Polyurethane heat insulation aluminum alloy sectional material and manufacturing process thereof

A technology of aluminum alloy profiles and polyurethane, which is applied in the direction of building structures, windows/doors, building components, etc., can solve problems such as not being able to meet requirements, and achieve the effects of reducing quality, not easily deformed, and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

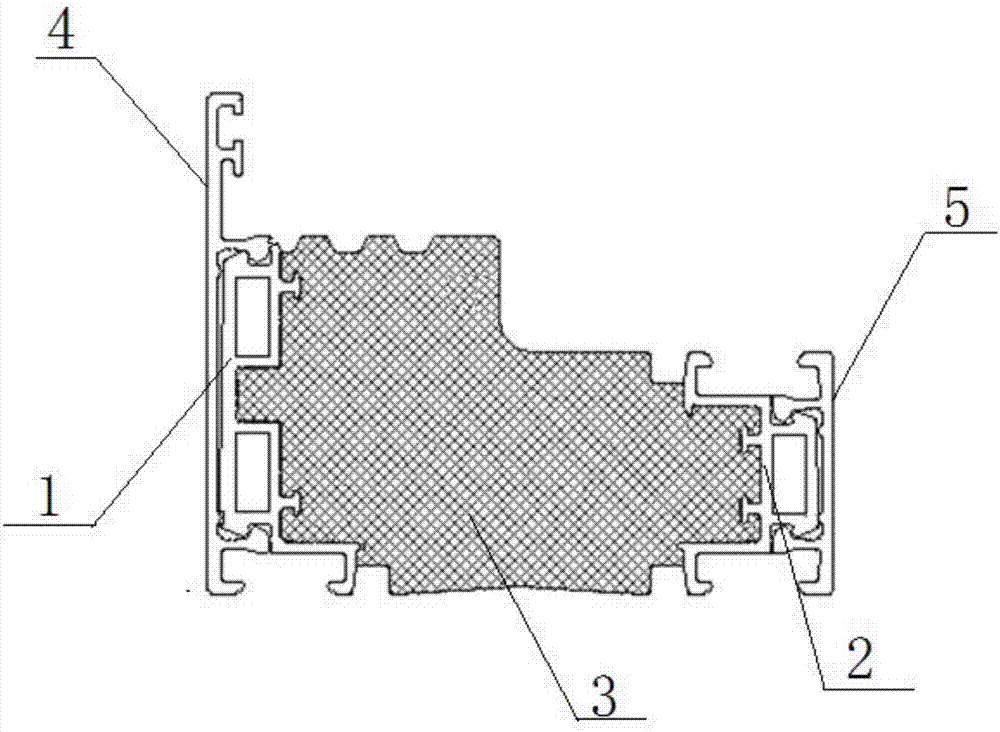

[0032] Such as figure 1 As shown, the present invention is a polyurethane heat insulating aluminum alloy profile, which includes a first inner profile 1, a second inner profile 2 and a polyurethane heat insulating material 3, and the polyurethane heat insulating material 3 is arranged on the first inner profile 1 Between the second inner profile 2 and with the first inner profile 1 and the second inner profile 2 through pouring and foaming to form an integrated profile core; both sides of the profile core are provided with a first outer core by rolling Profile 4 and second outer profile 5 .

[0033] Both the surfaces of the first inner profile 4 and the second inner profile 5 are provided with corrugations, and the surfaces are all treated by steel shot sandblasting and anodic oxidation treatment process, and the polyurethane heat insulation material is added to the first inner profile and the second inner profile. Focus on.

[0034] The first inner profile 1 , the second in...

Embodiment 2

[0037] Such as figure 1 As shown, the present invention is a polyurethane heat insulating aluminum alloy profile, which includes a first inner profile 1, a second inner profile 2 and a polyurethane heat insulating material 3, and the polyurethane heat insulating material 3 is arranged on the first inner profile 1 Between the second inner profile 2 and with the first inner profile 1 and the second inner profile 2 through pouring and foaming to form an integrated profile core; both sides of the profile core are provided with a first outer core by rolling Profile 4 and second outer profile 5 .

[0038] Both the surfaces of the first inner profile 4 and the second inner profile 5 are provided with corrugations, and the surfaces are all treated by steel shot sandblasting and anodic oxidation treatment process, and the polyurethane heat insulation material is added to the first inner profile and the second inner profile. Focus on.

[0039] The first inner profile 1 , the second in...

Embodiment 3

[0042] Such as figure 1 As shown, the present invention is a polyurethane heat insulating aluminum alloy profile, which includes a first inner profile 1, a second inner profile 2 and a polyurethane heat insulating material 3, and the polyurethane heat insulating material 3 is arranged on the first inner profile 1 Between the second inner profile 2 and with the first inner profile 1 and the second inner profile 2 through pouring and foaming to form an integrated profile core; both sides of the profile core are provided with a first outer core by rolling Profile 4 and second outer profile 5 .

[0043] Both the surfaces of the first inner profile 4 and the second inner profile 5 are provided with corrugations, and the surfaces are all treated by steel shot sandblasting and anodic oxidation treatment process, and the polyurethane heat insulation material is added to the first inner profile and the second inner profile. Focus on.

[0044] The first inner profile 1 , the second in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com