Sheet cyclic heating device of metal decorating machine

A technology of cycle heating and iron printing machine, which is applied to printing machines, general parts of printing machinery, printing, etc. It can solve the problems of easy discoloration or scratching of surface patterns, affecting human health, surface stickiness, etc., and achieves a hard coating layer Durable, simple structure, effect of improving adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

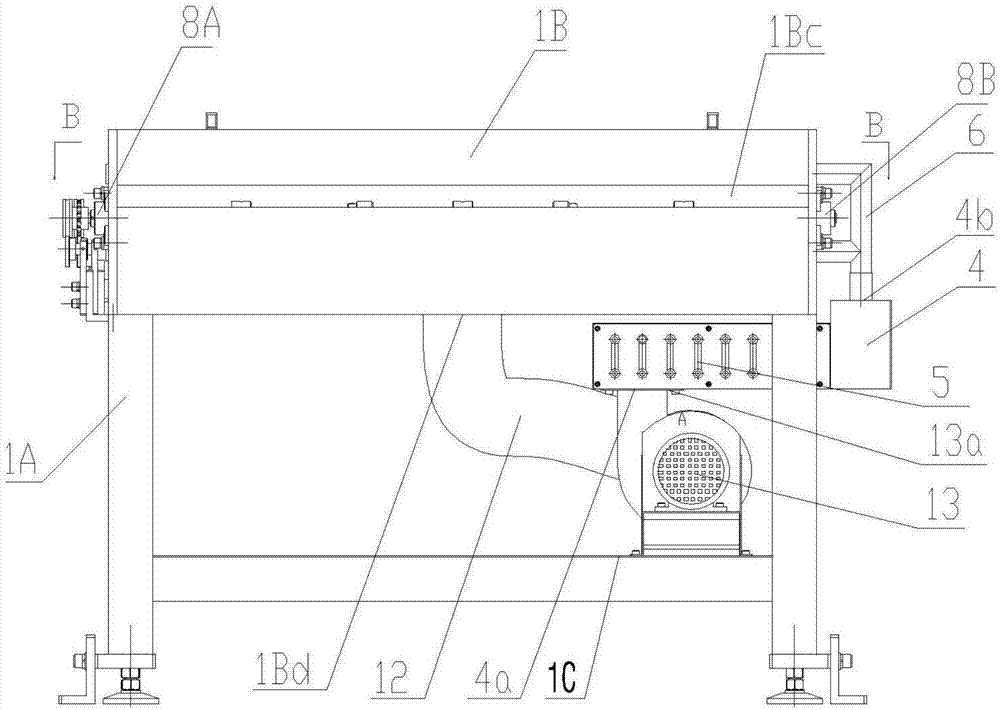

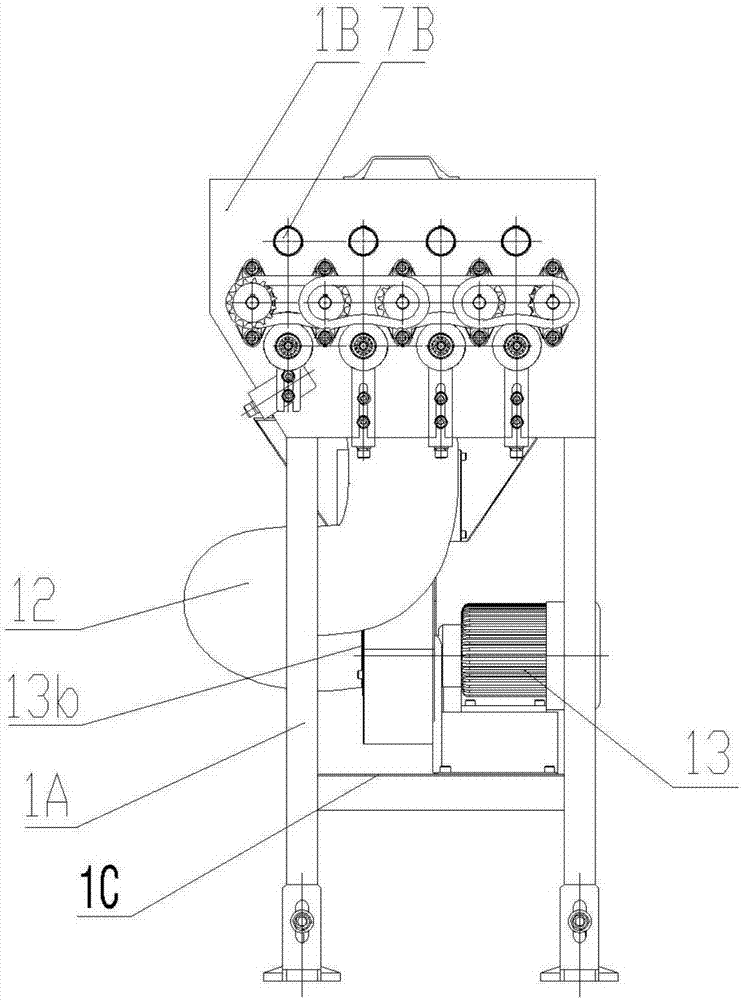

[0032] The structural features and beneficial effects of the present invention will be further described below in conjunction with the accompanying drawings.

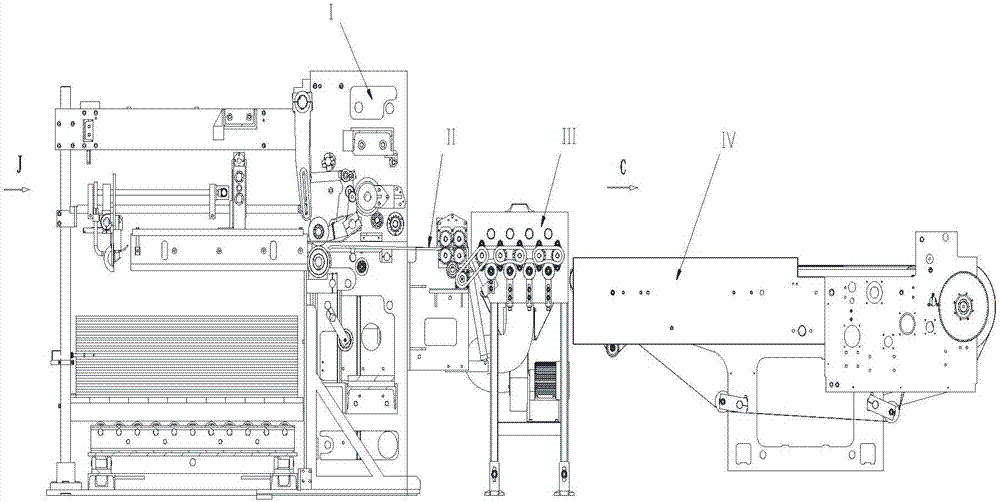

[0033] see figure 1 and figure 2 , with reference to Figure 3-Figure 9 , the figure shows a sheet metal circulation heating device related to the present invention, which is positioned and connected between the cleaning device II and the pushing mechanism IV, and is movably connected with the cleaning device II through a cross-connection drive mechanism K; The key technical solutions adopted are:

[0034] The sheet material circulation heating device of the iron printing machine involved in the present invention integrally includes a lower leg 1A and an upper heating box 1B; the longitudinal sides of the heating box 1B are respectively horizontally provided with a sheet material P feeding port 1Bj connected with the cleaning device II , the sheet material P outlet 1Bc connected with the pushing mechanism IV, such a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com