A multi-workpiece ion beam polishing system and method

An ion beam and multi-workpiece technology, applied in the field of ion beam polishing, can solve the problems of not effectively improving processing efficiency, limited clamping positions of fixtures, affecting production efficiency, etc., so as to reduce the level of moving devices and reduce the disassembly and assembly of workpieces. , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

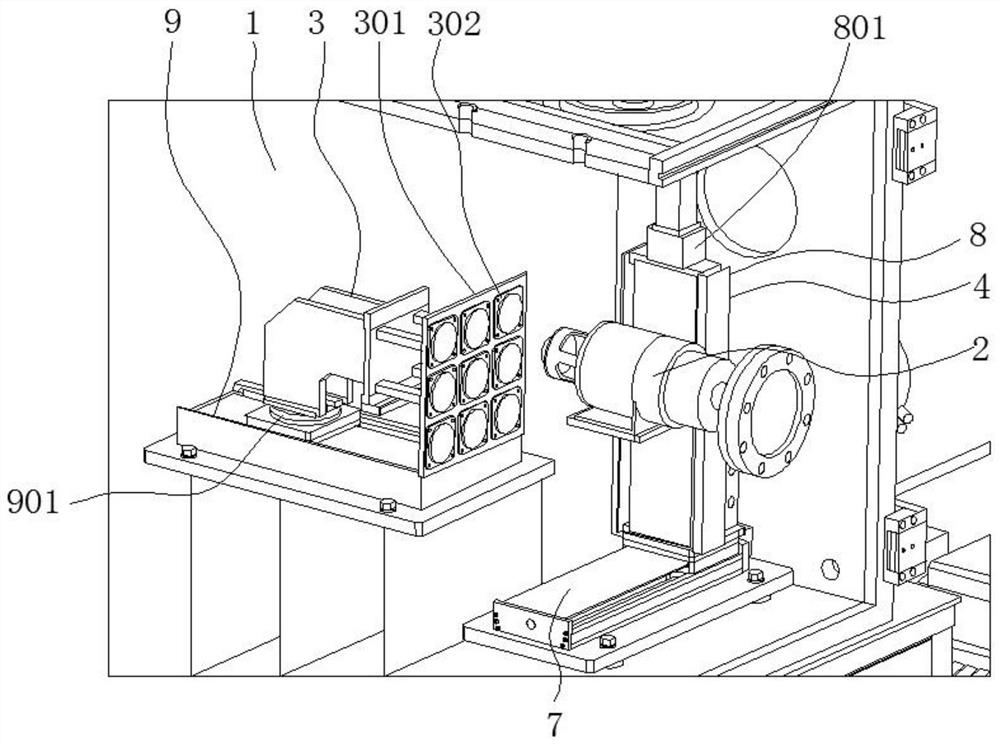

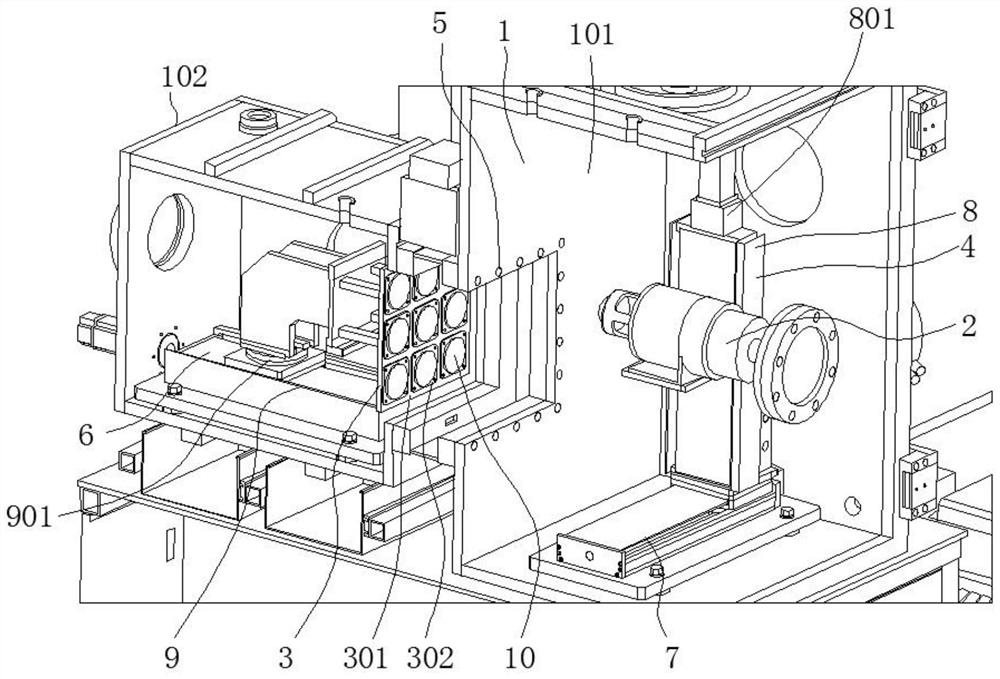

[0041] see figure 1 , image 3 , Figure 4 , the present embodiment is a multi-workpiece ion beam polishing system, the vacuum chamber is a single vacuum chamber, and the vacuum chamber 1 is provided with an ion source 2 required for generating an ion beam, a clamp 3 for clamping a workpiece 10, and a The controlled motion mechanism 4 holds a plurality of workpieces 10 on the fixture 3 at the same time.

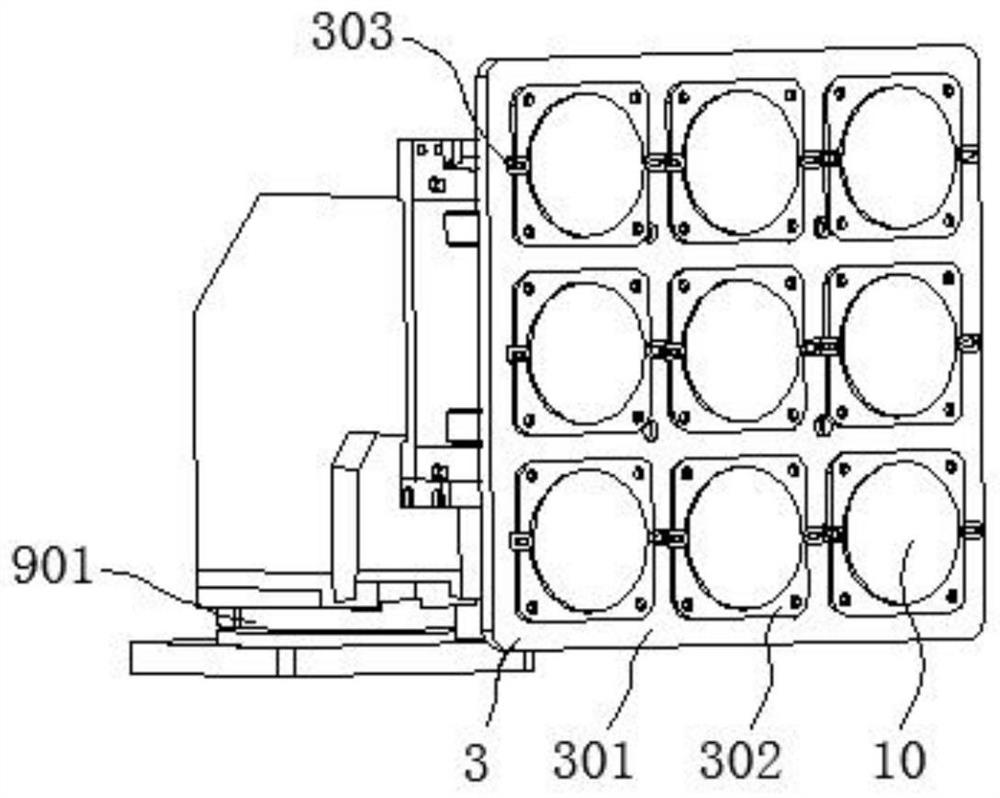

[0042] In this embodiment, the jig 3 includes a clamping plate 301, on which a plurality of positioning plates 302 are connected, and the positioning plate 302 is provided with a structure for fixing the workpiece.

[0043] In this embodiment, the positioning plate 302 is determined according to the shape of the workpiece 10 and is set in a circular shape, and the structure for fixing the workpiece is a latch 303 .

[0044] In this embodiment, the motion mechanism 4 includes an X-direction motion unit 7 , a Y-direction motion unit 8 , and a Z-direction motion unit 9 that a...

Embodiment 2

[0060] The difference from Embodiment 1 is that the vacuum chamber in this embodiment is a double vacuum chamber, and the vacuum chamber 1 is divided into a main vacuum chamber 101 and a secondary vacuum chamber 102, and a control main chamber is installed between the main vacuum chamber 101 and the secondary vacuum chamber 102. , The gate valve 5 for switching on and off the auxiliary vacuum chamber, the ion source 2 is located in the main vacuum chamber 101, and the fixture 3 for clamping multiple workpieces is installed in the auxiliary vacuum chamber 102 to load and unload multiple workpieces.

[0061] In this embodiment, the main and auxiliary vacuum chambers are provided with docking guide rails 6 , and the multi-workpiece fixture 3 enters and exits the main vacuum chamber from the auxiliary vacuum chamber through the docking guide rails 6 .

[0062] In this embodiment, the Z-direction movement unit 9 and the docking guide rail 6 are the same device.

[0063] In this emb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com