Sheet preheating horizontal conveyance upwarping control mechanism for metal decorating machine

A technology of horizontal conveying and control mechanism, applied in the direction of conveyors, conveyor objects, printing machines, etc., can solve the problems affecting the smooth operation of sheets, and achieve the effects of simple structure, stable operation and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

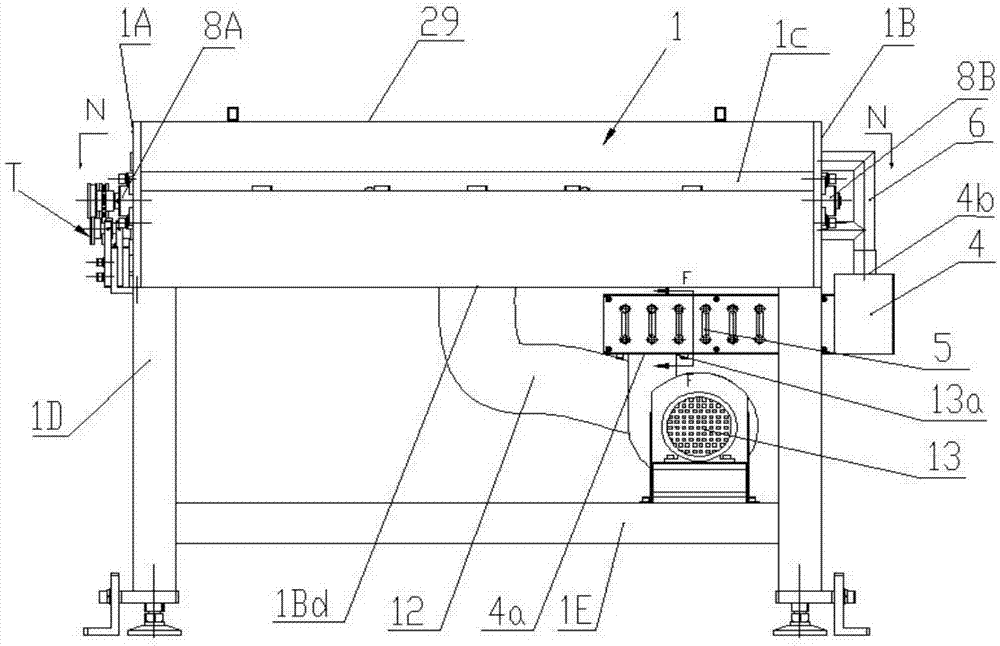

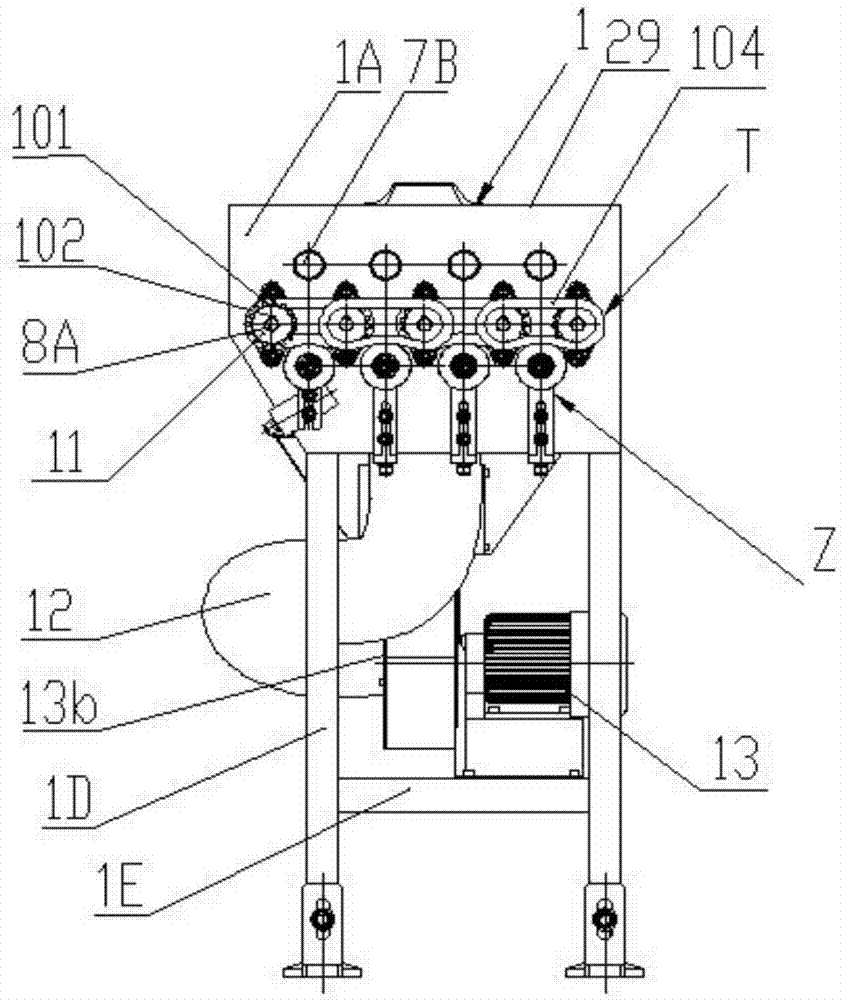

[0045] The structural features and beneficial effects of the present invention will be further described below in conjunction with the accompanying drawings.

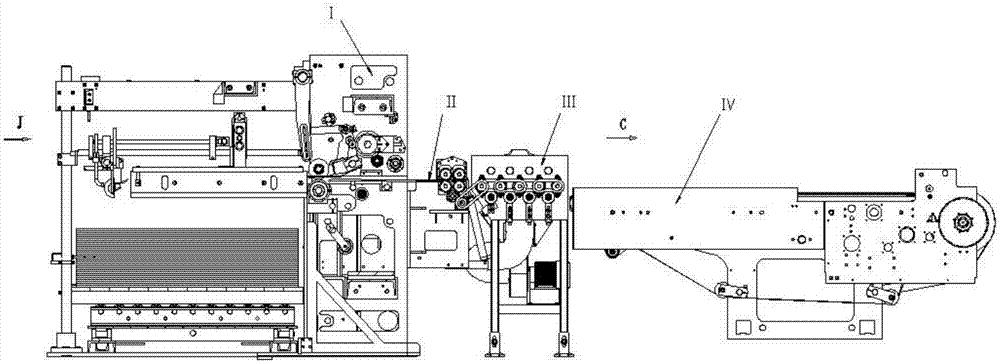

[0046] see figure 1 and figure 2 , with reference to Figure 3-Figure 13 , the figure shows a sheet preheating horizontal conveying control mechanism for an iron printing machine related to the present invention, and the key technical solution adopted by it is:

[0047] The sheet preheating horizontal conveying control mechanism of the iron printing machine related to the present invention includes a sheet preheating device III positioned and connected between the cleaning device II and the pushing mechanism IV of the iron printing machine; the sheet preheating device III includes a The drying box 1 on its upper part and the circulating heating mechanism connected with the drying box 1;

[0048] The longitudinal sides of the drying box 1 are respectively horizontally provided with a sheet P feed port 1j connected wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com