Leading edge load mounting system of flying wing stealth unmanned aerial vehicle

A technology for installing systems and drones, applied in the field of drones, can solve the problems of inconvenient installation of stealth aircraft loads, inability to reflect radar waves, etc., and achieve the effect of reducing reflection and ensuring stealth performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be explained and described in detail below in conjunction with the accompanying drawings and specific embodiments.

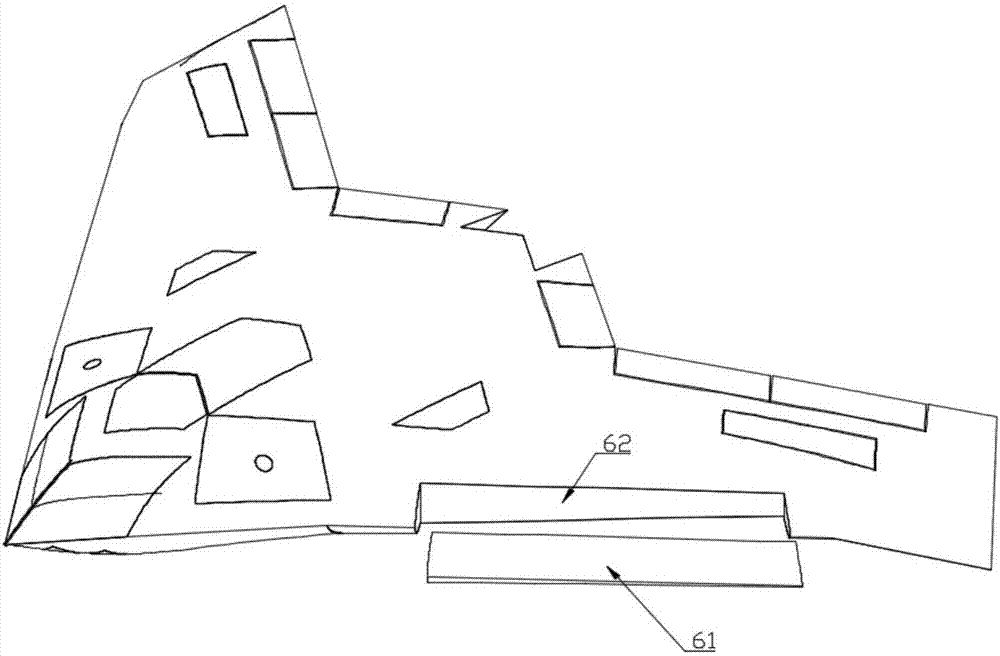

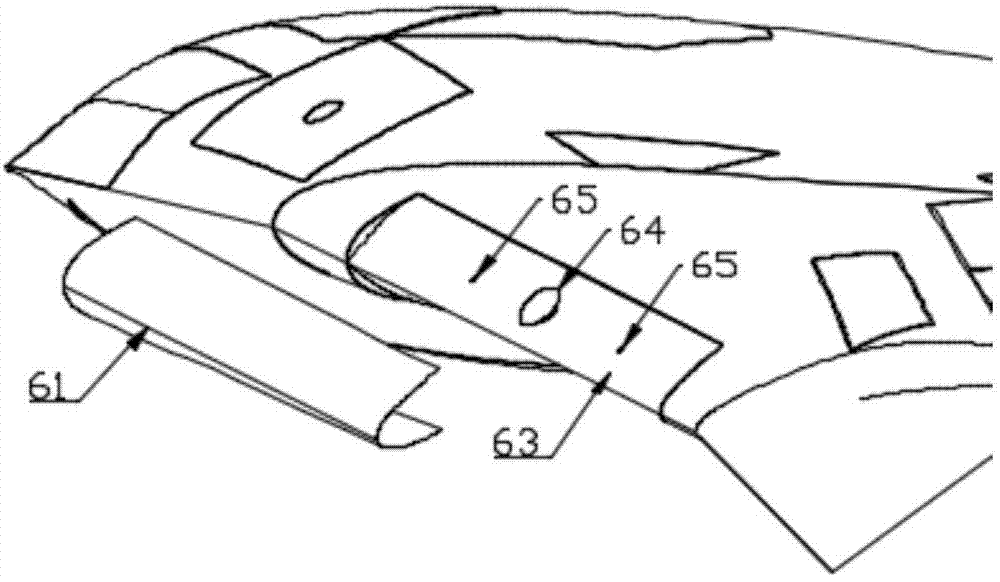

[0020] like figure 1 and figure 2 As shown, the leading edge load installation system of the flying wing layout stealth UAV includes a concave installation gap arranged on the leading edge of the wing, a front beam 62, a leading edge wedge 63 and a leading edge load hatch 61, and a front beam 62 Installed at the bottom of the installation gap, the leading edge wedge 63 is arranged on the front beam 62 and covers the front beam 62, the leading edge load hatch 61 is installed on the leading edge wedge 63 and smoothly transitions with the fuselage, and the leading edge wedge 63 is provided with a mounting hole 65 for installing the load 64. The leading edge wedge 63 is wedge-shaped protruding outwards and forms a V-shaped cavity with the leading edge load hatch 61. The leading edge wedge 63 Adopt conductive materials, such as: f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com