New flat-plate heat sink for solar tower power generation and systems using it

A power generation system and heat absorber technology, applied in solar heating systems, working fluids of solar collectors, solar thermal power generation, etc., can solve problems such as good temperature uniformity, high heat transfer efficiency, low center of gravity and volume of light absorbing panels problems, to achieve excellent heat transfer characteristics, good safety, and reduce thermal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to further illustrate the invention content, features and functions of the present invention, it will be described in detail in conjunction with the accompanying drawings and specific embodiments, but the present invention is not limited to these embodiments.

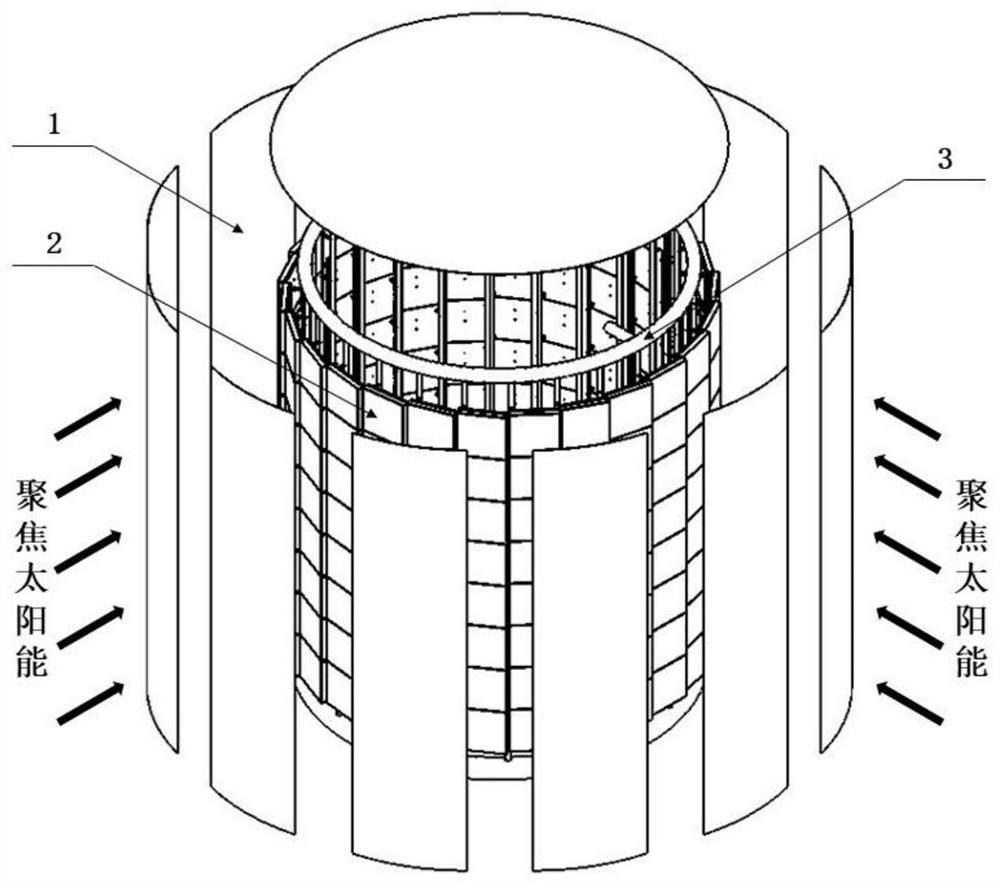

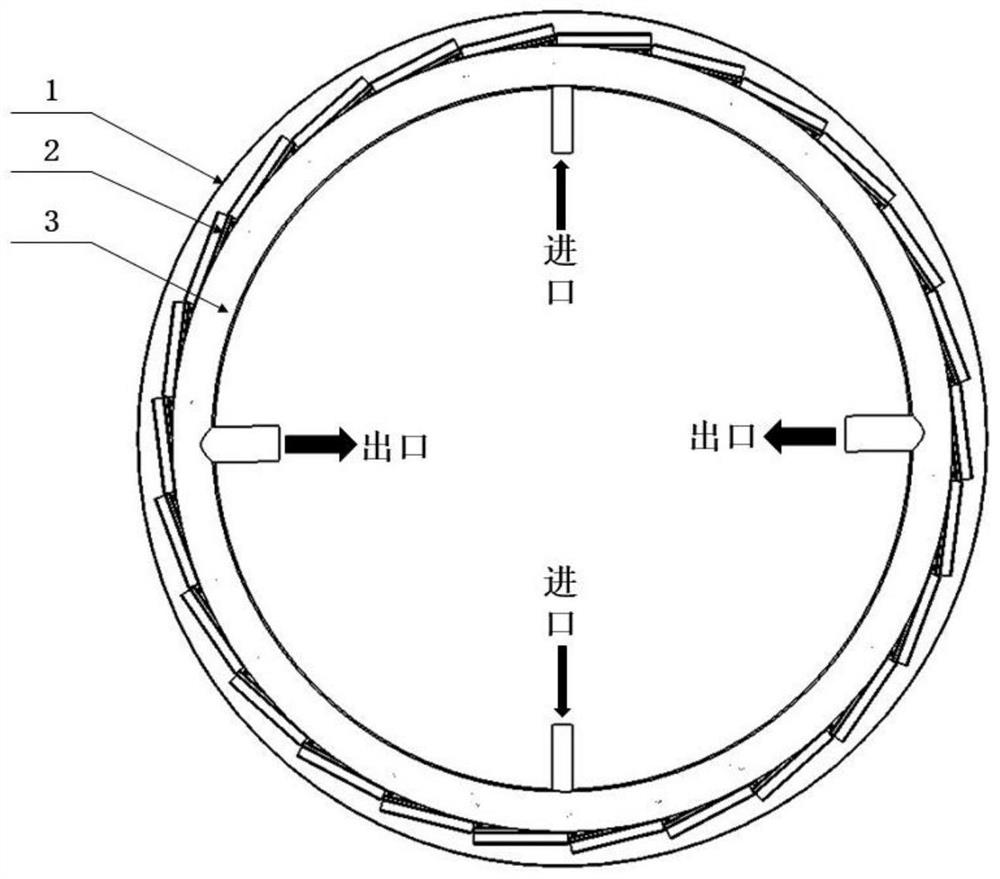

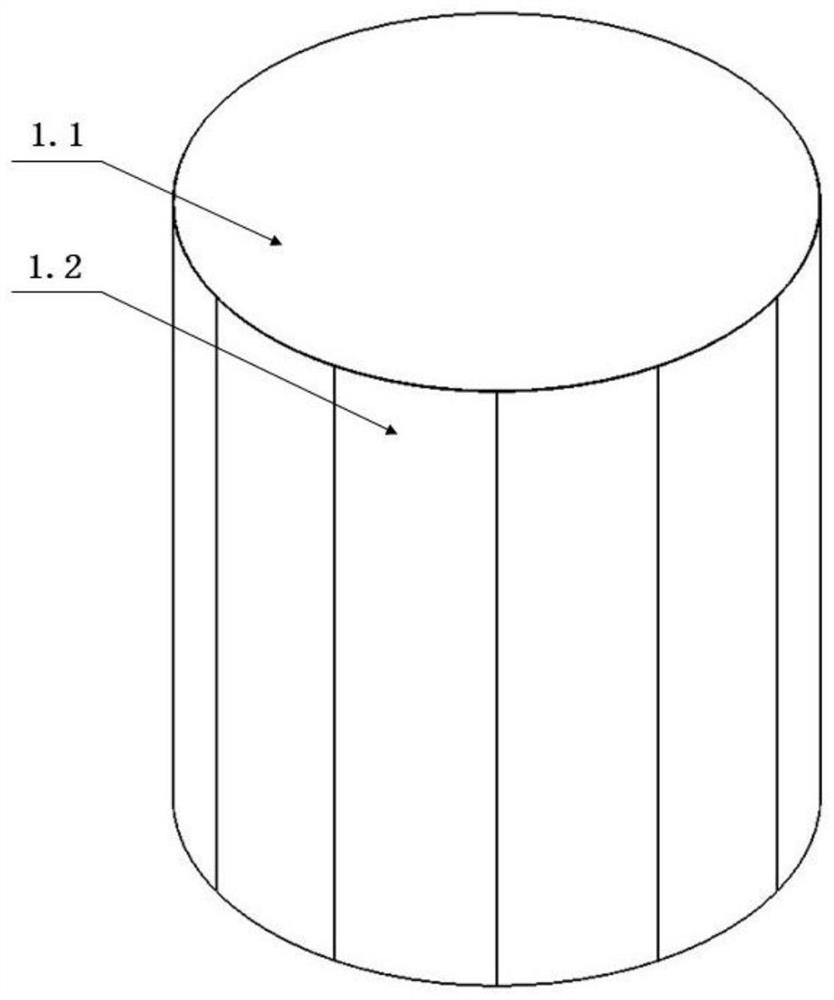

[0037] Such as figure 1 and Figure 4 As shown, a new type of flat heat absorber for solar tower power generation and a system using it, the system includes a windshield 1, a flat heat absorber 2 and a circulation pipeline 3. In the flat heat absorber 2, the heat pipe principle is adopted for indirect heat transfer, so as to achieve better temperature uniformity performance of the light absorbing plate 2.1. During the working process, the focused high-energy-flux-density solar energy passes through the windshield 1, irradiates on the light-absorbing plate 2.1 of the flat heat absorber 2, and is absorbed by the light-absorbing coating 2.1.1 and converted into heat energy, which is transmitted to the lig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com