Method for improving cut-off wavelength of indium arsenide/gallium antimony superlattice infrared detector material, indium arsenide/gallium antimony type II superlattice and application thereof

An infrared detector and cut-off wavelength technology, which is applied in semiconductor devices, photovoltaic power generation, electrical components, etc., can solve the problems of high growth cost, many intra-crystal interfaces, and low service life of production equipment, and achieve the effect of improving the detection wavelength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with specific embodiment and accompanying drawing, the present invention will be further described:

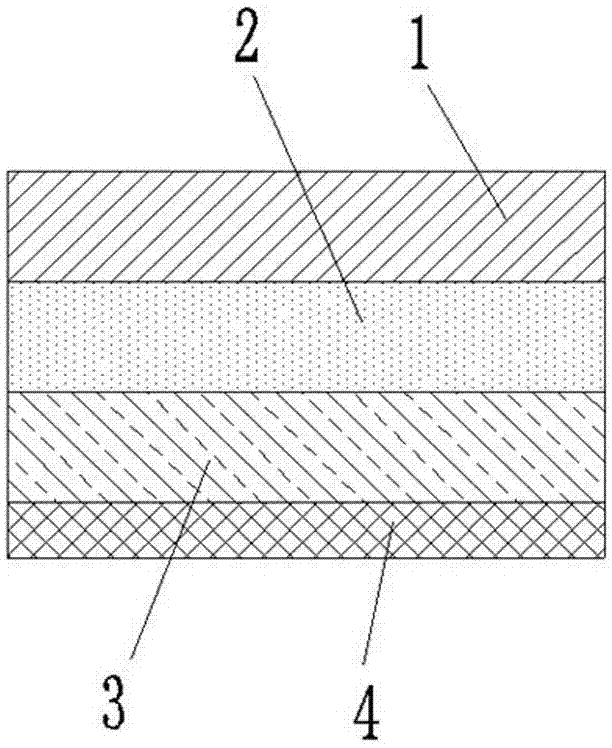

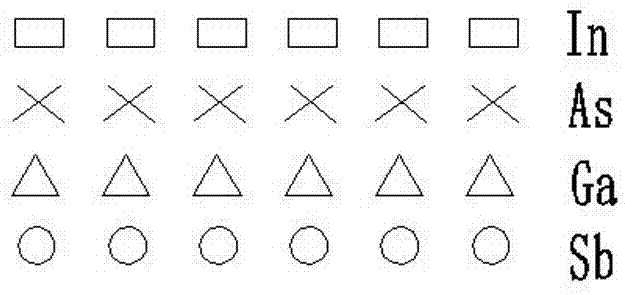

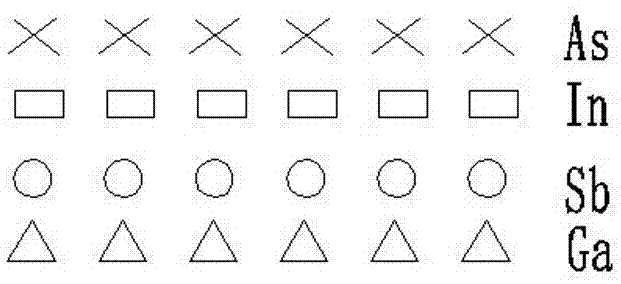

[0025] For the type II superlattice composed of InAs / GaSb, it has two basic material components, InAs and GaSb, for the type II superlattice material composed of InAs and GaSb, the arrangement of its elements has certain rules property, that is, the elements of Group V and Group III are arranged alternately in sequence, that is, one layer of Group V elements, one layer of Group III elements, one layer of Group V elements, and one layer of Group III elements are arranged in sequence, or one layer of Group III elements, one layer of Group III elements The elements of group v, one layer of group III elements and one layer of group v elements are arranged alternately in sequence. With different element arrangements, the InAs layer and the GaSb layer in the InAs / GaSb II superlattice form different interfacial layers in the unit cell, such as figure 2 A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com