Dyeing equipment for regenerated polyester yarns

A technology for regenerating polyester and dyeing equipment, which is applied in the directions of processing textile material equipment configuration, liquid/gas/vapor yarn/filament processing, processing textile material containers, etc., to achieve temperature control, improve work efficiency, and increase the effect of boiling temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

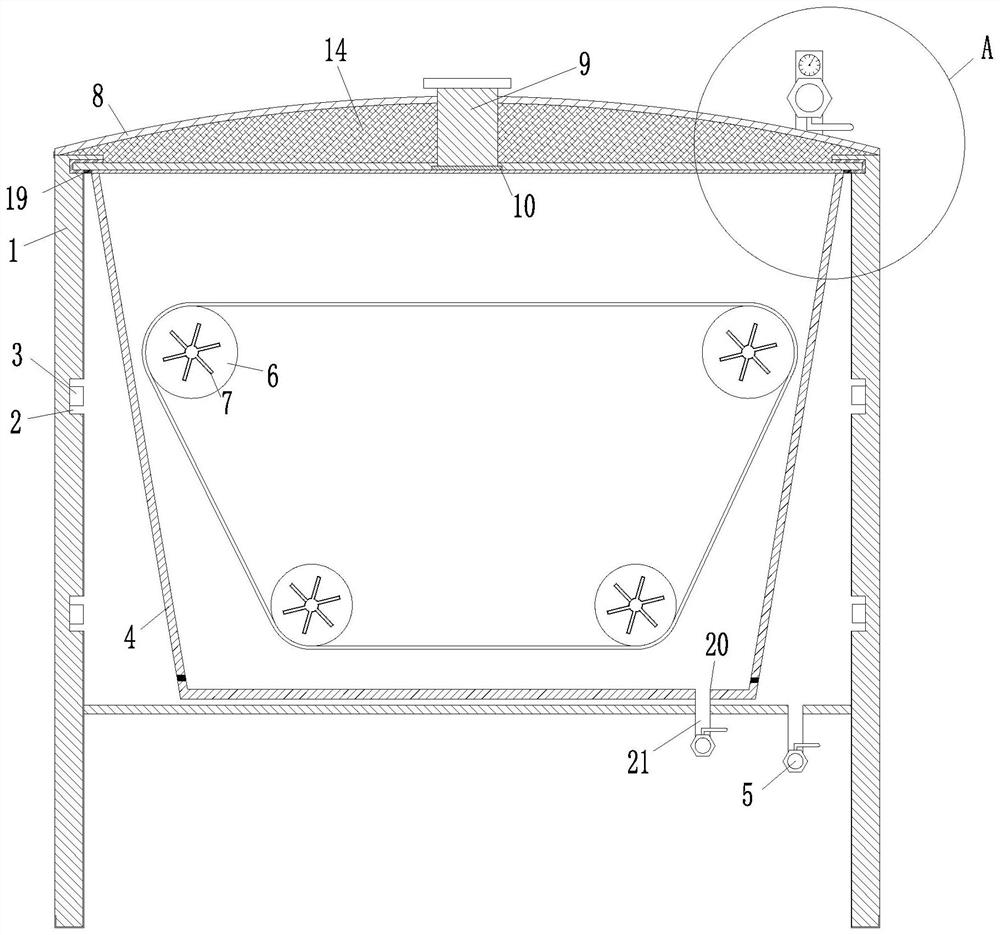

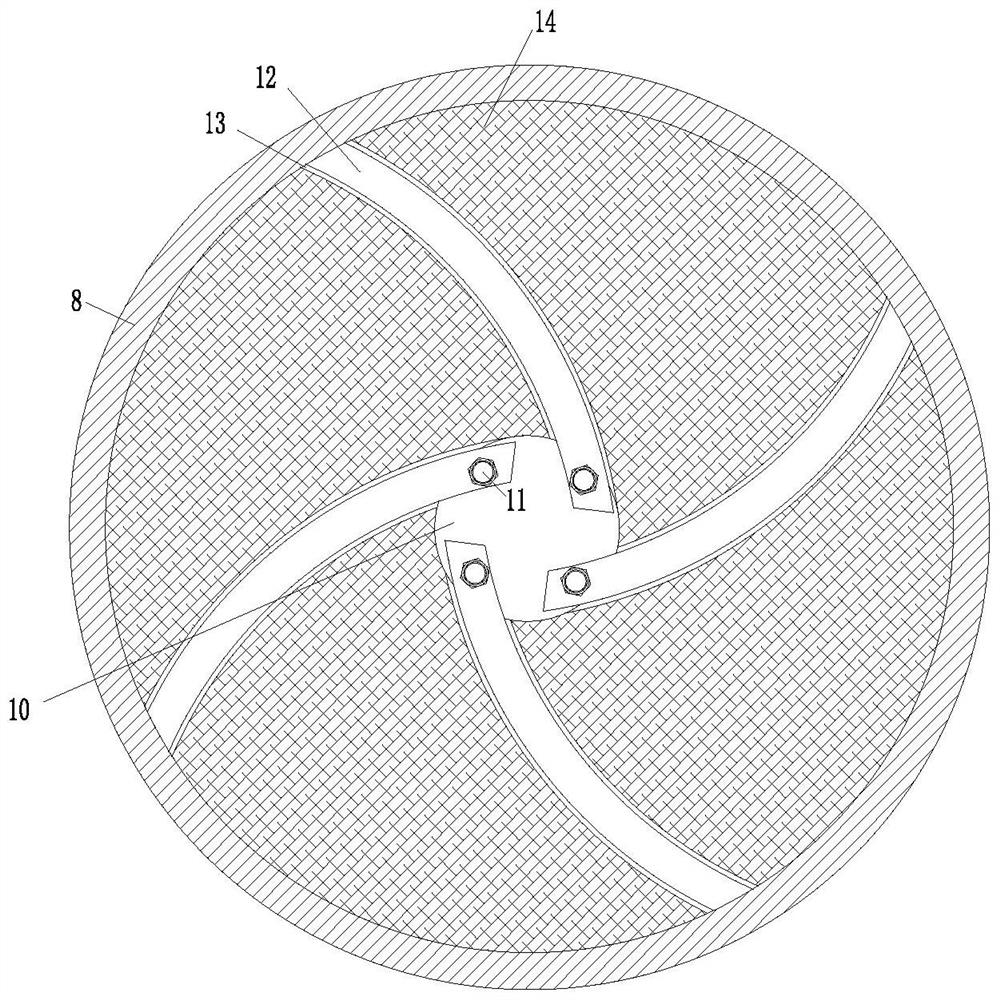

[0042] As a specific embodiment of the present invention, there is a gap between the bottom of the waterproof layer 4 and the bottom of the dyeing cylinder body 1;

[0043] There is a gap between the bottom of the waterproof layer 4 and the bottom of the dyeing cylinder body 1. When water is injected into the dyeing cylinder body 1, the water can fill the outside of the waterproof layer 4, so that the water can fully wrap the waterproof layer 4. When the heating device 3 heats the water, the water can fully heat the dye liquor through the waterproof layer 4, which ensures that the dye liquor is heated evenly and effectively improves the dyeing effect.

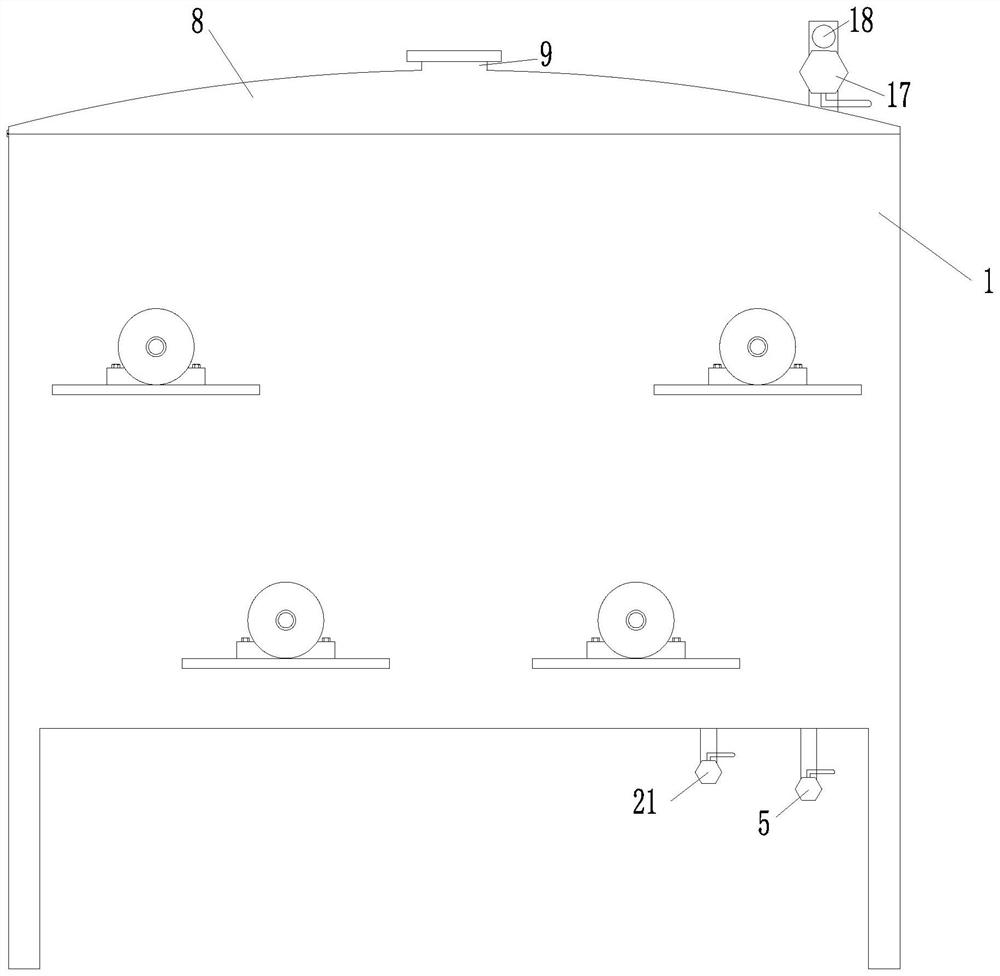

[0044] As a specific embodiment of the invention, the inner side wall of the dyeing cylinder body 1 is rotatably connected with more than one guide roller 6, and a plurality of guide rollers 6 all penetrate through the waterproof layer 4 and are rotatably connected with the side wall of the waterproof layer 4, and the ends of the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com