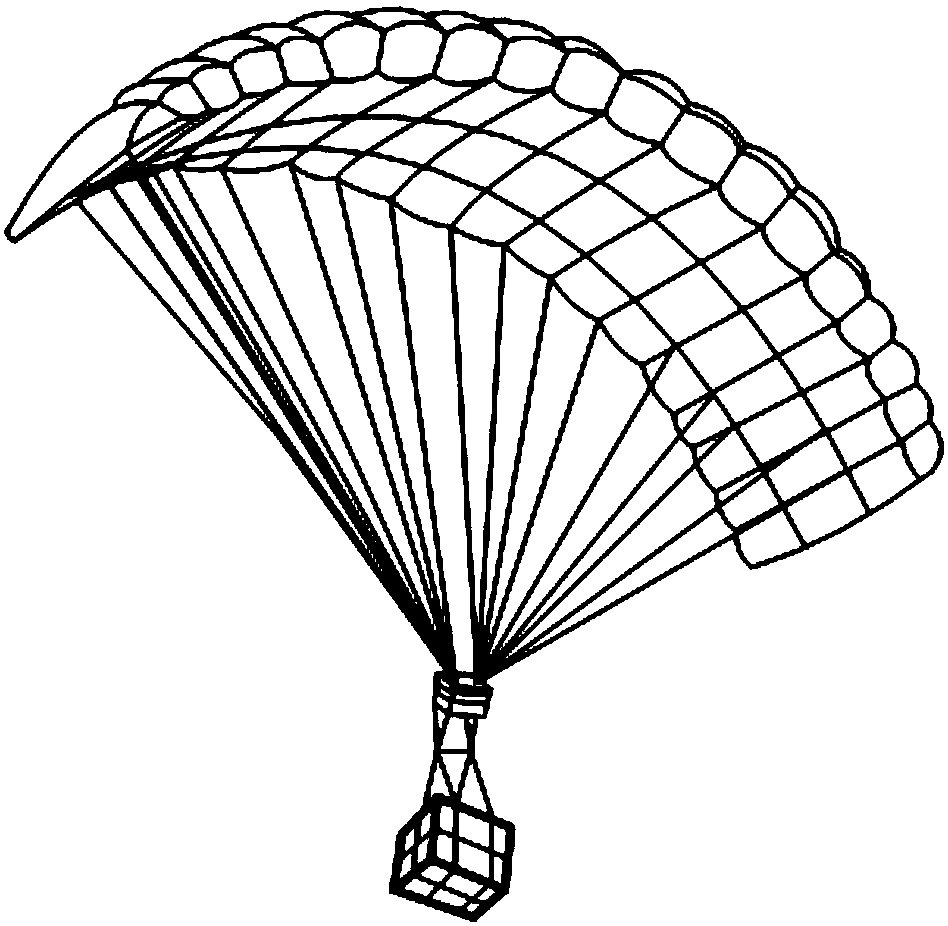

Method for reducing opening shock of ram air parachute

ActiveCN107826256ADoes not affect the use of packagingReduce hierarchyParachutesFront edgeTrailing edge

The invention relates to a method for reducing the opening shock of a ram air parachute. The method for reducing the opening shock of the ram air parachute comprises the following steps that an air inlet parachute cord at the front edge of the ram air parachute is used as a non-bundled parachute cord and the rest parachute cords of the ram air parachute are used as bundled parachute cords; the bundled parachute cords are divided into a plurality of groups in sequence from the rear edge of the ram air parachute to the front edge of the ram air parachute, wherein the parachute cords in each group are symmetric relative to the center of the airfoil of the ram air parachute; the parachute cords in each group are bundled and tightened together by using a binding rope and the binding point is atthe center of the airfoil; the positions of all binding points move down in sequence from the rear edge to the front edge; the strengths of all binding ropes are reduced in sequence from the rear edge to the front edge; when the ram air parachute is unfolded, an air chamber is unfolded to be inflated from the front edge and the rear edge under the driving of the non-bundled air inlet parachute cord; in the inflating process, the parachute cords, which are tensioned in sequence from the front edge to the rear edge, are enabled to snap the binding ropes in sequence from bottom to top; and meanwhile, the air chamber is gradually inflated until the air chamber is full of air. According to the method for reducing the opening shock of the ram air parachute, sliding cloth does not need to be closed up because the ram air parachute is unfolded step by step, the layer level of the parachute system can be reduced, and the implementation is simple.

Owner:AEROSPACE LIFE SUPPORT IND LTD

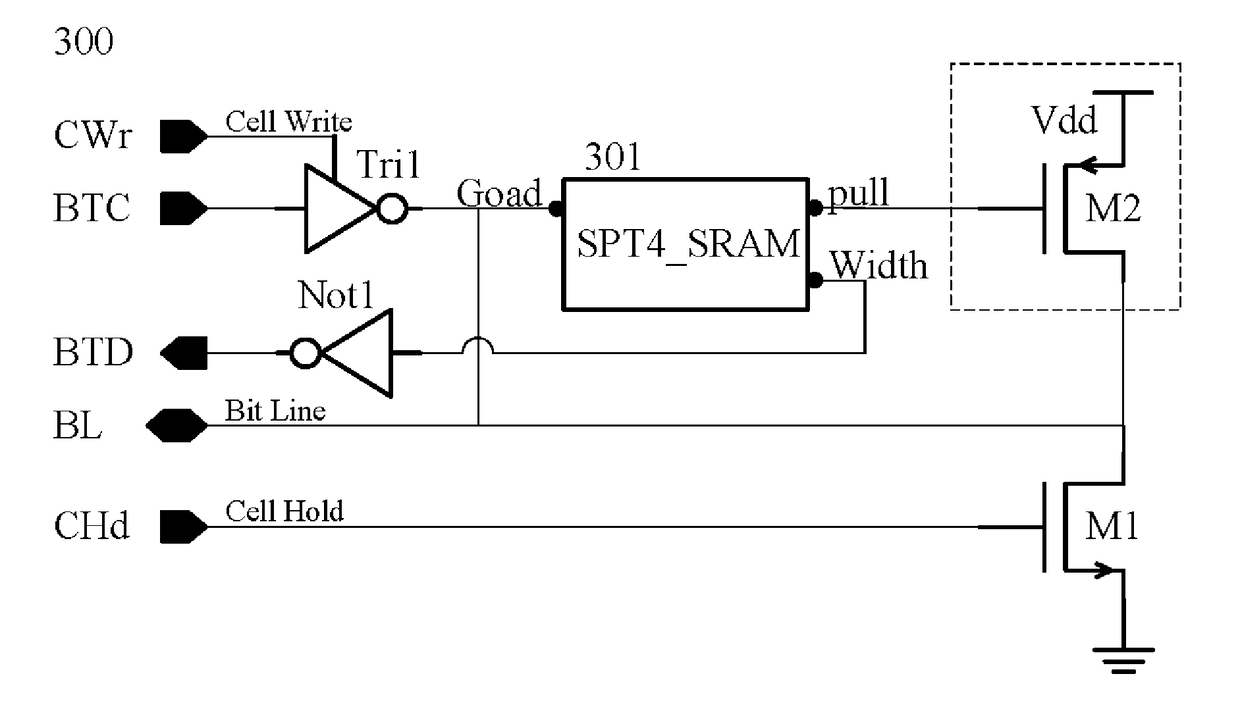

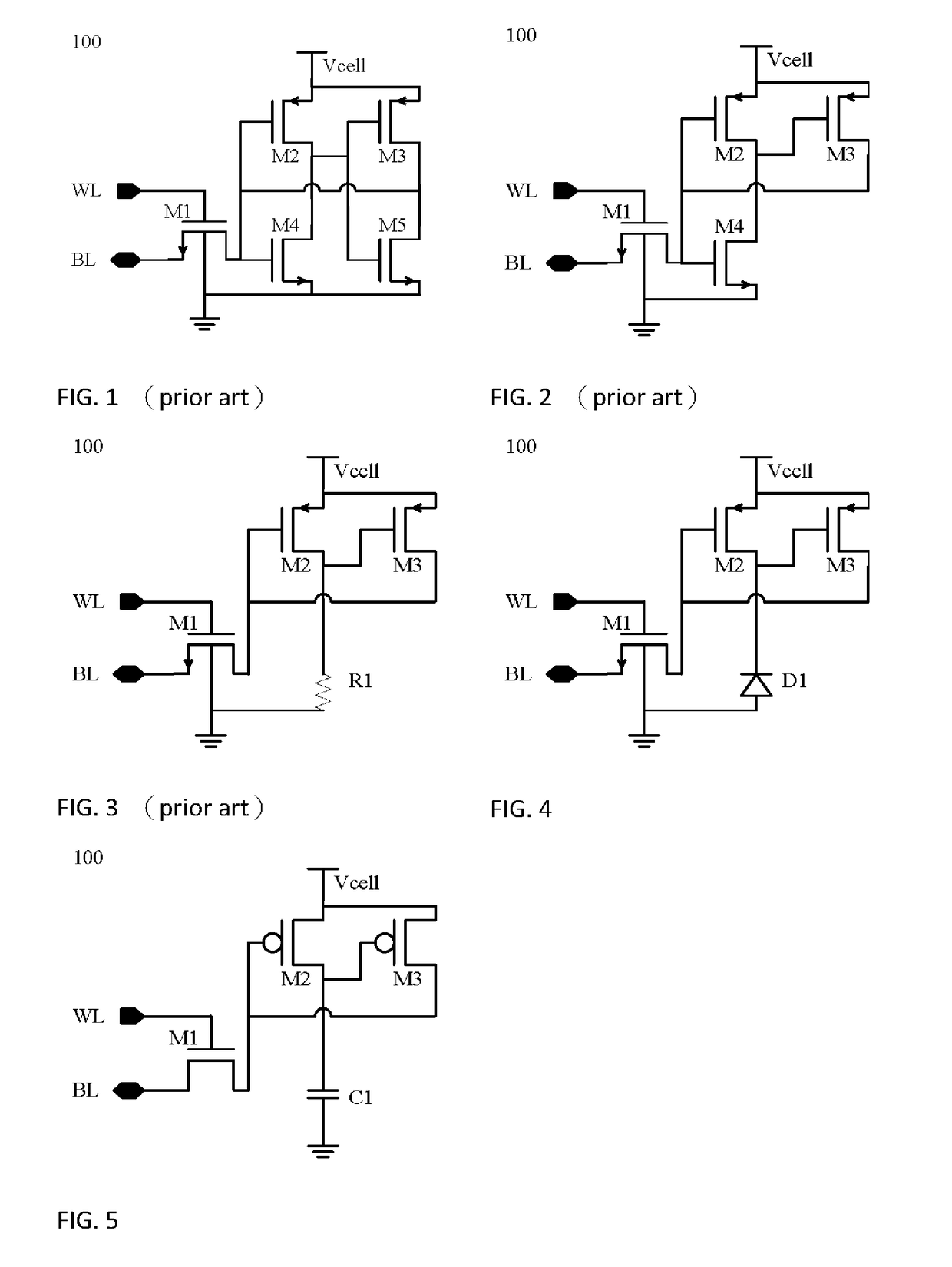

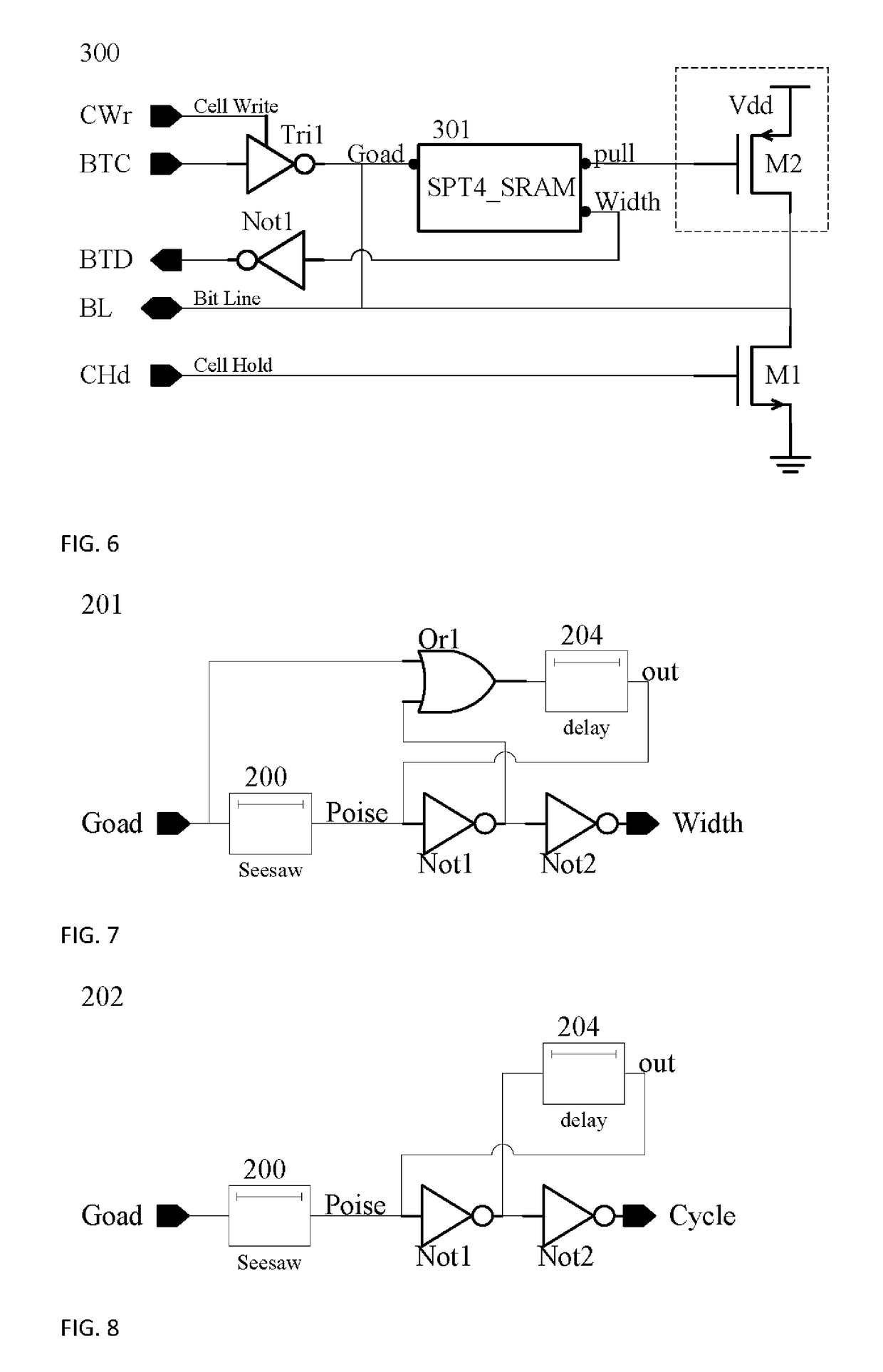

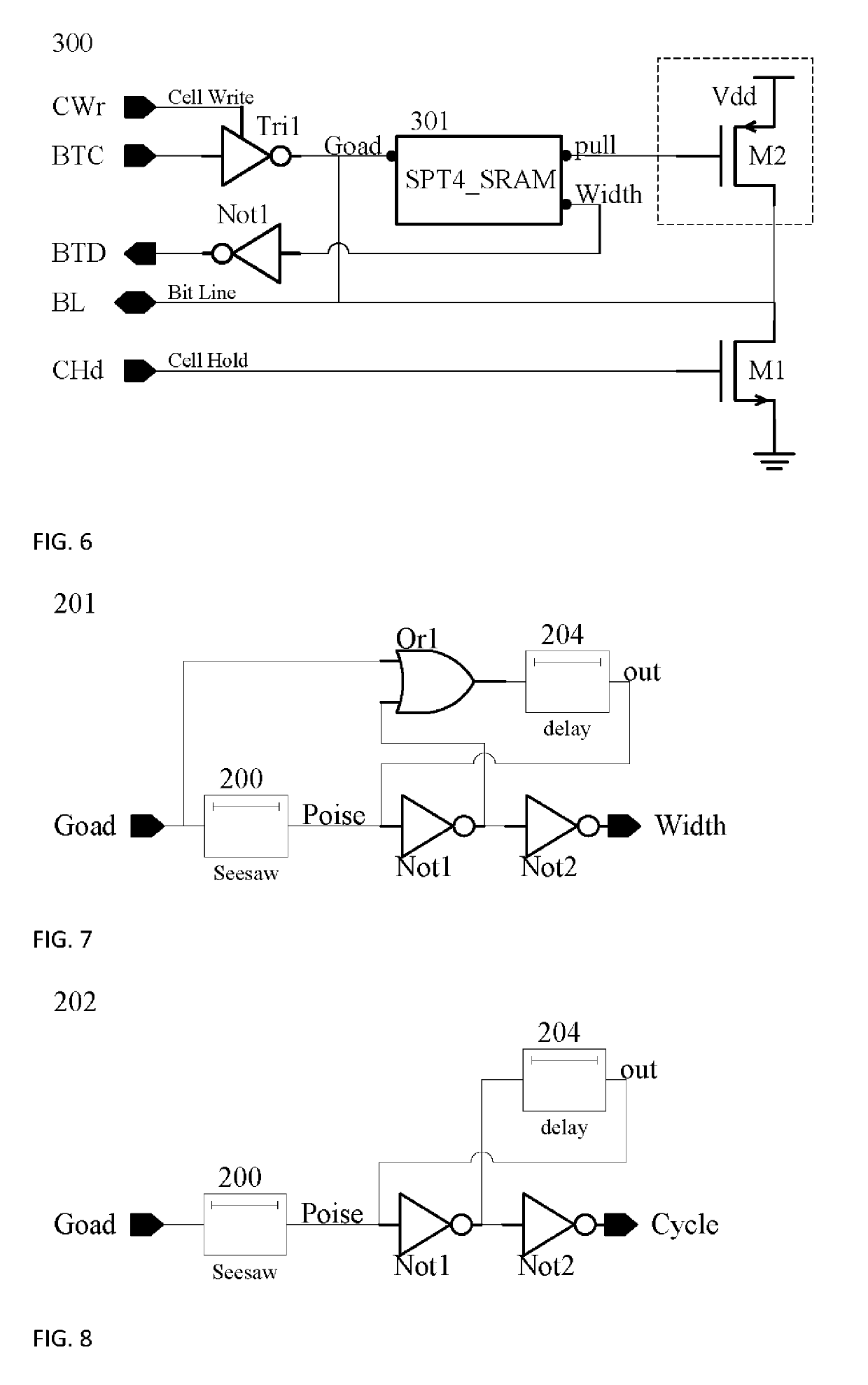

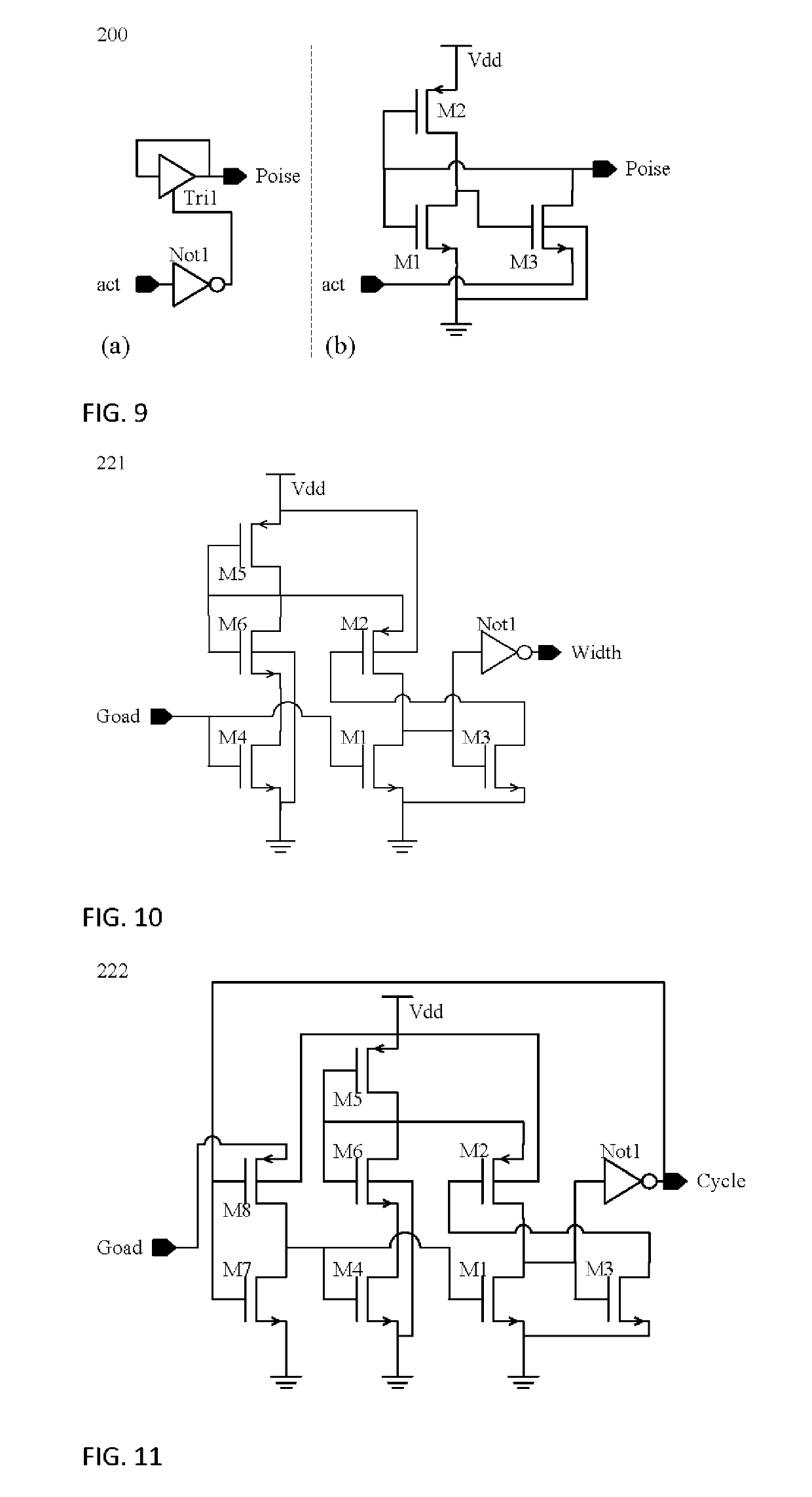

Random-Access Memory and Associated Circuit, Method and System

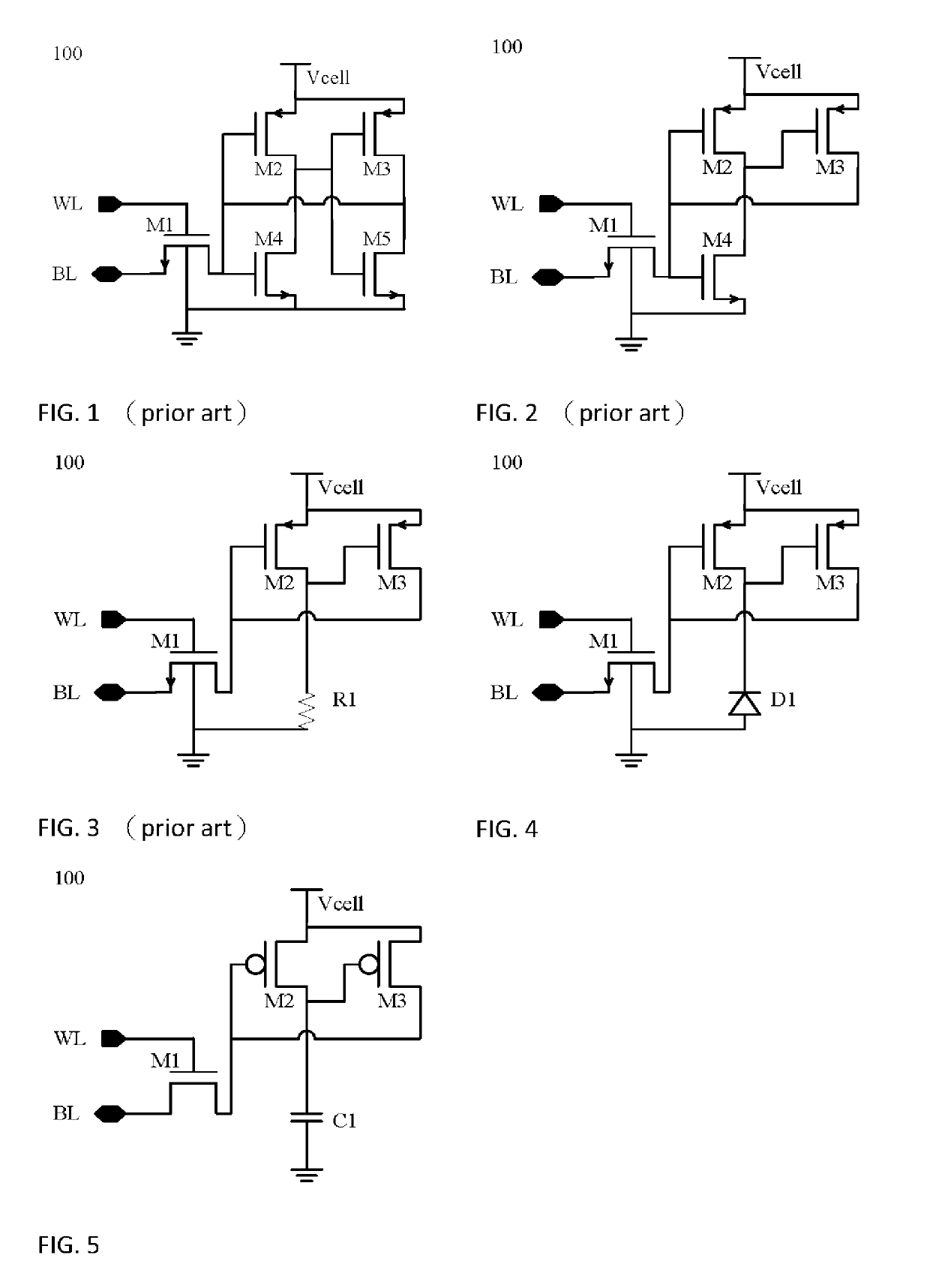

The beginning of using Complementary Metal-Oxide-Semiconductor (CMOS) process technology to implement Static Random-Access Memory (SRAM) which transistor number is six. And then reducing transistor number for increasing integration density, but it will diminish the stability of memory, and also may enhance the complexity of access circuit, thus increasing the power consumption. For increasing the integration density of SRAM, and according to the electrical characteristics of reduced transistor number therefore designing the memory possess low power consumption and its corresponding circuits, and then implementing an access system. If electrical characteristic of the other various memories are similar to SRAM, such as Dynamic Random-Access Memory (DRAM), so they can also use the corresponding access circuit of SRAM.

Owner:TANG CHAO JING

Information processing apparatus

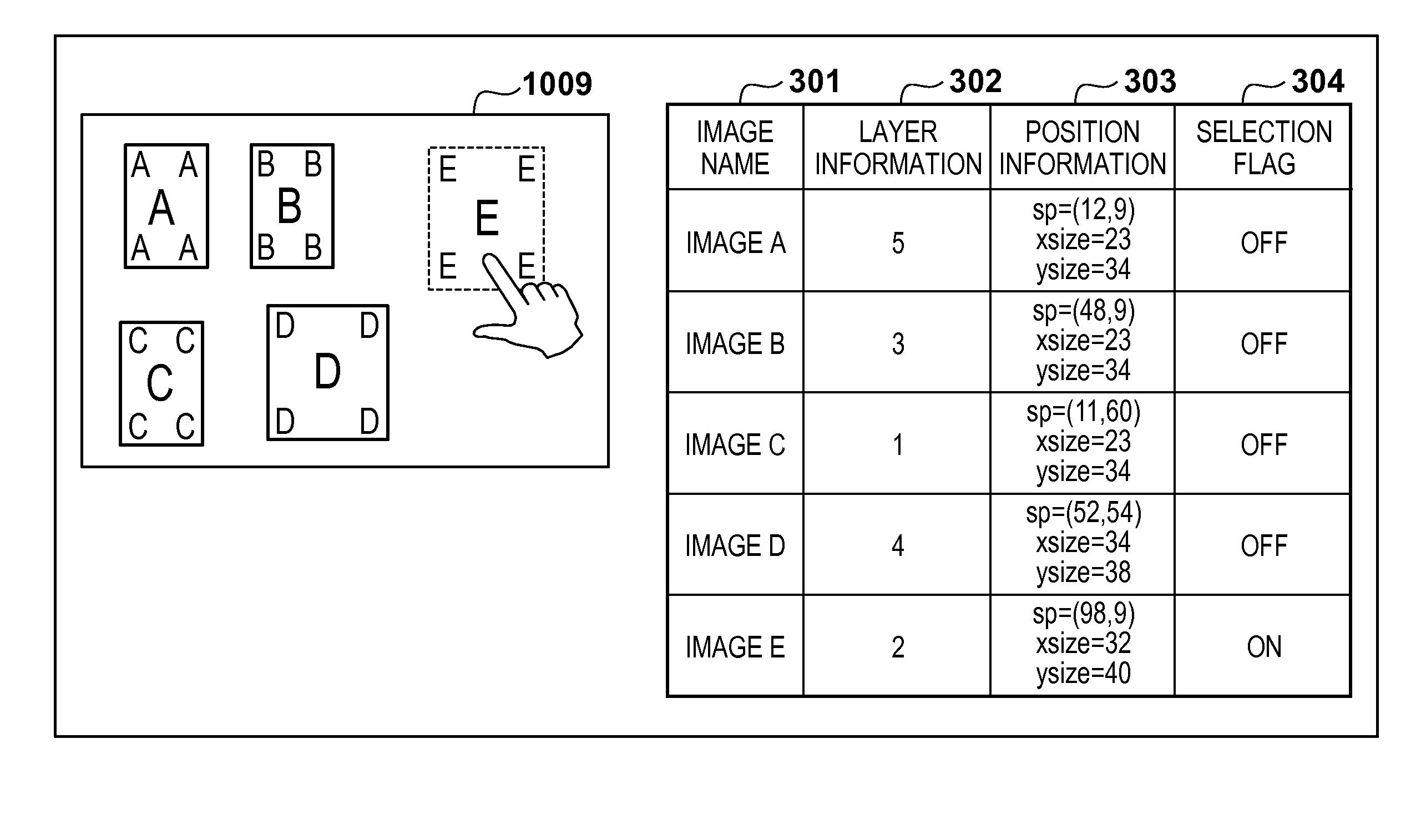

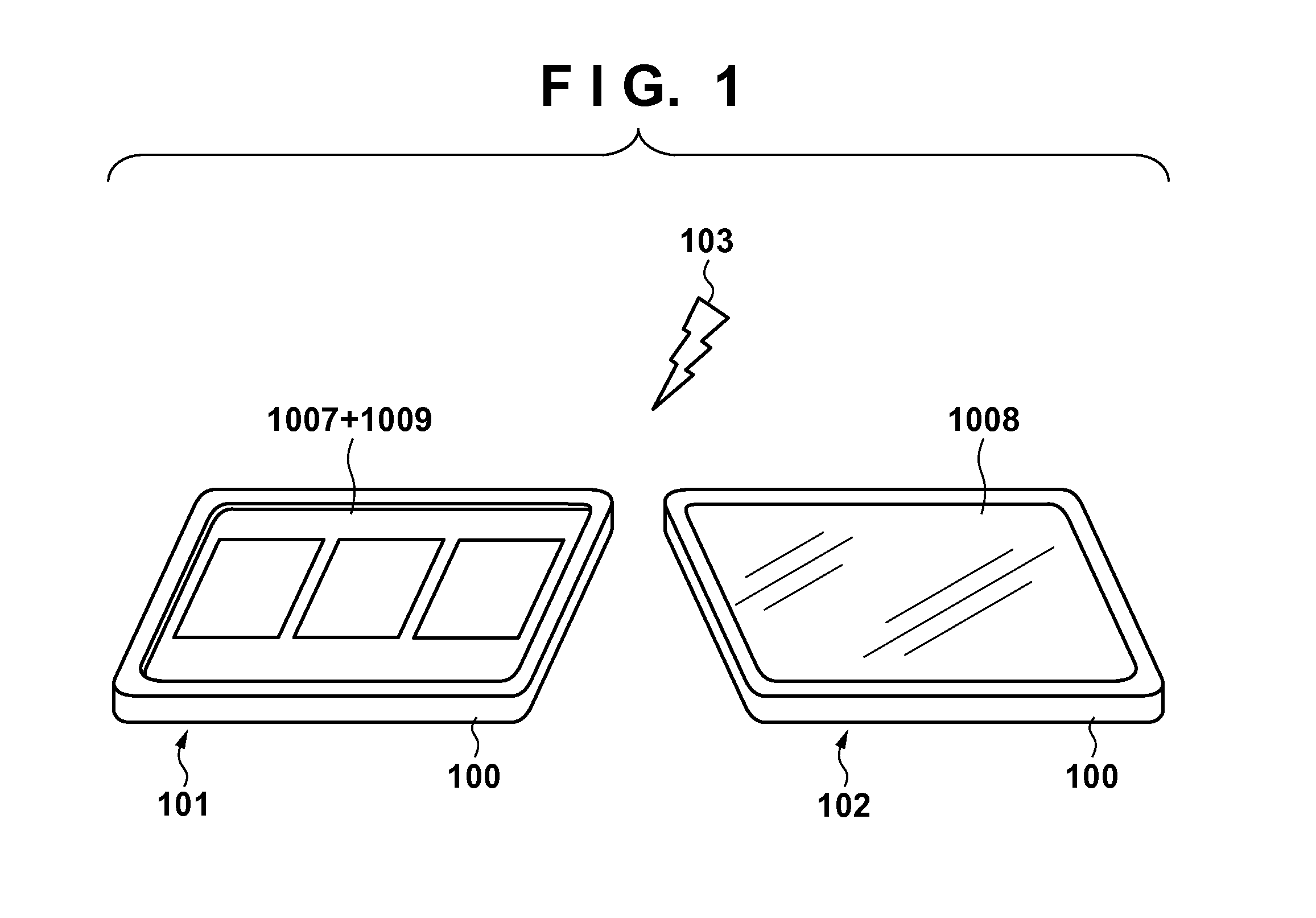

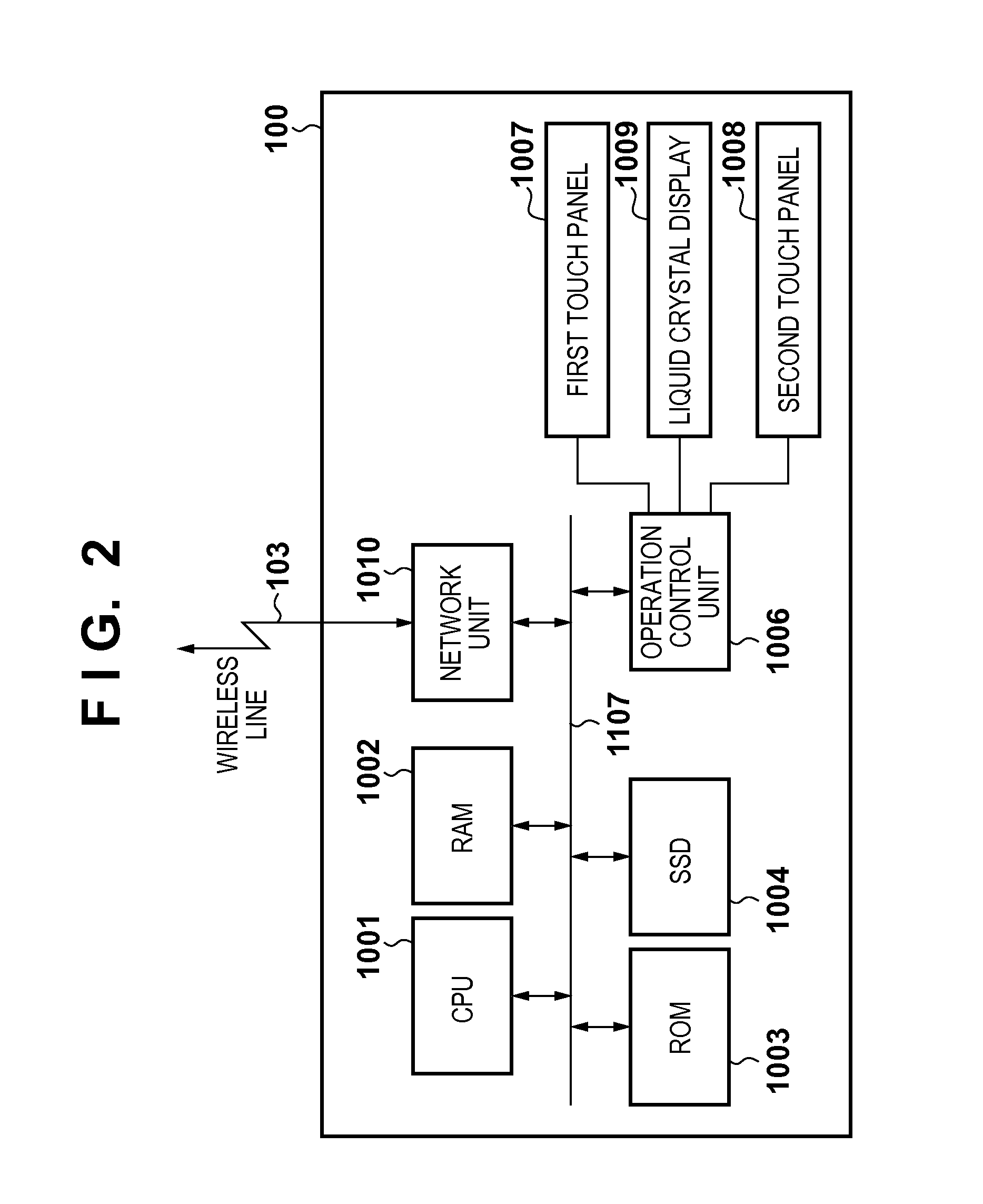

InactiveUS20140165011A1Reduce hierarchyImprove user convenienceInput/output processes for data processingInformation processingComputer graphics (images)

When a plurality of images are laid out within one page, the images may overlap each other. There is provided a layer change unit configured to, if the images overlap each other, intuitively change the hierarchical level of an image to perform processing for an image hidden behind another image, thereby allowing processing for the image hidden behind the other image by changing the hierarchical level of the image while maintaining its position without moving the image.

Owner:CANON KK

1T1D DRAM cell and access method and associated device for DRAM

ActiveUS10482951B2Improve performanceReduce in quantityDigital storageCMOSStatic random-access memory

Owner:TANG CHAO JING

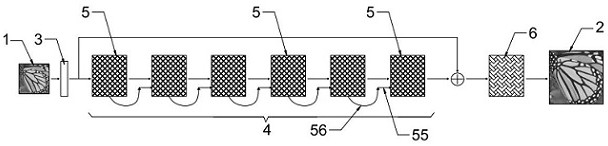

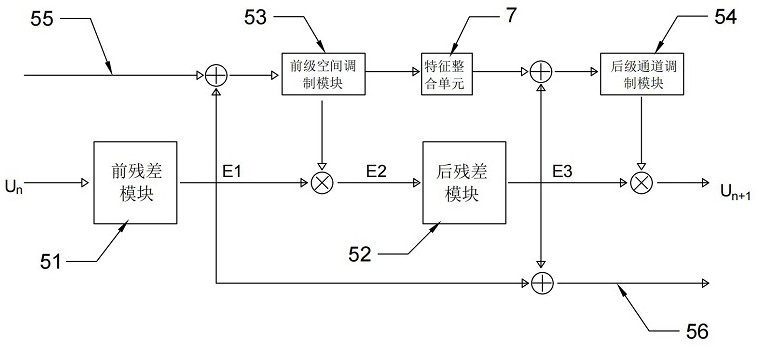

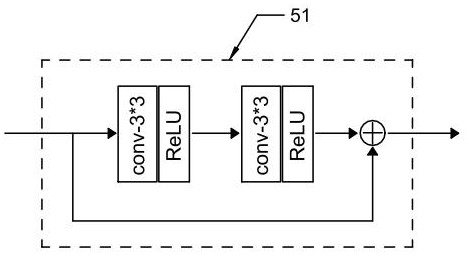

Image super-resolution reconstruction method based on convolutional neural network

ActiveCN114820328AImprove the strengthening effectImprove image qualityGeometric image transformationNeural architecturesImage manipulationReconstruction method

The invention discloses an image super-resolution reconstruction method based on a convolutional neural network, and belongs to the technical field of artificial intelligence and image processing, and the method comprises the steps: obtaining a primary image of which the resolution needs to be improved, obtaining a super-resolution reconstruction convolutional neural network, receiving the primary image as an input through a preliminary convolution layer, and obtaining a secondary image of which the resolution needs to be improved; and inputting the preliminary feature map into a deep feature mapping unit, so that each integrated feature extraction module performs feature extraction operation on the feature map in sequence, and an image reconstruction unit performs super-resolution reconstruction on the comprehensive feature map. Average pooling, maximum pooling and median pooling are set in the two attention mechanisms to perceive important information in an image, and part of modulation information in a front-stage space modulation module is input into a rear-stage channel modulation module by setting a feature integration unit. Therefore, the post-stage channel modulation module has the visual fields in the space direction and the channel direction at the same time, and the network has the advantages of good reconstruction effect, high robustness and the like.

Owner:WEIHAI VOCATIONAL COLLEGE

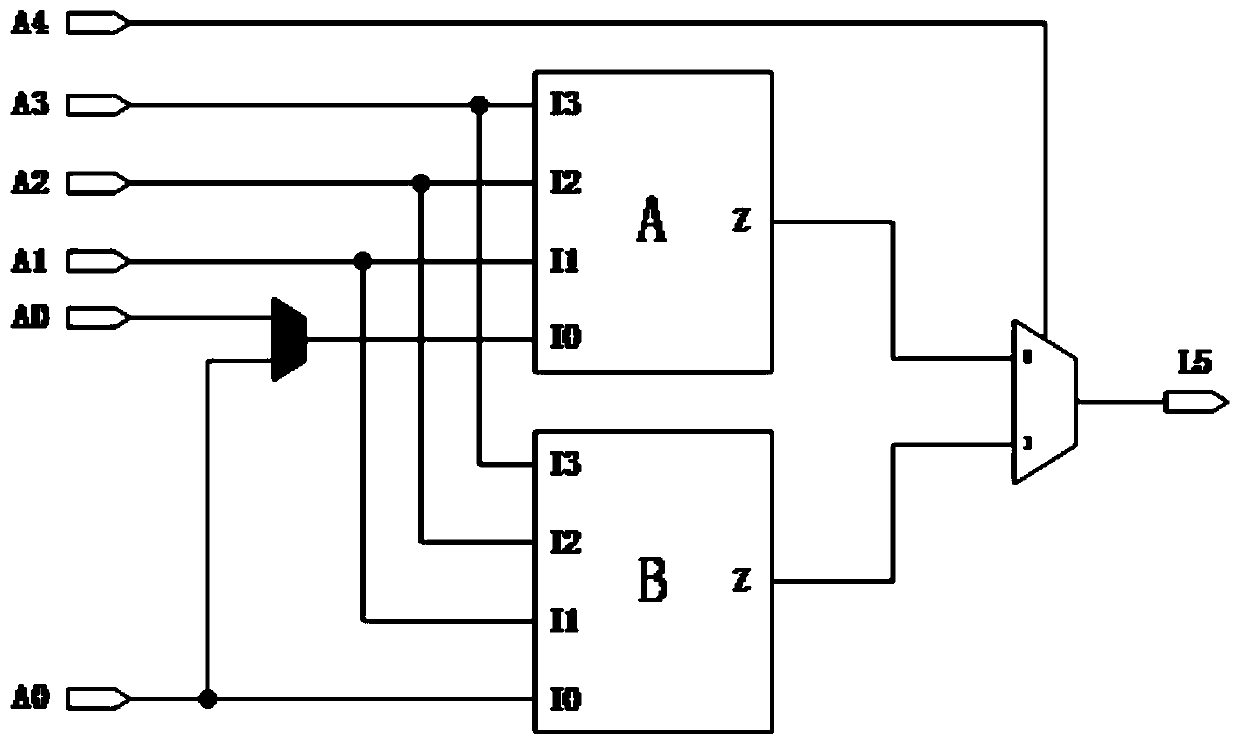

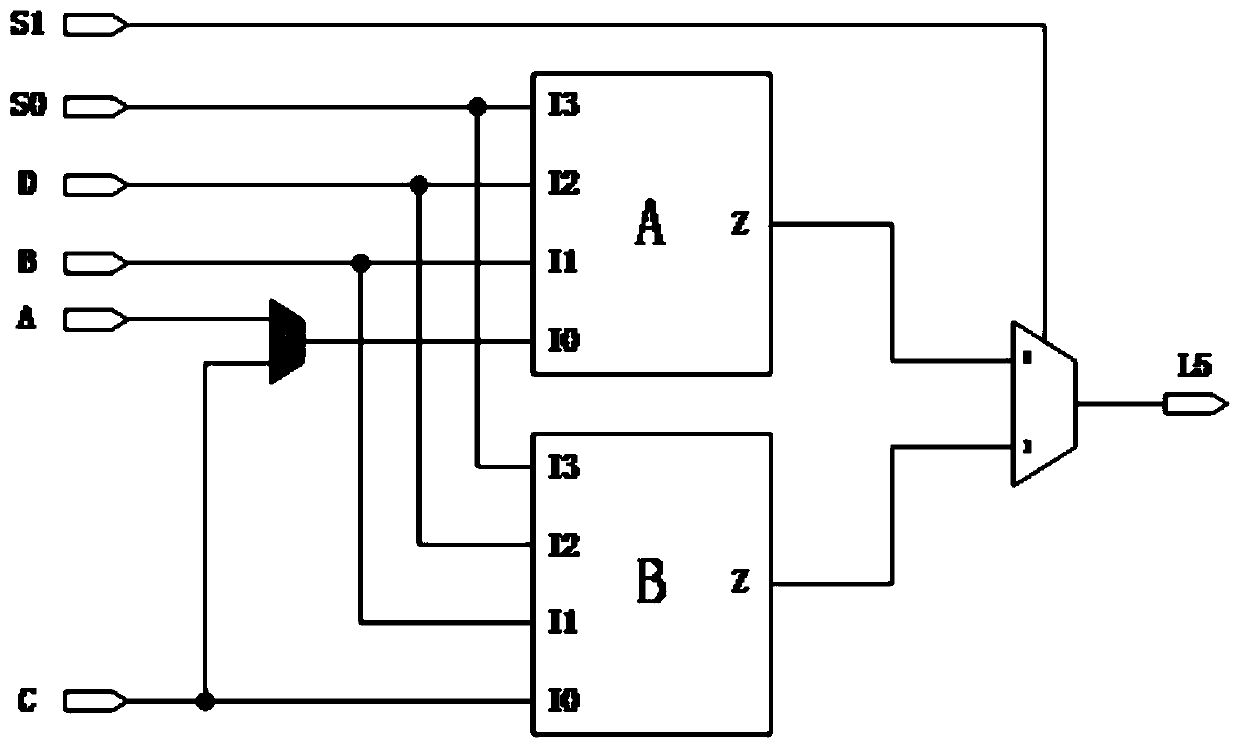

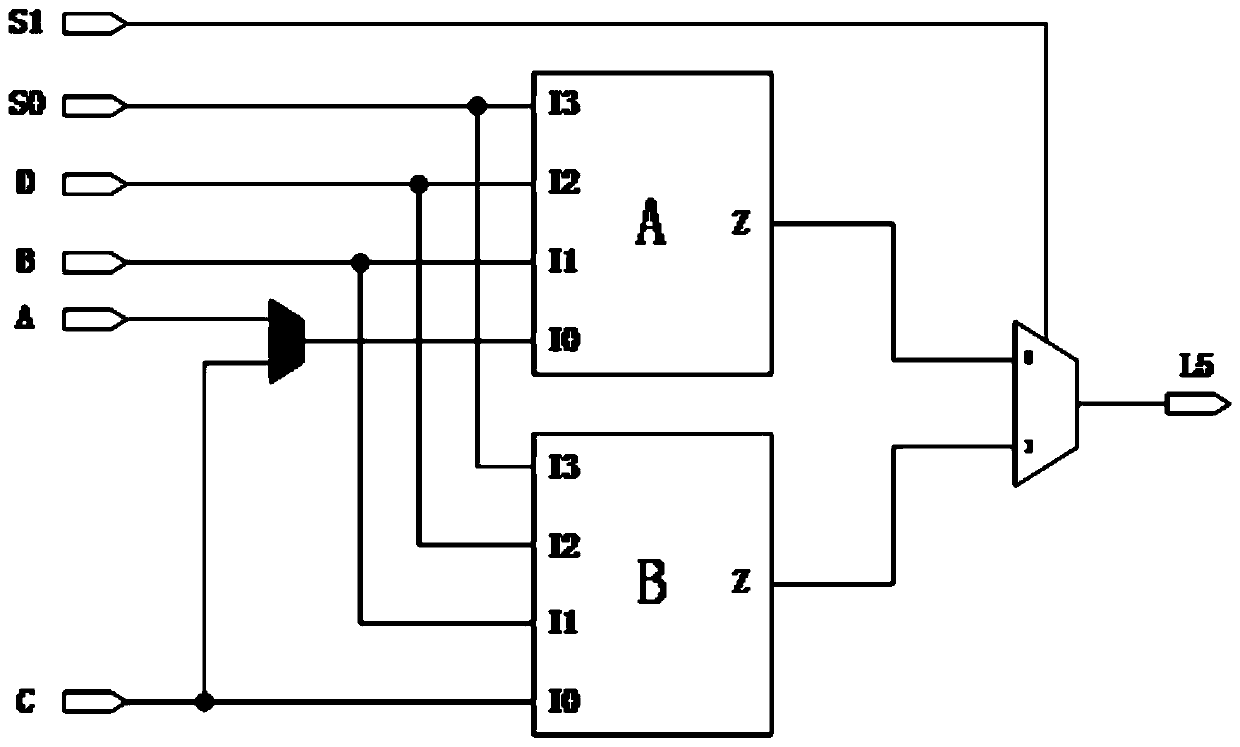

Process mapping method for FPGA with specific structure

ActiveCN110543664AReduce areaImprove performanceSpecial data processing applicationsComputer architectureResource utilization

The invention provides a process mapping method for an FPGA with a specific structure. An input netlist of the process mapping method comprises at least one two-input first node and at least one MUX2node, and includes the steps: respectively obtaining at least one mapping scheme of which the mapping structure corresponding to the first node is a LUT structure, obtaining at least two mapping schemes that the mapping structure corresponding to the MUX2 node is an LUT structure and the mapping structure corresponding to the MUX2 node is mapped to at least one of an LUT5M structure, an MUX2L6 structure, an MUX2L7 structure and an MUX2L8 structure, and determining the optimal mapping scheme corresponding to the first node and the MUX2 node; and obtaining a map-point node in the first node andthe MUX2 node, and generating a corresponding optimal netlist structure one by one according to the optimal mapping scheme of the first node or the MUX2 node where the map-point node is located. The process mapping method achieves the effects of greatly improving the resource utilization rate of the specific LUT5M mode, the specific MUX2L6 structure, the specific MUX2L7 structure and the specificMUX2L8 structure of the FPGA with the specific structure, reducing the circuit area, reducing the hierarchy of the LUT-level netlist and improving the circuit performance.

Owner:SHENZHEN PANGO MICROSYST CO LTD

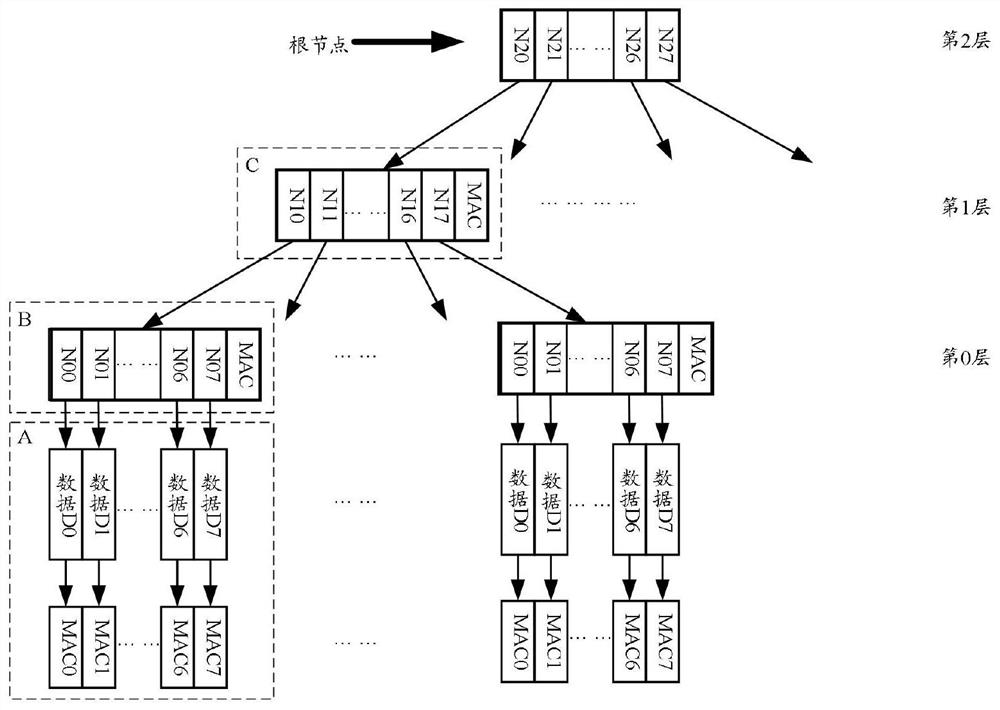

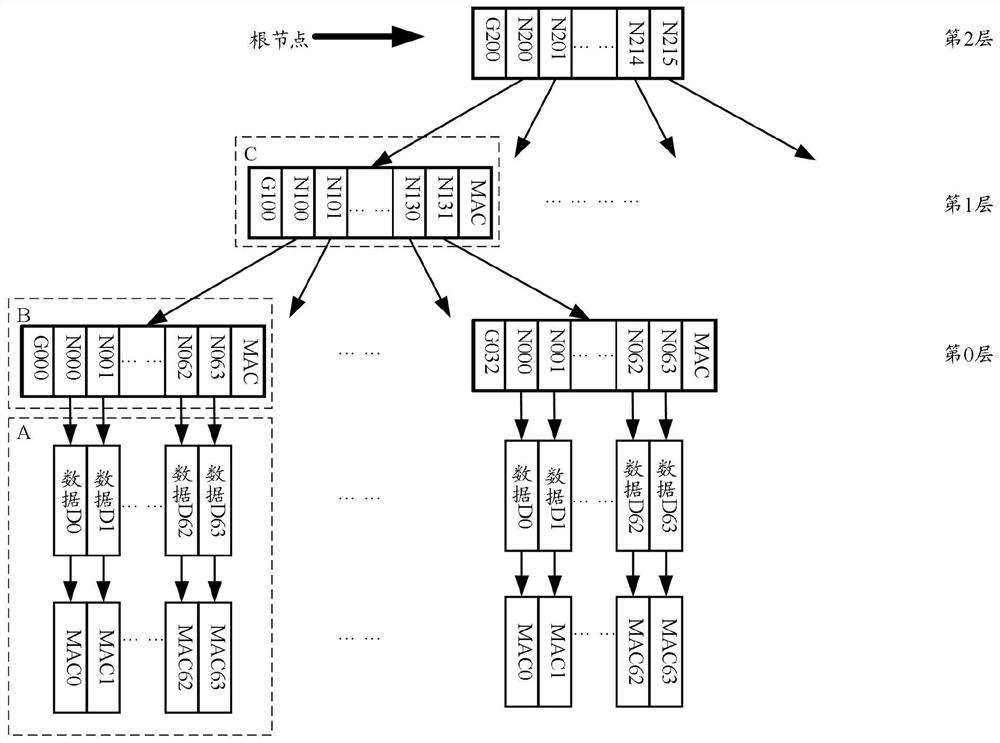

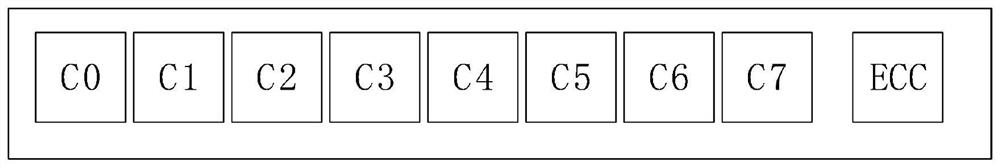

Page table integrity protection method, device and equipment

ActiveCN112597488ASmall amount of calculationHigh repetition ratePlatform integrity maintainanceMemory systemsPage tableGoal node

Embodiments of the invention provide a page table integrity protection method, device and equipment. The method comprises the steps of determining a to-be-verified target data item in a page table; starting from the next node layer of the root node of a protection tree, verifying the target node associated with the target data item in each node layer of the protection tree in sequence until the target node directly associated with the target data item in the tail end node layer of the protection tree is verified; and determining the integrity of the target data item based on the verification result of the target node. The MAC of the node of the protection tree for page table integrity protection is calculated based on the data in the node, a local counter directly associated with the nodeand a global counter corresponding to the local counter, so that the protection tree constructed based on the data can have fewer hierarchies, and the calculation amount of page table integrity protection can be reduced.

Owner:HYGON INFORMATION TECH CO LTD

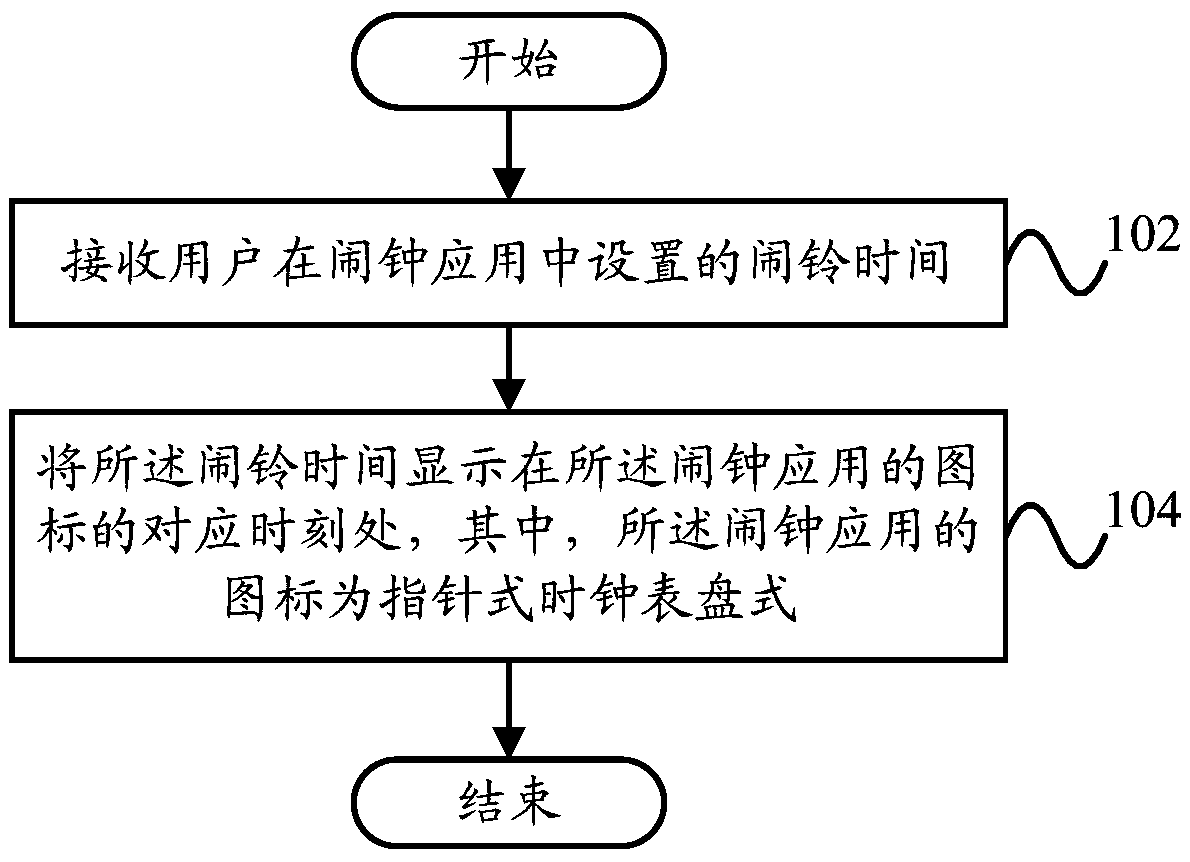

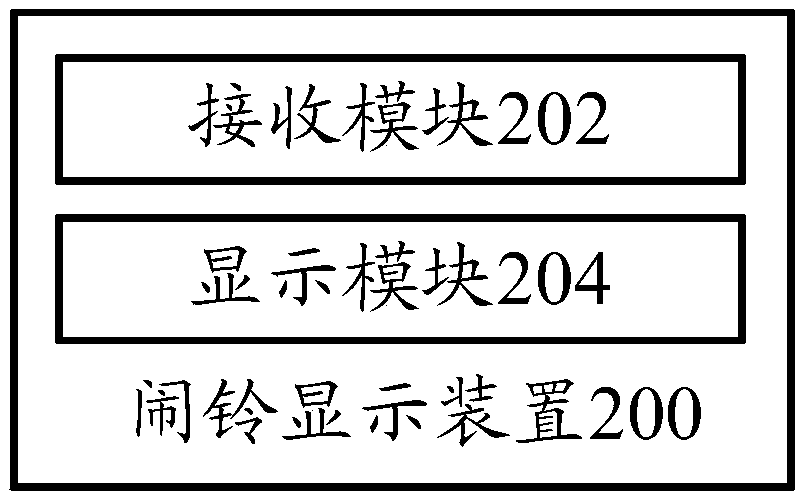

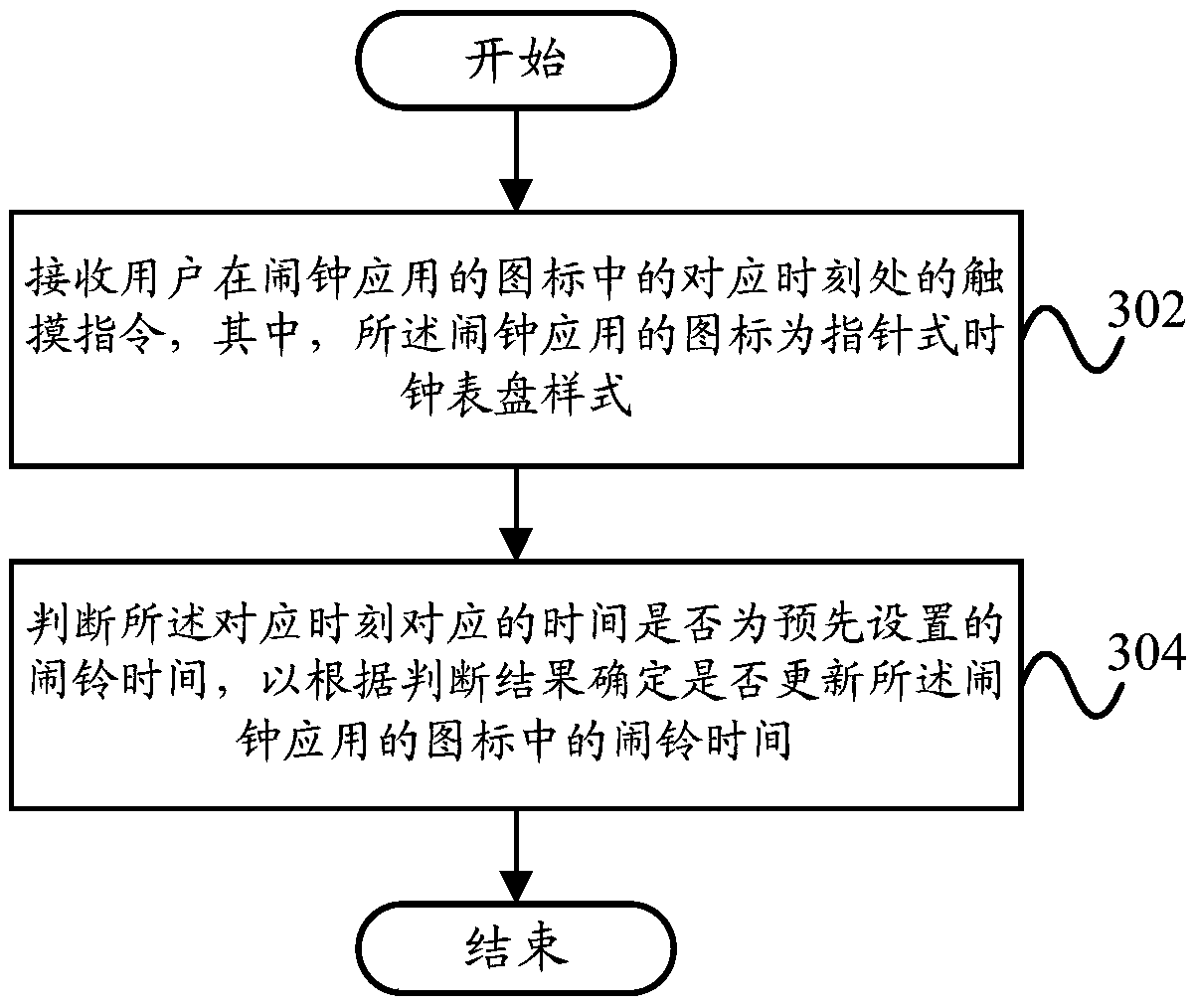

Alarm display method and alarm display device

InactiveCN105516491AImprove practicalityReduce hierarchySubstation equipmentDisplay deviceComputer science

The invention discloses an alarm display method and an alarm display device. The alarm display method comprises: receiving alarm time set in an alarm application by a user; and displaying the alarm time at a moment corresponding to an icon of the alarm application, wherein the icon of the alarm application is of an analog clock dial shape. By the technical scheme of the invention, direct regulation and display of the alarm time on the icon of the alarm application can be achieved, so that hierarchies of alarm display and alarm setting are reduced, and not only intelligence and convenience of alarm display and alarm setting are improved, but also practicality of the icon of the alarm application is reinforced, thereby promoting user experience.

Owner:MEIZU TECH CO LTD

Multifunctional protective clothing fabric

InactiveCN107571579AImprove adhesionGood acid and alkali resistanceChemical protectionHeat protectionEmulsionPlain weave

The invention discloses a multifunctional protective clothing fabric. The fabric comprises a surface layer, a heat-insulating layer and a lining layer which are in successive bonding, wherein the surface layer comprises a polyphenylene sulfide fabric and a polytetrafluoroethylene film, and is prepared through the following steps: subjecting the polyphenylene sulfide fabric to modifying treatment with a mixed solution of a polytetrafluoroethylene emulsion, polyhexafluoropropylene, a silane coupling agent, active polypeptide, a film-forming agent and water, and subjecting the polytetrafluoroethylene film and the modified polyphenylene sulfide fabric to hot-pressing compounding; the heat-insulating layer is a spunlace non-woven fabric which is prepared from aramid fiber, polysulfonamide fiberand polytetrafluoroethylene fiber; and the lining layer is a blended plain weave fabric of aramid fiber and flame-retardant polyester fiber. The invention has the following beneficial effects: the protective clothing fabric provided by the invention has the advantages of high softness, light weight, comfortability in wearing, easy processing and seaming, excellent acid and alkali resistance, flame retardance, heat insulation, capability of better resisting flame and toxic gas, and excellent water resistance.

Owner:海盐派特普科技有限公司

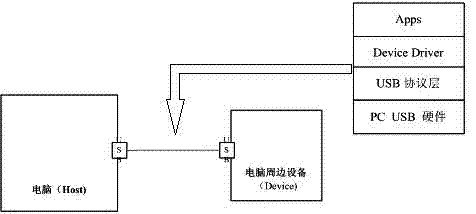

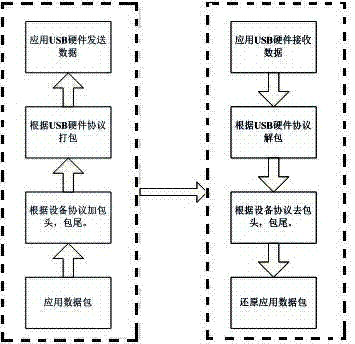

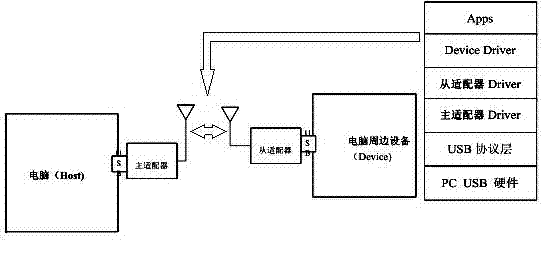

Method for simply and wirelessly matching computer and temote USB (universal serial bus) peripheral

InactiveCN103699510AReduce hierarchySave software and hardware resourcesElectric digital data processingData transmissionPeripheral

The invention discloses a method for simply and wirelessly matching a computer and a remote USB (universal serial bus) peripheral. The method comprises the following steps of (1) establishing a wireless protocol simple bridging physical structure: respectively connecting a pair of wireless transmitter and wireless receiver onto a computer USB port and a USB port of a remote USB peripheral; (2) realizing the data transmission and receiving between the computer and the computer remote USB peripheral on the basis of a transmission protocol stack comprising a computer application layer, a device drive layer, a USB protocol layer and the remote USB peripheral. In the method, the wireless receiver-transmitter is only used as a relay, so that the peripheral is equivalent to the wireless peripheral device of the computer; all USB signaling and data are carried by the wireless protocol, the data relay is transparent through the matching conversion of a USB logic passage and a wireless logic passage, and all signaling and data can be nondestructively and directly transmitted through the wireless protocol. By adopting the method, few protocol stack layers are needed, the communication protocol is simplified, and the high-speed wireless transmission between the computer and the remote USB peripheral can be realized.

Owner:林剑颖

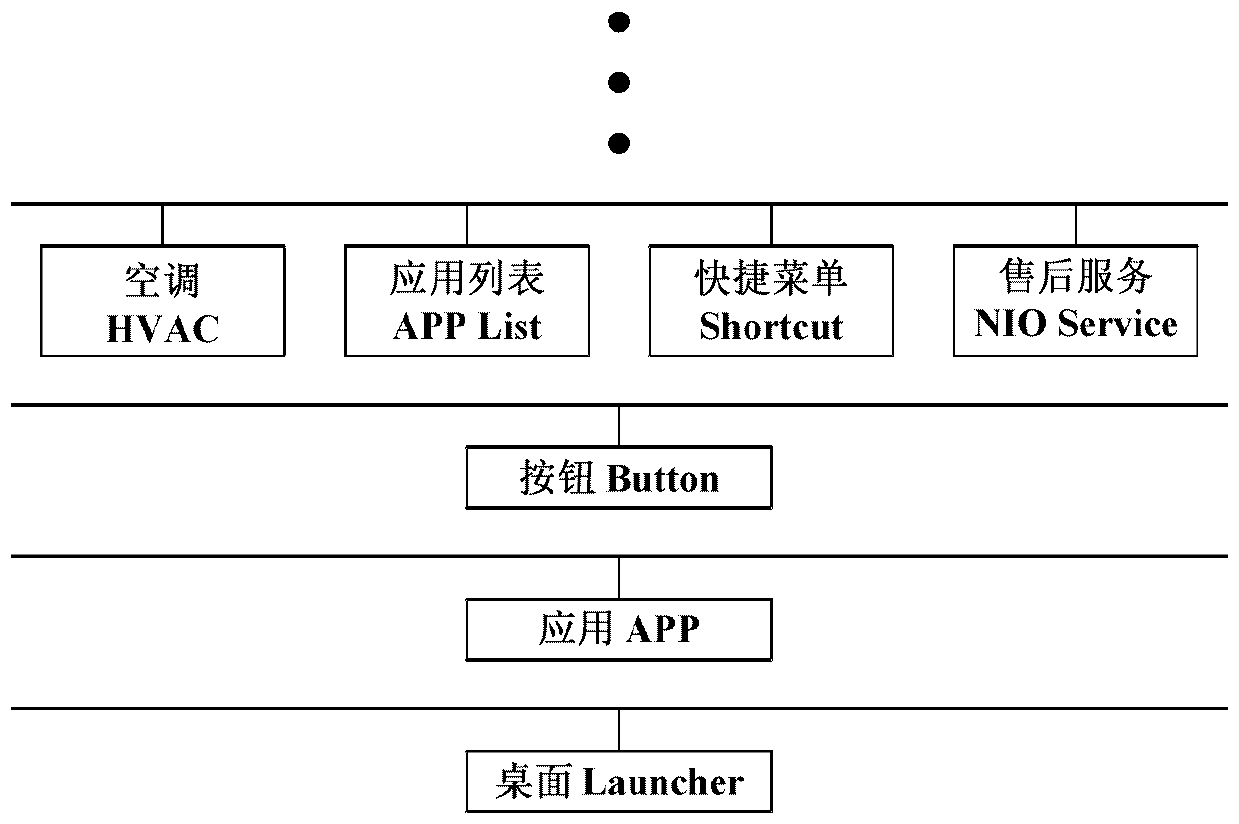

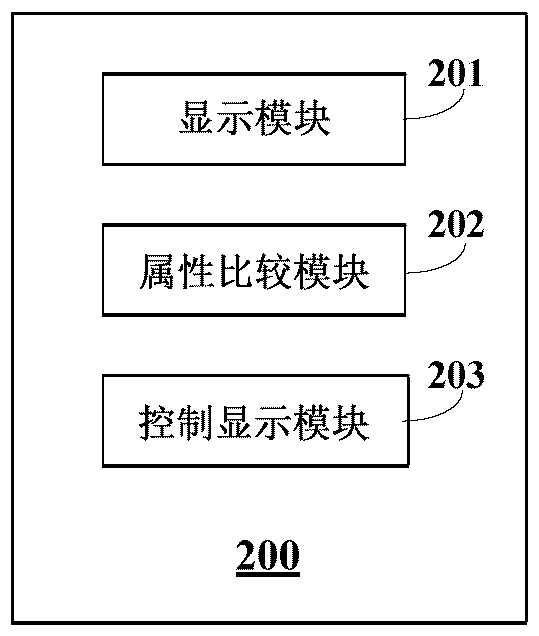

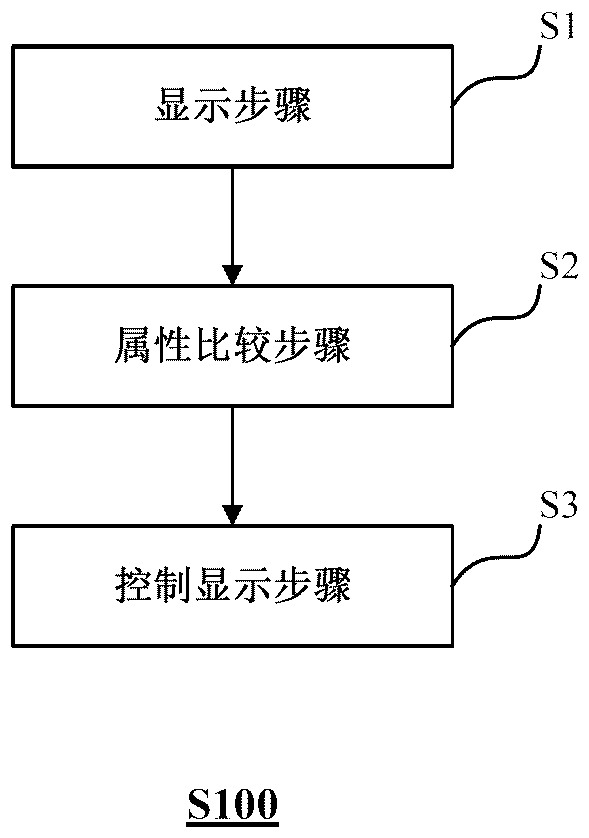

Vehicle-mounted terminal equipment, display control method and device, computer equipment and recording medium

ActiveCN109933391AInteractions are short and shallowReturn quicklyVehicle componentsExecution for user interfacesTerminal equipmentComputer terminal

The invention relates to a vehicle-mounted terminal device, a display control method, a display control device, a computer device and a recording medium. The vehicle-mounted terminal device comprisesa display used for providing various display interfaces; And a controller, which is used for comparing a predetermined hierarchical attribute of the current display interface with a hierarchical attribute of one display interface to be newly added in response to an instruction of newly adding one display interface from the plurality of display interfaces for displaying; and executing a corresponding operation on the current display interface and the display interface to be newly added based on the comparison result.

Owner:NIO ANHUI HLDG CO LTD

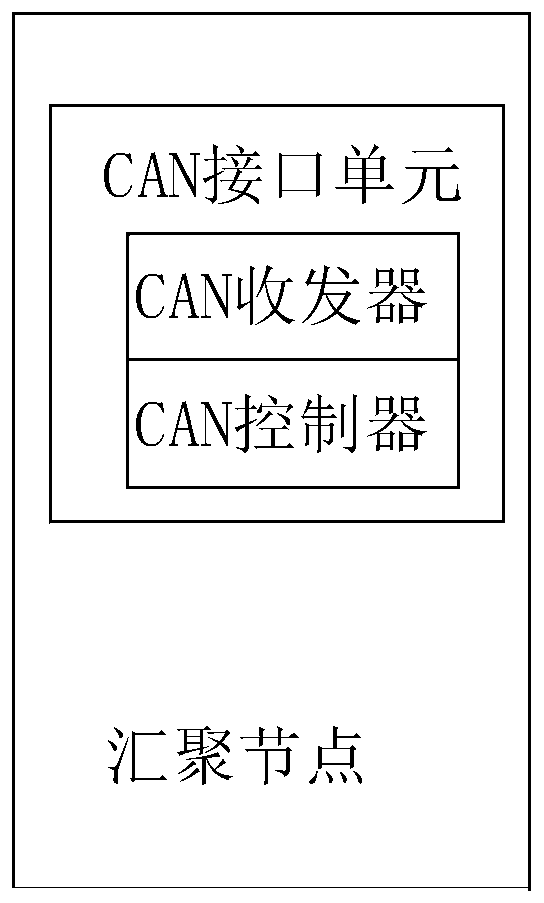

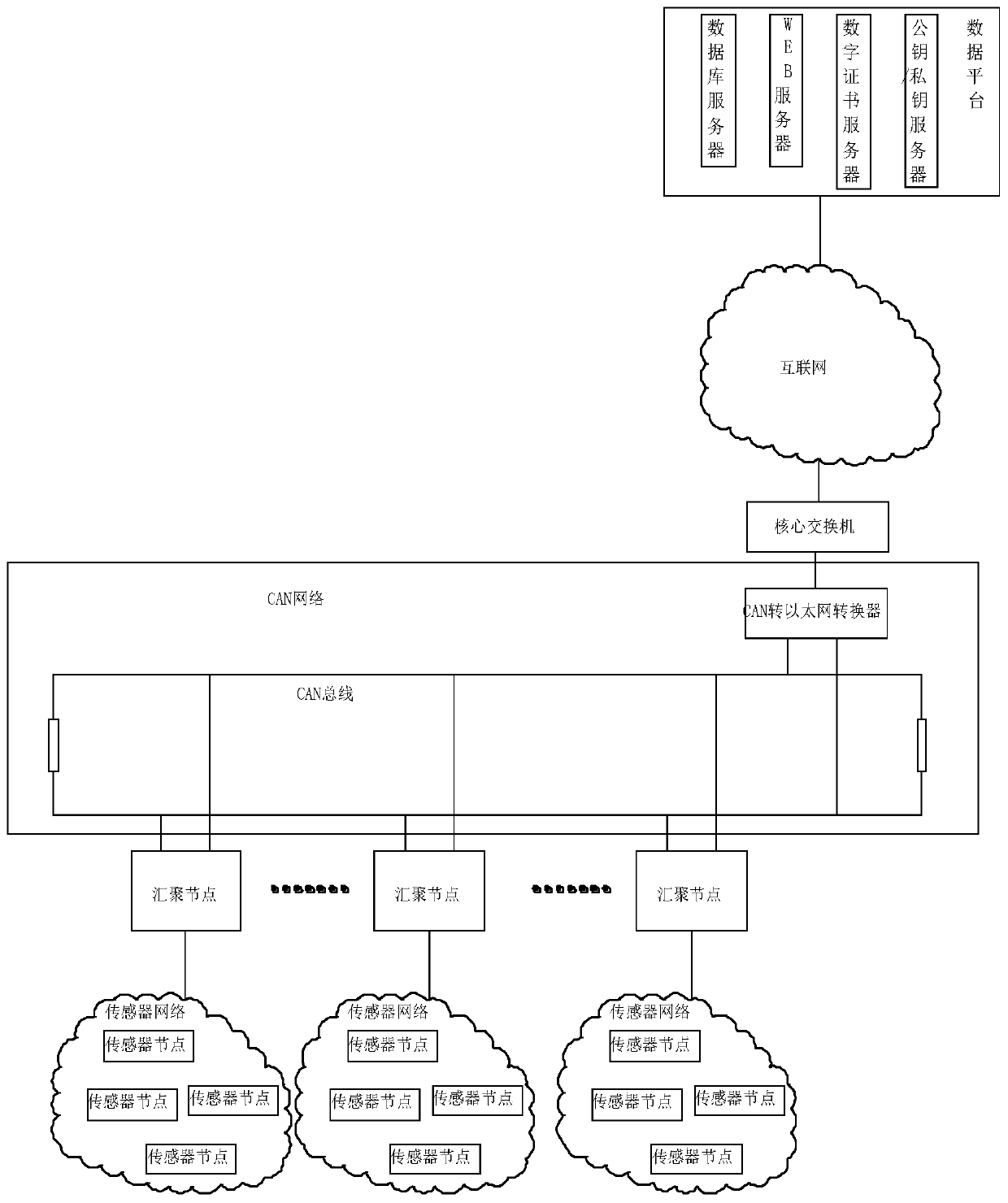

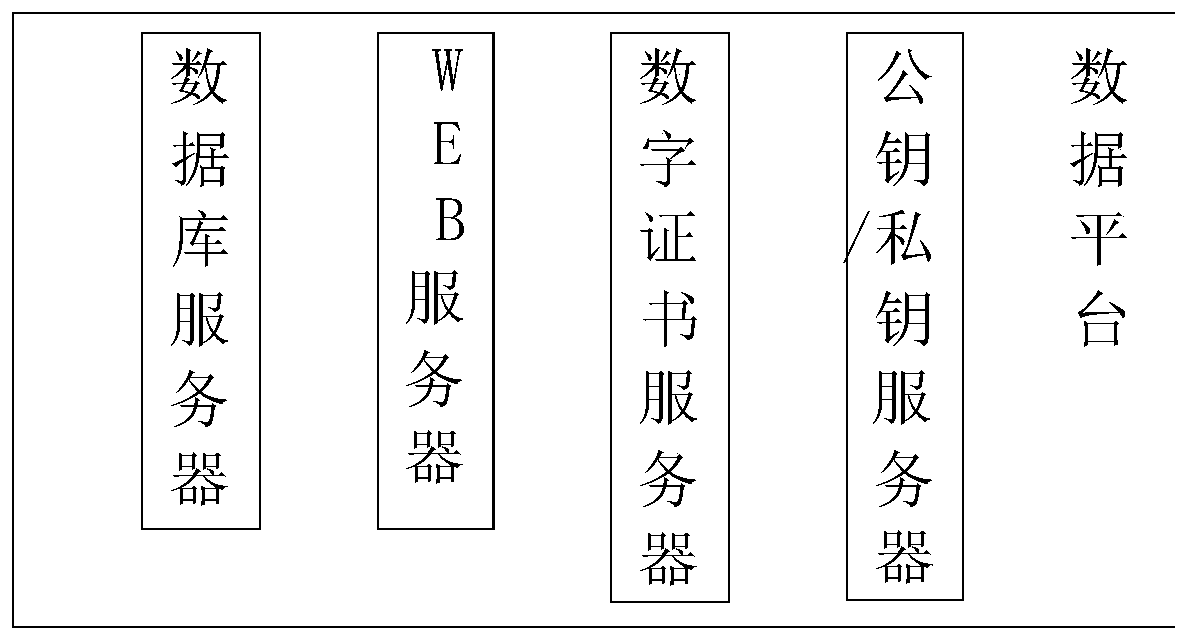

Environmental process warehouse communication system

InactiveCN110769391AReduction of launch range requirementsReduce energy consumptionPower managementParticular environment based servicesData platformThe Internet

The invention discloses an environmental process warehouse communication system. The environmental process warehouse communication system comprises an environmental process warehouse network system, the environmental technology network warehouse system comprises a sensor network and a CAN network. The sensor network comprises a plurality of sensor nodes which are wirelessly interconnected; the CANnetwork includes a CAN bus, the plurality of sensor networks are respectively connected to the aggregation node in a multi-hop manner. The aggregation node is connected to a CAN bus of a CAN networkthrough the CAN interface unit. A plurality of sensor networks and a CAN network form a combined network through aggregation nodes, and the CAN network of a CAN bus is connected with a core switch through a CAN-to-Ethernet converter, is connected to the Internet through the core switch, and is interconnected with a data platform through the Internet; through common networking of the separated sensor network and the on-site CAN network, the network architecture is optimized, the requirement for the coverage range of the wireless sensor nodes is reduced, the node energy consumption is reduced, and the method is worthy of vigorous popularization.

Owner:云南昊协科技有限公司

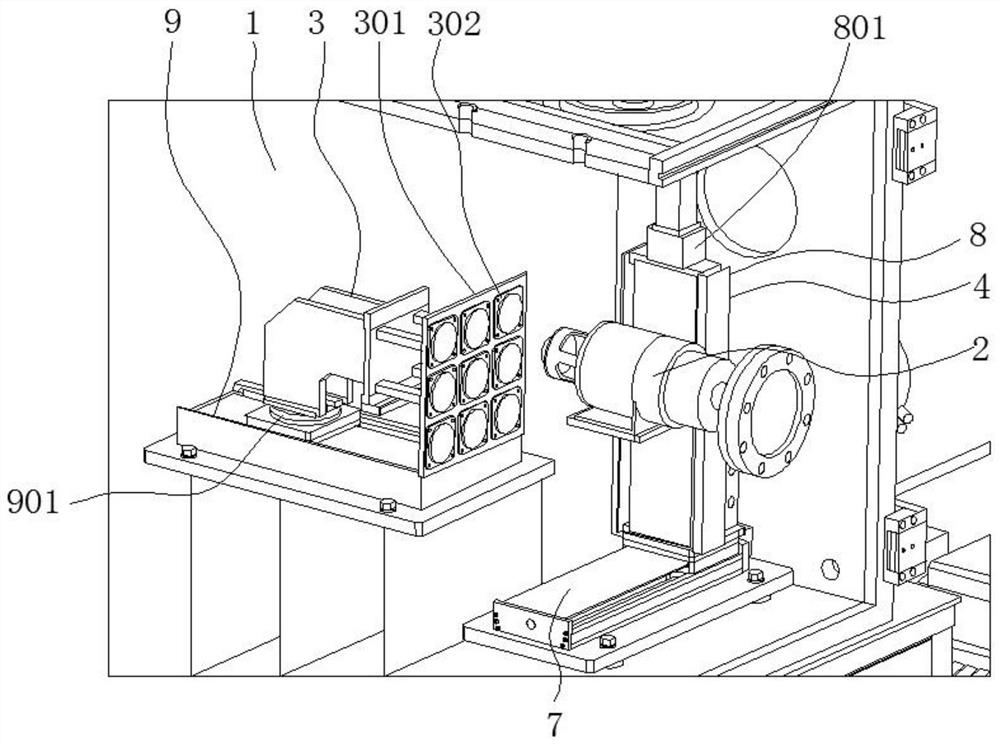

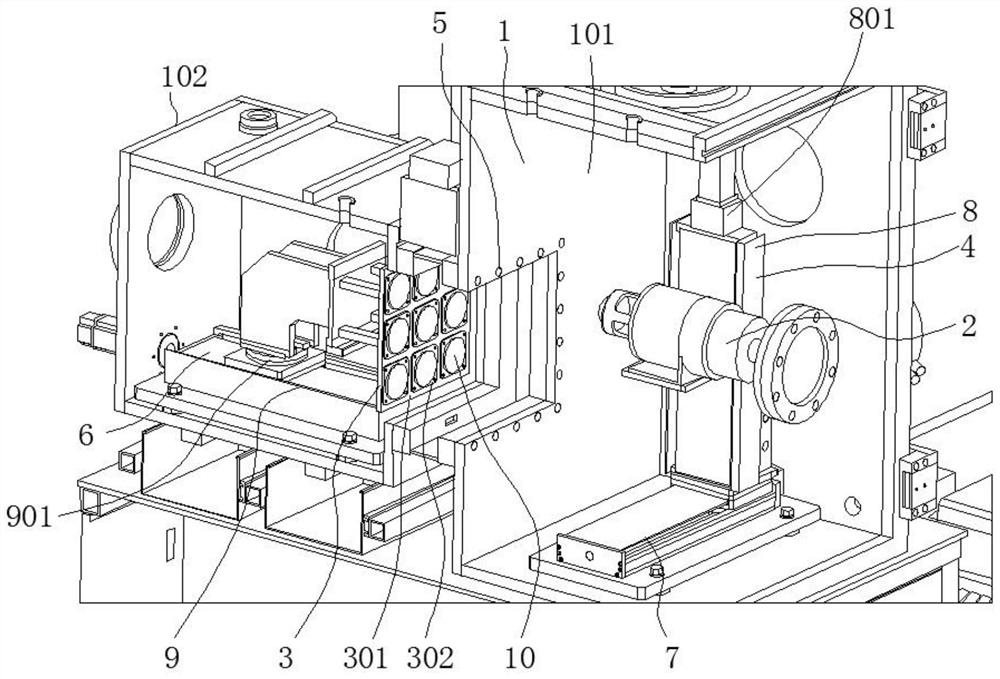

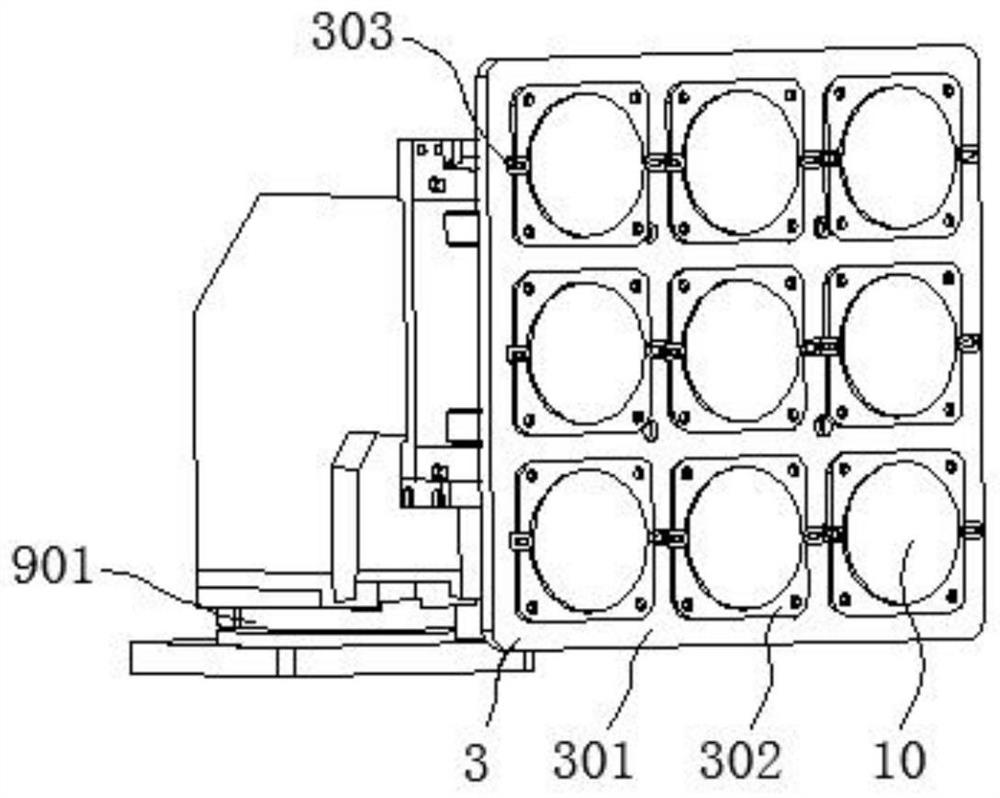

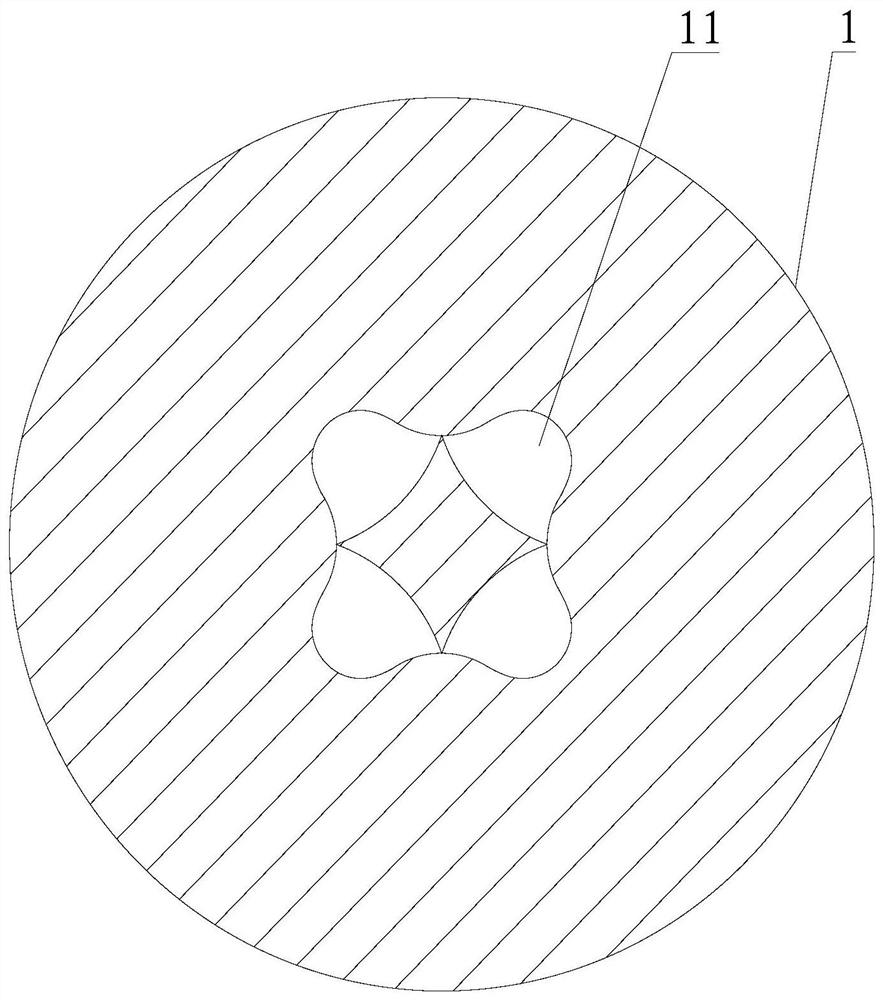

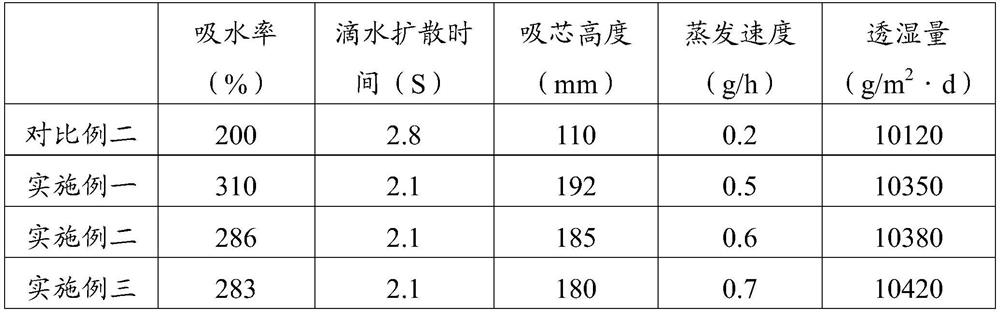

A multi-workpiece ion beam polishing system and method

The invention discloses a multiple-workpiece ion beam polishing system and method. The multiple-workpiece ion beam polishing system comprises a vacuum chamber. A required ion source, a clamp and a movement mechanism are arranged in the vacuum chamber. The ion source generates an ion beam, the clamp is used for clamping workpieces, and the movement mechanism is used for conducting machining control. The multiple workpieces are clamped on the clamp at the same time. According to the multiple-workpiece ion beam polishing system and method, the multiple-workpiece clamp is adopted, the multiple workpieces are clamped at one time, and therefore the time, required by vacuum pumping and debugging of a single workpiece, of a machine is omitted, machining of the multiple surfaces can be conducted onthe multiple workpieces at the same time, the machining time and the machining cost are greatly saved, and the machining efficiency is greatly improved. According to the multiple-workpiece ion beam polishing method, the multiple-station clamp is arranged in the polishing system, the multiple workpieces can be simultaneously clamped to be machined at the same time, and therefore the production efficiency of the machine is further improved. In addition, the distances between the multiple workpieces are judged, an appropriate machining method is adopted, and therefore the purpose of polishing the workpieces on the same clamp at the same time can be achieved.

Owner:长沙埃福思科技有限公司

Manufacturing method of quick-dry polyester fabric

PendingCN113638110AImproves UV protectionImprove comfortWeft knittingWarp knittingYarnPolymer science

The invention discloses a manufacturing method of a quick-dry polyester fabric. The manufacturing method comprises the following steps of (1) mixing organic dibasic acid and dihydric alcohol, and then carrying out a condensation polymerization reaction; (2) adding nano-zinc oxide, titanium dioxide and 2-hydroxy-4-n-octyloxybenzophenone into a product obtained after condensation polymerization, performing mixing, and then carrying out the polymerization reaction again, so as to obtain a copolyester melt; (3) enabling the copolyester melt to be subjected to yarn separation, and then spinning profiled polyester yarns with the fineness of 0.8 dtex to 1 dtex through a profiled spinneret plate; and (4) weaving the prepared profiled polyester yarns and cotton fiber yarns to prepare the polyester fabric. The profiled spinneret plate in the step (3) comprises four spinneret orifices which are arranged in a central symmetry manner and are not communicated with one another, and the four spinneret orifices form a four-leaf shape. The moisture absorption performance and the moisture removal performance of the polyester fabric can be improved, so that the polyester fabric has the quick-drying performance.

Owner:福州市晟浩纺织科技有限公司

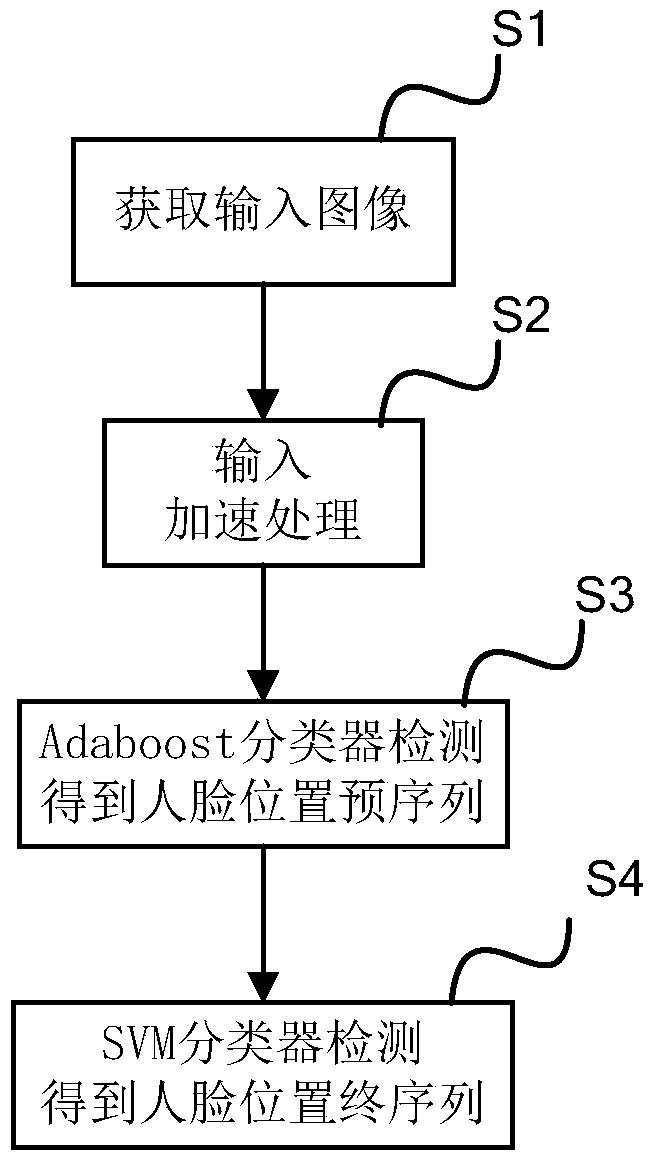

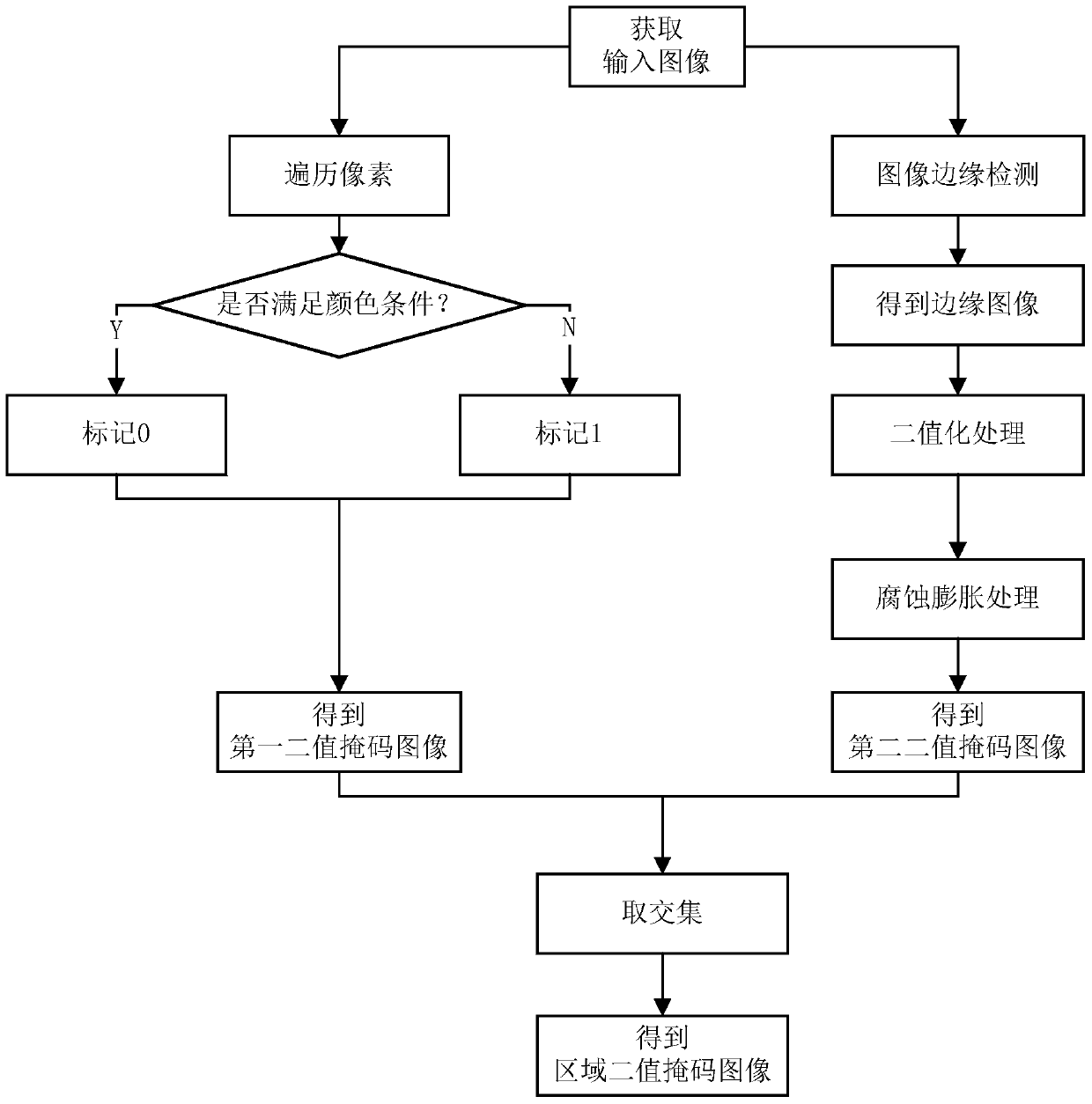

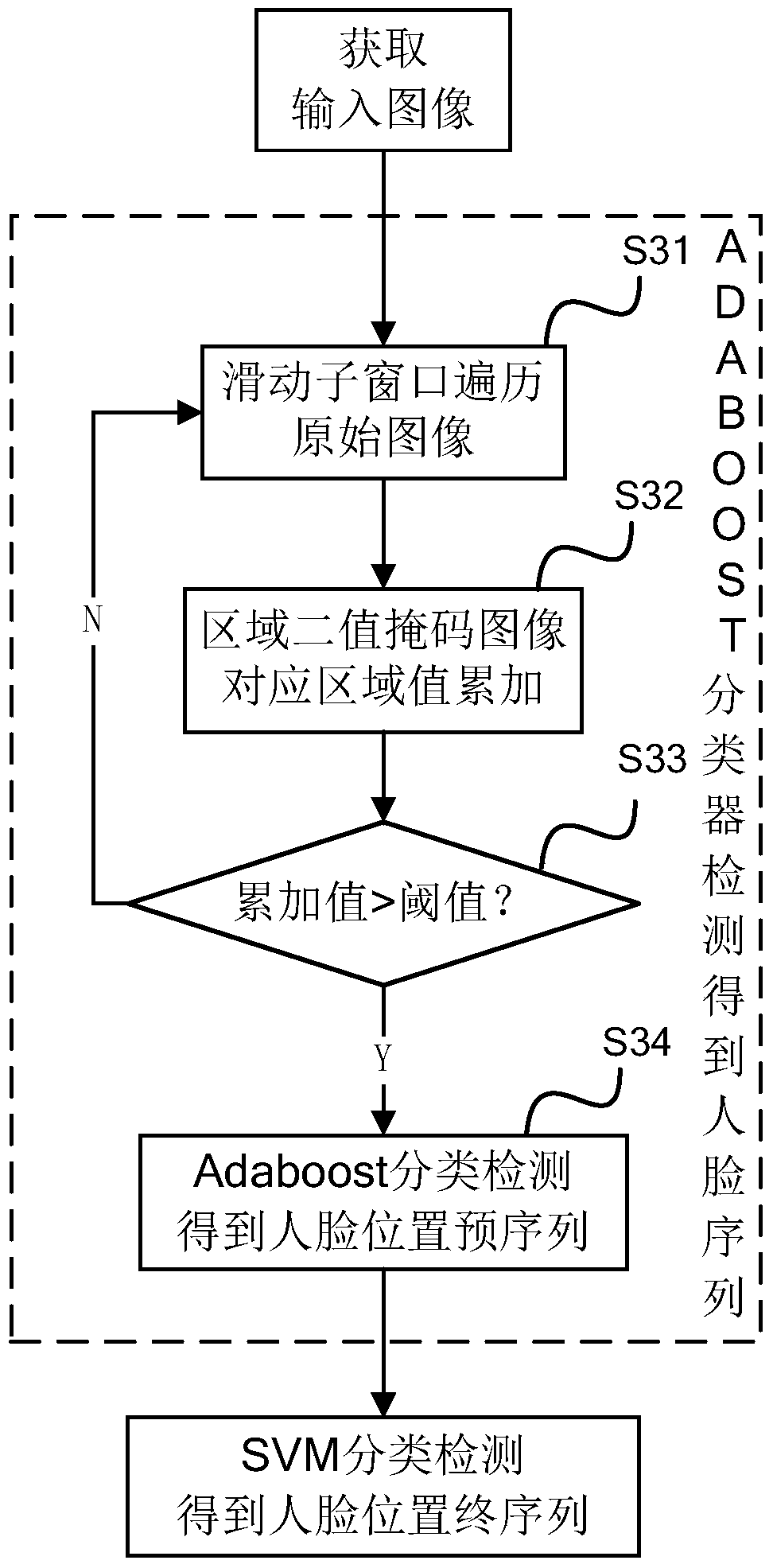

Video face detection method and device

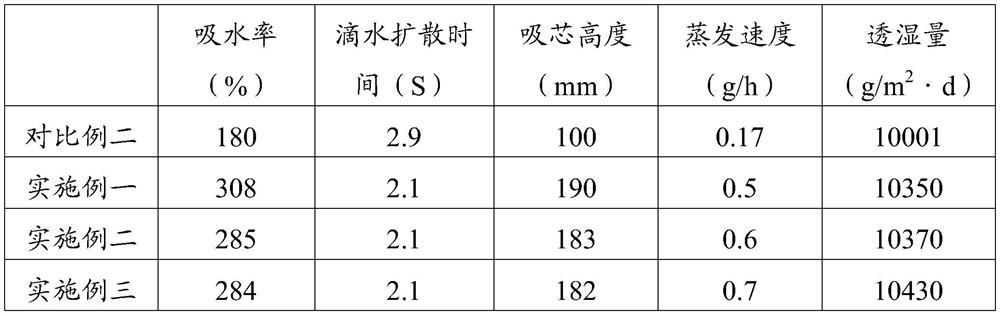

ActiveCN105184244BReduce hierarchyHigh speedCharacter and pattern recognitionPattern recognitionFace detection

The present invention provides a video human face detection method and device, wherein the method includes a human face detection process; the human face detection process includes steps, S1) inputting a video image frame, using the image frame as an original image; S3) using haar or The lbp feature uses the adaboost classifier to detect the original image to obtain the pre-sequence of the face position; S4) input the pre-sequence of the face position into the SVM classifier for detection, and obtain the final sequence of the face position. In the present invention, two classifiers, adaboost and SVM, are organically combined and applied to video face detection, so that the levels of adaboost classifiers can be greatly reduced compared with those used alone, thereby effectively improving the speed of video face detection, and further improving the detection results of adaboost The SVM classifier is used for secondary classification to ensure the detection effect of fast detection.

Owner:SHENZHEN INFINOVA

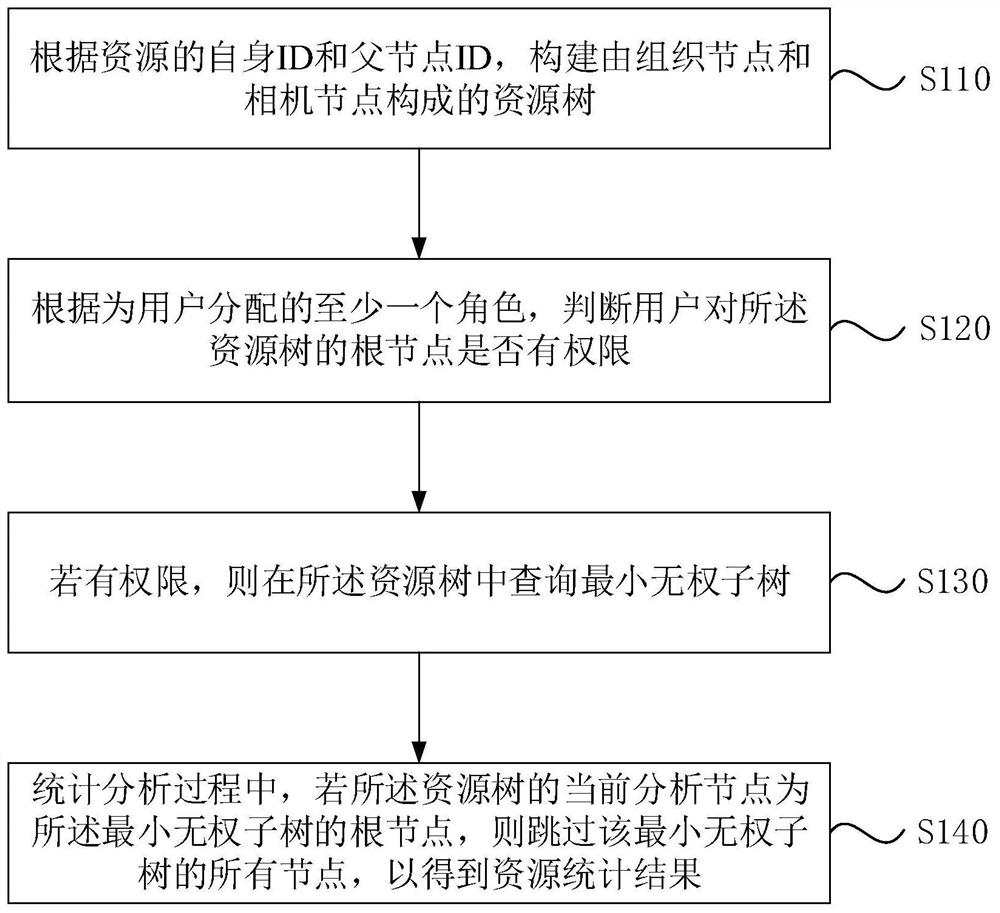

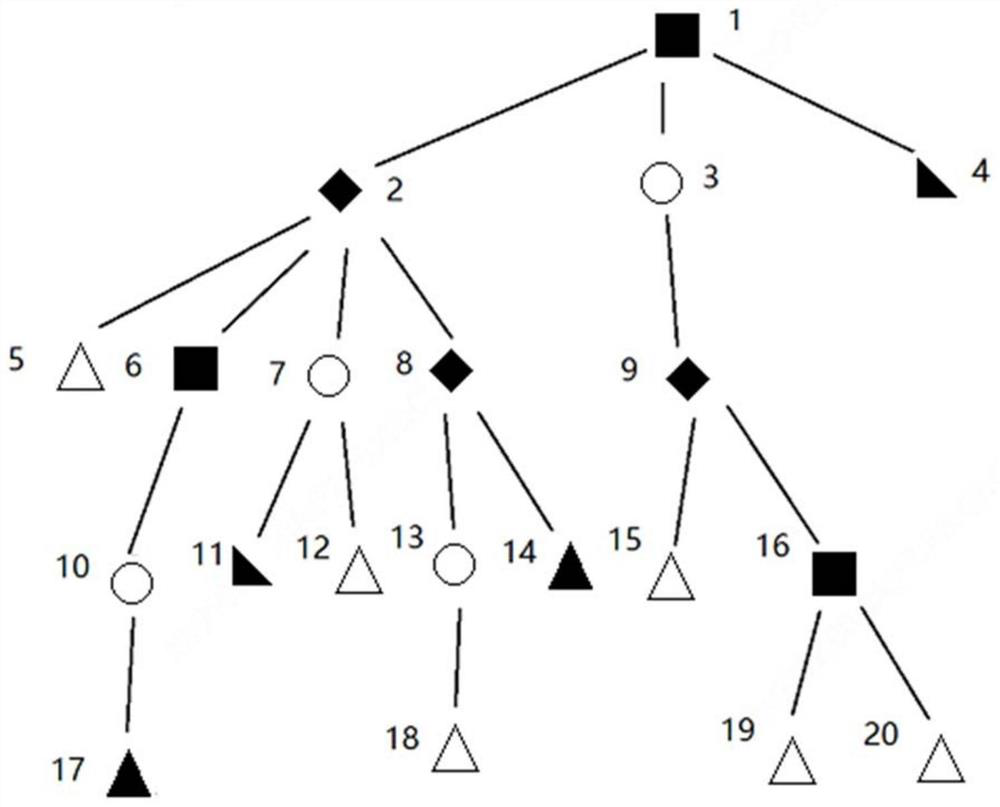

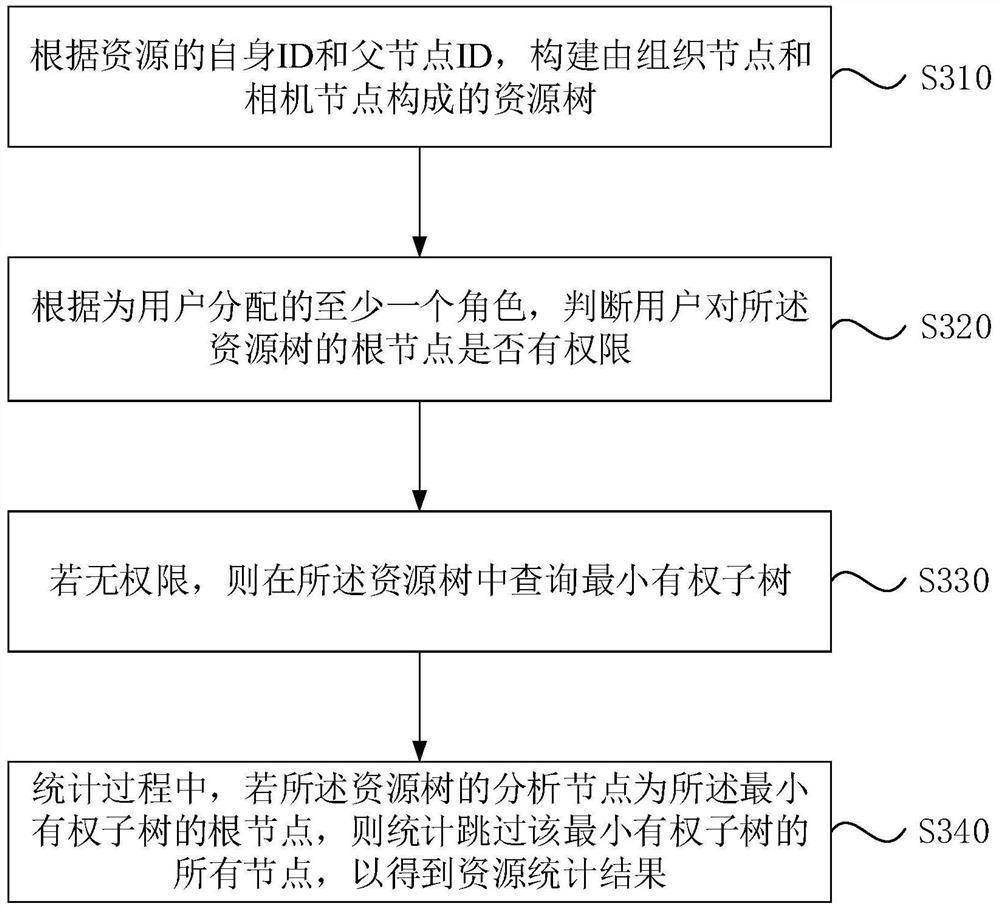

Resource statistical method and device based on resource tree permission, medium and electronic equipment

PendingCN114691671AReduce the number of nodes and levels traversedSmall amount of calculationSpecial data processing applicationsDatabase indexingCurrent analysisComputer network

The embodiment of the invention discloses a resource statistics method and device based on resource tree permission, a medium and electronic equipment. Constructing a resource tree composed of organization nodes and camera nodes according to the ID of the resource and the ID of the father node; according to at least one role allocated to the user, judging whether the user has permission to a root node of the resource tree or not; if the resource tree has the permission, querying a minimum unweighted sub-tree in the resource tree; and in the statistical analysis process, if the current analysis node of the resource tree is the root node of the minimum unweighted sub-tree, skipping all nodes of the minimum unweighted sub-tree to obtain a resource statistical result. By adopting the scheme, when the camera resources in the resource tree are counted, traversed nodes and levels can be reduced through the configured permission, meanwhile, permission identification does not need to be performed again during traversal, the calculation amount required by resource statistics is reduced, and the statistical efficiency is improved.

Owner:ZHEJIANG UNIVIEW TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com