Automatic wire arrangement compensation device for stainless steel wires

A stainless steel wire, automatic compensation technology, used in transportation and packaging, transportation of filamentous materials, thin material processing, etc. Reasonable design, lower production cost, and lower frequency of replacement of the I-wheel body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in combination with specific embodiments.

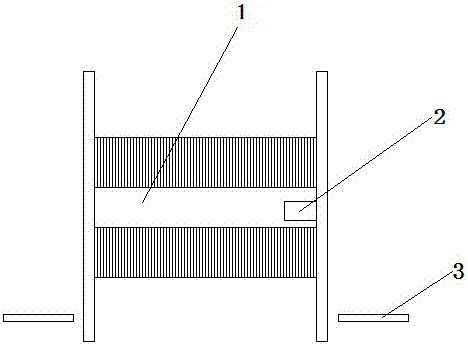

[0019] Such as figure 1 As shown, a stainless steel wire automatic compensation cable arrangement mainly includes an I-wheel body 1, a PLC control system 2 and a push rod 3, and the push rods 3 are respectively located on both sides of the wing plate of the I-wheel body 1, and The PLC control system 2 is respectively provided with a PLC terminal, a rotational speed sensing device, an accessory control device and an alarm device.

[0020] One end of the push rod 3 is in contact with the I-wheel body 1, and there is a resistance layer at the contact end of the push rod 3 and the I-wheel body 1, and there are some protruding friction particles on the surface of the resistance layer. The PLC control system 2 is connected by wires.

[0021] The PLC control system 2 is located on the central axis of the I-wheel body 1. When the speed sensing device transmits the sensed speed to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com