Propulsion propeller and pneumatic ship not likely to roll over during high-speed navigation

A technology for propellers and ships, which is applied in the direction of rotating propellers, ship propulsion, ship parts, etc., can solve the problems of high use cost, large resistance, high resistance, etc., and achieve the effect of reasonable design, reduced resistance and small water splash

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

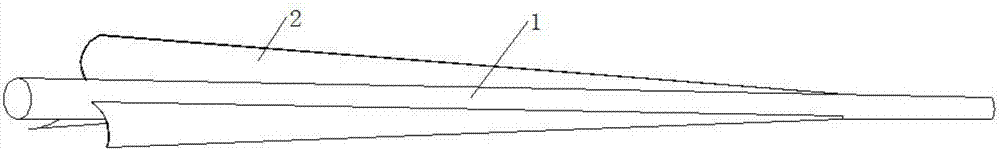

[0043] Embodiment one: if figure 1 As shown, this embodiment provides a propulsion propeller, which is characterized in that: it includes a main shaft 1 and at least three blades 2 with the same specifications;

[0044] At least three of the above-mentioned blades 2 are circumferentially and evenly arranged on the outer periphery of the main shaft 1, and extend circumferentially from a position close to one end of the above-mentioned main shaft 1 to a position close to the other end thereof, and the cross-section of each of the above-mentioned blades 2 is arc-shaped, And the distance between the edge of each blade 2 on the side away from the main shaft 1 and the axis of the main shaft 1 gradually increases from one end of the main shaft 1 to the other end.

[0045]During use, the main shaft 1 of the propeller is driven by the driving mechanism of the ship to rotate. Since the blades 2 are arranged along the axial direction of the main shaft 1, and the cross-sectional area grad...

Embodiment 2

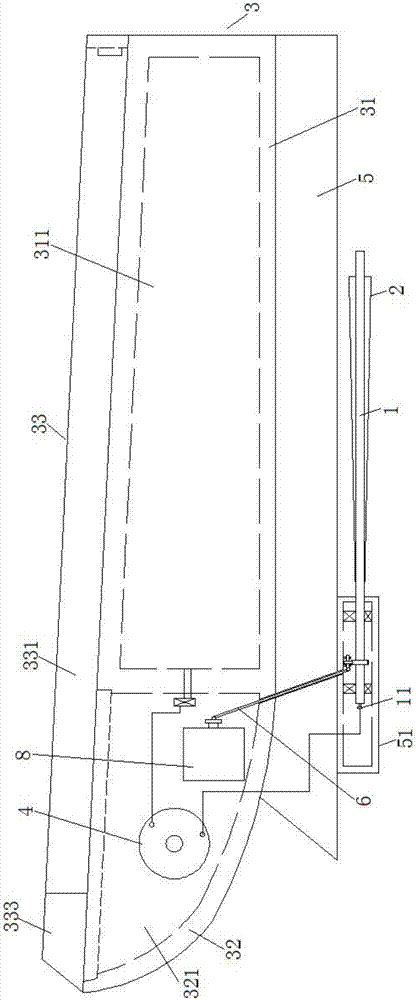

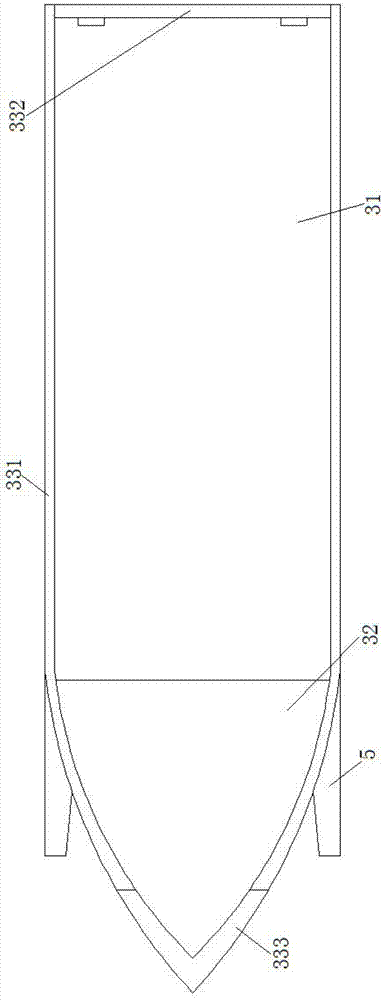

[0048] Embodiment two: if Figure 2-6 As shown, the present embodiment provides an aerodynamic boat that is not prone to rollover during high-speed navigation, including a hull 3, two air generators 4, two propulsion propellers and two universal joint transmission shafts 6;

[0049] Above-mentioned hull 3 is made of integrally formed hull 31 and bow 32;

[0050] Both sides of the bottom of the above-mentioned hull 31 are symmetrically provided with two accumulation wings 5, the front end of each of the above-mentioned accumulation wings 5 all extends to the above-mentioned bow 32, and the rear end extends to be flush with the rear end of the above-mentioned hull 31 ;

[0051] The lower end of the front end of each of the above-mentioned backlog wings 5 is integrally formed with an internal hollow connection portion 51, and the two above-mentioned propulsion propellers are arranged in one-to-one correspondence with the two above-mentioned connection portions 51, and each o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com