Paint removing device for vacuum plating of automobile hub

A technology of vacuum plating for automobile wheels, applied in vacuum evaporation plating, sputtering plating, ion implantation plating, etc., can solve the problems of endangering human health, low production efficiency, and excessive dust, and achieve safe and fast picking and placing of workpieces , good paint removal effect, temperature controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

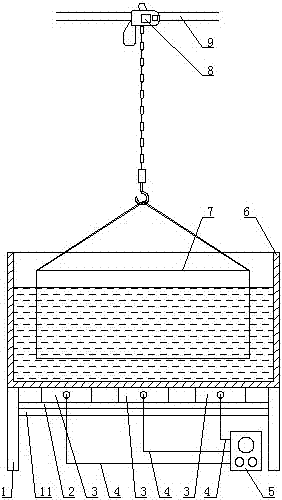

[0007] see figure 1 , the present invention comprises a frame 1, a temperature-resistant asbestos board 2, a wire 4, an electric control box 5, a paint stripping box 6, a mesh wire basket 7, an electric hoist 8, a track 9 and several electric heating plates 3, the machine The frame 1 is provided with a supporting plate 11, the temperature-resistant asbestos board 2 is mounted on the supporting plate 11 of the frame 1, the paint stripping box 6 is mounted on the frame 1, and the electric heating plate 3 is mounted on a temperature-resistant Between the asbestos board 2 and the bottom of the paint stripping box 6, the electric hoist 8 is hung on the track 9, and the electric hoist 8 can walk along the track 9, and the mesh wire basket 7 is hung on the bottom of the electric hoist 8 On the hook, the electric control box 5 is connected with the electric heating plate 3 through the wire 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com